|

|

#281 | |

|

Senior Member

Join Date: Jan 2012

Drives: '13 GBS Subaru BRZ

Location: Minneapolis, MN

Posts: 2,030

Thanks: 680

Thanked 664 Times in 382 Posts

Mentioned: 26 Post(s)

Tagged: 1 Thread(s)

|

Quote:

-Turnigy AquaStar T20 (229amps Max Load) 41V Max (I'll be running 36V) 1280 RPM/V or 730 RPM/V So a max for my configuration of 46K RPM -Turnigy SK3 EDF (110amps Max Load) 30V Max 1500 RPM/V Max of 45K RPM There are a lot of considerations here though. First the max RPM's are theoretical no-load speeds, and I have reason to believe the specs for the Aquastar are not correct. Pretty safe to assume the actual RPM will be less then the max possible for that motor. I'm also continuing to look at different motor options so if anyone sees something that might work let me know. Keep in mind we're looking for around 45K+ RPM and over 100 amps max load, probably closer to 150 amps. Edit: Another consideration is shaft diameter. For my current design the shaft diameter needs to be greater than 6.5mm and then will turned down to the fit the compressor wheel.

__________________

-Fortes fortuna adiuvat (Fortune favors the bold)

|

|

|

|

|

|

|

#282 |

|

Senior Member

Join Date: May 2013

Drives: FR-S 10 #103 AT

Location: NC

Posts: 1,519

Thanks: 101

Thanked 599 Times in 347 Posts

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

|

I find myself wondering about gearboxes, but I don't see anything capable of spinning at the rpm we need as being reliable or affordable. If you were to try simply offsetting the motor and using a couple of gears to increase the speed, I worry that the side load forces would make the turbine unstable. Could this be overcome by using three smaller motors as the points of a triangle with the turbine shaft in the center? The appropriate sized gears would ramp up the turbine rpm and the three driving gears might support the driven gear of the turbine and help keep it stable while three smaller motors added together could supply the necessary power to spin the thing.

Going further, a plate at each end of the assembly sandwiching the three motors could support a center shaft with a high rpm bearing at each end, allowing you to build it with the drive shaft diameter of your choice in the center. The output speed of the drive shaft would be established by the ratio of the gears. The design is simple and should be fairly rugged.

__________________

Necessity may be the mother of Invention but Desperation is quite often the father.

“Sex is like Bridge. If you don't have a good partner, you'd better have a good hand.” - Mae West Papa said, "son there's a lot of evil temptations out there. Best to try 'em all so you know which ones to avoid." |

|

|

|

|

|

#283 | |

|

Senior Member

Join Date: Jan 2012

Drives: '13 GBS Subaru BRZ

Location: Minneapolis, MN

Posts: 2,030

Thanks: 680

Thanked 664 Times in 382 Posts

Mentioned: 26 Post(s)

Tagged: 1 Thread(s)

|

Quote:

I think for my extra power needs (which is really none) the direct drive is going to be just fine. But I would be curious to see if someone else comes up with a geared designed. I'd probably even be willing to help with the design/CAD if someone has a good concept, but I'll leave building and testing to someone else. Edit: Also keep in mind as you try to get more compression that power has to come from somewhere. We're already talking about around 150 amps.

__________________

-Fortes fortuna adiuvat (Fortune favors the bold)

|

|

|

|

|

|

|

#284 |

|

Senior Member

Join Date: May 2013

Drives: FR-S 10 #103 AT

Location: NC

Posts: 1,519

Thanks: 101

Thanked 599 Times in 347 Posts

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

|

True enough. What they are seeing on the other thread is that even one psi with no overhead during boost yields a worthwhile increase. Keeping that in mind, how much more power would it take?

__________________

Necessity may be the mother of Invention but Desperation is quite often the father.

“Sex is like Bridge. If you don't have a good partner, you'd better have a good hand.” - Mae West Papa said, "son there's a lot of evil temptations out there. Best to try 'em all so you know which ones to avoid." |

|

|

|

|

|

#285 | |

|

That Guy

Join Date: Dec 2011

Drives: 2013 asphalt FRS MT

Location: Halifax, Nova Scotia

Posts: 4,865

Thanks: 5,058

Thanked 2,868 Times in 1,499 Posts

Mentioned: 82 Post(s)

Tagged: 1 Thread(s)

|

Quote:

|

|

|

|

|

|

|

#286 | |

|

Senior Member

Join Date: Jan 2012

Drives: '13 GBS Subaru BRZ

Location: Minneapolis, MN

Posts: 2,030

Thanks: 680

Thanked 664 Times in 382 Posts

Mentioned: 26 Post(s)

Tagged: 1 Thread(s)

|

Quote:

I am also considering a larger turbo compressor like a Garret T-76 which will start making good compression around 35K RPM Larger inlet and outlet as well which should help reduce restriction. I'm considering using that for one of my prototypes. It uses a different backplate setup so I'd have to modify my design some.

