|

|

#71 |

|

Member

Join Date: Apr 2016

Drives: Toyota 86 GTS Auto

Location: Australia, Central Coast

Posts: 85

Thanks: 96

Thanked 33 Times in 23 Posts

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

|

As I said I'm no scientist - and I have not looked up the HP(Watts) calculation but it maybe just torque * rpm, because the measurements add up.

The torque is measured in Nm. (i.e. N*m) N itself is kg * m / s^2 (m*a i.e. mass * acceleration) The power is measured in watts (kg*m^2 / s^3 ) I reckon time is a factor even if you think it's not. The measurement itself contains a time element, due to the acceleration being in there, there's no denying it. I think you maybe mixing up a freely rotating body (not driven) with an engine driven system rotating at a constant speed but still requiring power due to the braking effect of all elements in the system - especially on a dyno, since the dyno itself is measuring the torque by resistance (i.e. braking). The other way of thinking about the whole problem; try to rotate a big metal disc by hand, on an axle. Now try to rotate a wooden disc of the same size. It'll be easier. That's the same effect of a lighter pulley in my opinion. And when you try to slow it down, you get hit with a higher force again with the heavier object - it's a kind of an energy storage, the idea that lead to the F1 KERS development (I think). And a final piece of interest: The effect of weight on acceleration is undeniable, and the greater effect of rotational weight is also unquestionable. Here's an interesting piece on wheel weights tested for a more down-to-earth proof of that. I'm not saying a lightweight pulley will give you loots of extra at the wheels, it'd need to be dyno-tested to see how much difference it makes because the car is a big ass complex system. But there's difference, albeit possibly negligible. But hey, it's a fun car either way, and let us all enjoy it.

|

|

|

|

| The Following 2 Users Say Thank You to ysu For This Useful Post: | justatroll (06-20-2016), nikitopo (06-20-2016) |

|

|

#72 | |

|

Senior Member

Join Date: Jun 2013

Drives: 2023 GR SUPRA,15 FR-S (SOLD)

Location: Philadelphia, PA

Posts: 4,234

Thanks: 3,087

Thanked 2,101 Times in 1,397 Posts

Mentioned: 31 Post(s)

Tagged: 2 Thread(s)

|

Quote:

I have an AT as well and was looking into getting one for shits and giggles for the water pump and alternator as well, you really just need a impact or very long breaker bar. It's quite tough and it's honestly not worth it for the gains it supposedly will give.

__________________

*SOLD*OFT Stage 2 UEL E85/Nameless Performance 3 inch axleback with 5 inch mufflers/ TRD CAI / CNT UEL/ Cusco Strut BAR & LHD Brake Stop / "JDM" Toyota Badges / WinJet JDM headlights - DRL MOD from fteightysix.com - 5000K Diode Dynamics HID kit / Diode Dynamics LED interior Lights and sidemarker bulbs / JDM Clear Sidemarkers / Diode Dynamics LED switchbacks/ OLM LED rear turn signals / Tap Turn Relay*SOLD*

|

|

|

|

|

| The Following User Says Thank You to FRSBRZGT86FAN For This Useful Post: | G-awesome (06-20-2016) |

|

|

#73 | |

|

Senior Member

Join Date: Dec 2015

Drives: Full race 4cyl boxer

Location: CO, USA

Posts: 587

Thanks: 310

Thanked 510 Times in 269 Posts

Mentioned: 20 Post(s)

Tagged: 1 Thread(s)

|

Quote:

You are correct that Horsepower has a unit of time in it's representation (sort of). However so does velocity. A feather can be moving at 10 meters per second = 10 m/s A block of lead can be moving at 10 meters per second = 10 m/s Do either of those velocities have anything to do with the mass of the object? No. Velocity (v) is a first order derivative of position: v(t) = change of rate of position with respect to time velocity is in meters per second Acceleration (a) is the second order derivative of position and the first order derivative of velocity a(t) = change of rate of velocity with respect to time (which is the change of rate of 'position with respect to time' with respect to time) acceleration is in meters per second per second. THIS is where the mass of the object comes into play. In measuring the horsepower of an engine, the calculation is made at static (constant velocity - non accelerating) conditions. Therefore the resistance to acceleration (mass) is not a factor. If you wanted to measure how fast the engine can rev from one RPM to another RPM then you need the horsepower AND the rotational mass to calculate the acceleration of the engine. But again, horsepower is NOT a direct measure of how quickly the engine can accelerate. We are fooled into thinking the horsepower has something to do with how quickly we can ramp the dyno but it does not. Think of it another way: will you get different hp readings by being in different gears during the pull? Fundamentally NO. The people who know the details will answer with 'yes' but that has to do with different losses in the transmission based on friction differences between different gears. I am not trying to say that the lighter weight pulley will not make any difference in the acceleration of the engine by itself or the acceleration of the entire system. My biggest two arguments are: 1 - A lighter rotating mass cannot make a difference in Horsepower measurements and 2 - A lighter weight crank pulley CAN make a difference in vehicle acceleration but the difference between removing the weight from the pulley and removing the weight from anywhere else on the car is imperceptible to a human Almost all of this argument comes from people making the two false statements: "My LWCP makes 5 more hp" - no it doesnt and "I can feel the difference in acceleration with my LWCP" - no you cant. Now my statement above "1 - A lighter rotating mass cannot make a difference in Horsepower measurements" Is where a lot of contention comes from. CLEARLY if I put a big ass unbalanced weight on the engine then you WILL measure a difference in horsepower output because the engine cannot deliver peak horsepower to the output shaft when it is out of balance. This is because the parasitic losses are greater as the friction coefficient is dynamic. So proper balance (and reduction of harmonics) CAN show up as a difference in HP output. THAT is why the fluiddamper pulley produced MORE apparent HP even though it is heavier than the other two pulleys tested. Last edited by justatroll; 06-20-2016 at 04:23 PM. |