__________________

-Fortes fortuna adiuvat (Fortune favors the bold)

|

|

|

|

|

|

|

#287 |

|

Senior Member

Join Date: May 2013

Drives: FR-S 10 #103 AT

Location: NC

Posts: 1,519

Thanks: 101

Thanked 599 Times in 347 Posts

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

|

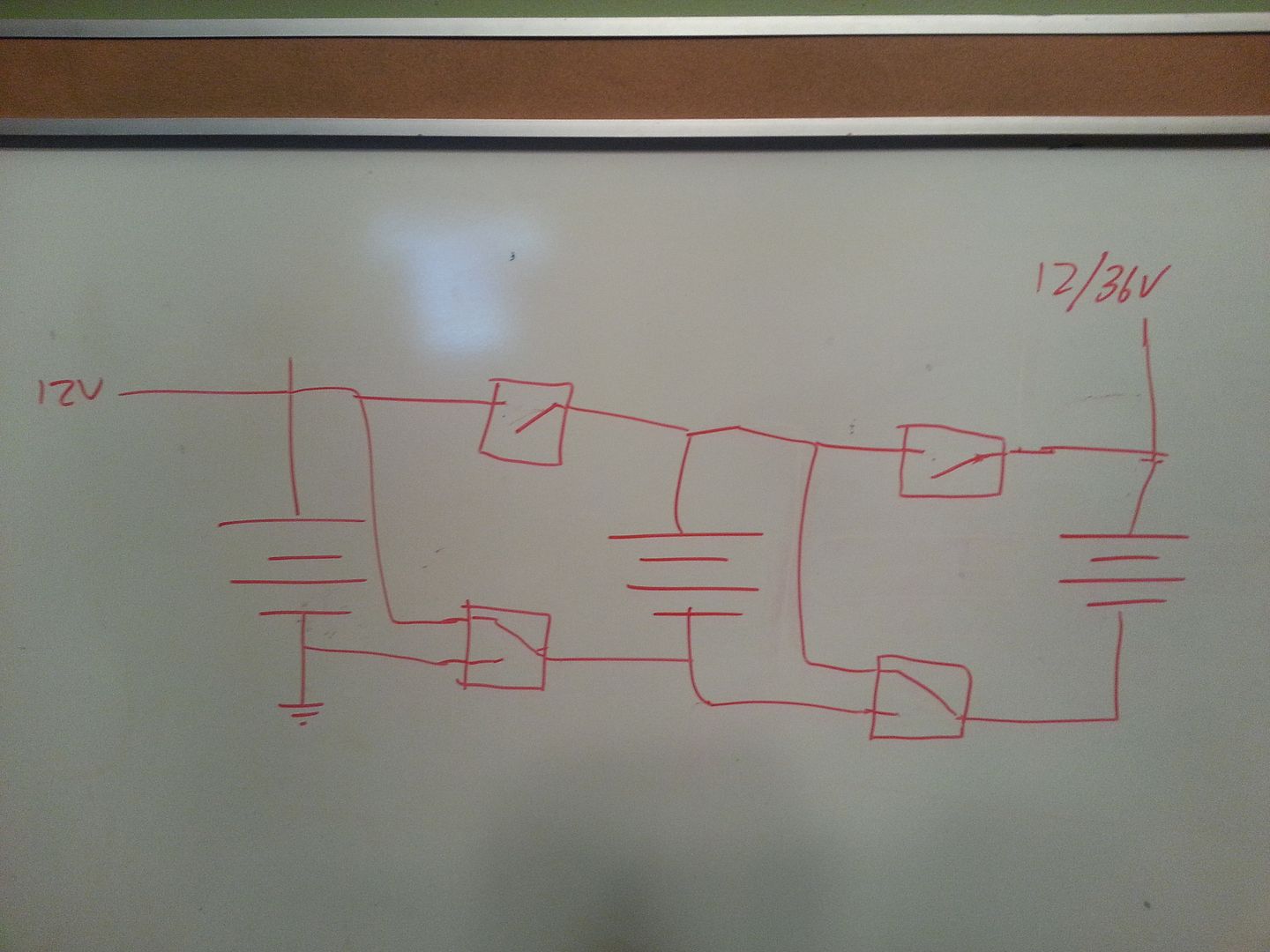

What keeps popping up in my mind when I think of this is a bank of relays wired up so that three identical batteries are wired in parallel and connected to the alternator's charging circuit. When you hit the activation switch, the relays switch and the batteries are in series connected to the electrocharger. You could wire in a voltage sensor that could trip a master relay in the event that one of the other relays ever stuck and the charging system would have seen more than one battery's worth of voltage.

It isn't exactly a new idea but it could work and you don't lose energy converting voltages.

__________________

Necessity may be the mother of Invention but Desperation is quite often the father.

“Sex is like Bridge. If you don't have a good partner, you'd better have a good hand.” - Mae West Papa said, "son there's a lot of evil temptations out there. Best to try 'em all so you know which ones to avoid." |

|

|

|

|

|

#288 | ||

|

Senior Member

Join Date: Jun 2012

Drives: DGM BRZ limited

Location: Indiana

Posts: 366

Thanks: 98

Thanked 147 Times in 95 Posts

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

|

Quote:

More or less I'm not spending too much time on the controller I was speaking of because I'm curious how well the unichip is going to work. Quote:

Obviously this isn't a full plan and would have failsafes/fuses etc, but seems like a solid idea. Ive been doing a bit of looking as far as suitable relays go, but this idea works well for me because I will just put it in the trunk and then it will be perfect for stereo duties as well. If I use some xs power d925's Ill only be adding 20-30 lbs of battery weight but will have significantly more capabilities. |

||

|

|

|

| The Following User Says Thank You to rusty959 For This Useful Post: | DAEMANO (08-23-2013) |

|

|

#290 | |

|

Senior Member

Join Date: Jun 2012

Drives: DGM BRZ limited

Location: Indiana

Posts: 366

Thanks: 98

Thanked 147 Times in 95 Posts

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

|

Quote:

|

|

|

|

|

|

|

#291 |

|

Senior Member

Join Date: Jan 2012

Drives: '13 GBS Subaru BRZ

Location: Minneapolis, MN

Posts: 2,030

Thanks: 680

Thanked 664 Times in 382 Posts

Mentioned: 26 Post(s)

Tagged: 1 Thread(s)

|

Quote:

A few notes on you design: -When the supercharger is in operation I'm pretty sure it will need to be electrically isolated from normal 12v/chassis-ground. -DC solenoid relays of this size (36V / 200 Amp) as far as I can tell only come as single pole. I'll keep looking they may be out there. A different layout could uses lower voltage/current relays which come in STDT versions in parts of the circuit. -Solenoid relays of this size are pretty expensive. So far what I've found start around $80 (x4 = $320) but better deals may be out there. I hope you won't think I'm just criticizing. Overall I like the concept, I was trying to come up with my own but apparently my brain is only good for analyzing other people's designs at the moment.

__________________

-Fortes fortuna adiuvat (Fortune favors the bold)

|

|

|

|

|

|

#292 | |

|

Senior Member

Join Date: Jun 2012

Drives: DGM BRZ limited

Location: Indiana

Posts: 366

Thanks: 98

Thanked 147 Times in 95 Posts

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

|

Quote:

yes, relays and associated cost is an issue, but I feel this is offset by not needing a dedicated charger. The idea im currently looking at is using multiple smaller relays in the 40-50 amp range. Since resistance in the relay should increase with temperature, it should be safe to run a few in parallel. I need to do more research on this. Im spitting off a lot of ideas before I fully think them through, but atleast that allows group thinking. Dont hesitate to criticize, as long as we are being civil it can only help understanding. |

|

|

|

|

|

|

#293 | |

|

Senior Member

Join Date: May 2013

Drives: FR-S 10 #103 AT

Location: NC

Posts: 1,519

Thanks: 101

Thanked 599 Times in 347 Posts

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

|

Quote:

__________________

Necessity may be the mother of Invention but Desperation is quite often the father.

“Sex is like Bridge. If you don't have a good partner, you'd better have a good hand.” - Mae West Papa said, "son there's a lot of evil temptations out there. Best to try 'em all so you know which ones to avoid." |

|

|

|

|

| The Following User Says Thank You to mid_life_crisis For This Useful Post: | DAEMANO (08-23-2013) |

|

|

#294 |

|

Senior Member

Join Date: May 2013

Drives: FR-S 10 #103 AT

Location: NC

Posts: 1,519

Thanks: 101

Thanked 599 Times in 347 Posts

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

|

Did you mean SPDT? His layout works with SPDT. Takes more of them obviously, but it pretty clearly does not require DPDT.

__________________

Necessity may be the mother of Invention but Desperation is quite often the father.

“Sex is like Bridge. If you don't have a good partner, you'd better have a good hand.” - Mae West Papa said, "son there's a lot of evil temptations out there. Best to try 'em all so you know which ones to avoid." |

|

|

|

|

|

|

|

| Tags |

| hairdyerperformance, only pulls hard one gear |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Full throttle Electric Supercharger Build Thread | fenton | Forced Induction | 11315 | 04-07-2025 07:42 PM |

| DUP THREAD MODZ PLZ DELETE KTHX | SloS14 | Forced Induction | 0 | 07-09-2013 06:41 PM |

| Electric Turbocharger | Shankenstein | Forced Induction | 91 | 06-24-2013 03:47 PM |

| Electric 86 | frosty86 | Scion FR-S / Toyota 86 GT86 General Forum | 8 | 11-10-2012 03:16 PM |

| WRX Electric turbo | Neilus | Engine, Exhaust, Transmission | 42 | 05-03-2012 10:20 PM |