|

|

|

|

|

|

#74 | |

|

Senior Member

Join Date: Dec 2015

Drives: Full race 4cyl boxer

Location: CO, USA

Posts: 587

Thanks: 310

Thanked 510 Times in 269 Posts

Mentioned: 20 Post(s)

Tagged: 1 Thread(s)

|

Quote:

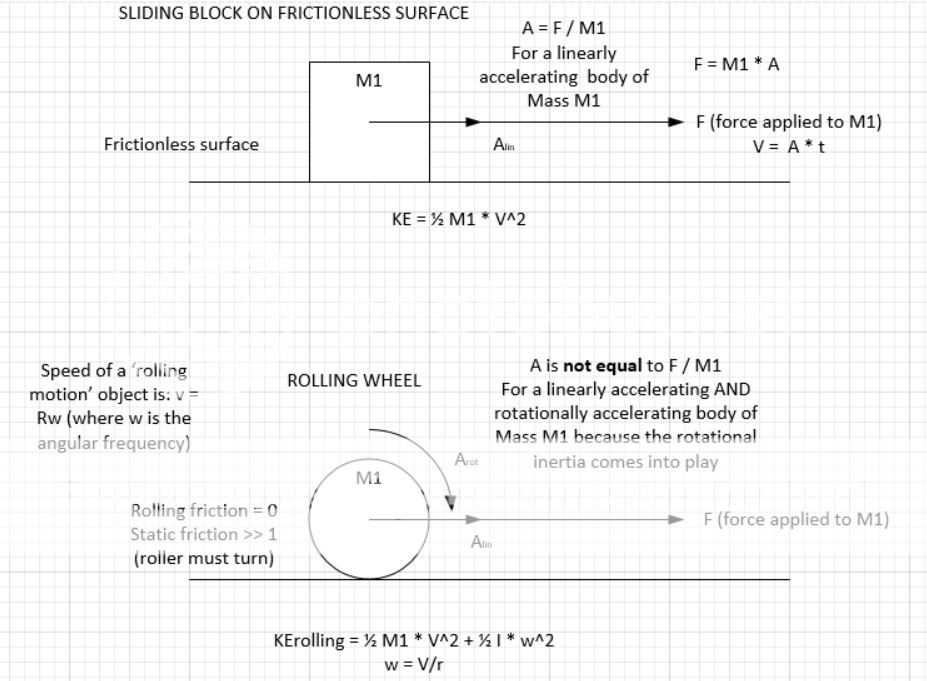

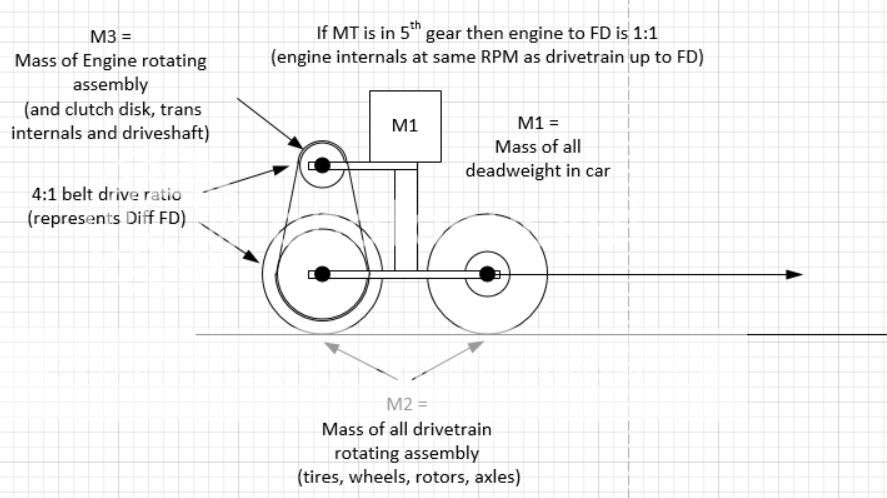

@nova.86 Here are some diagrams and problems to work with in your Mechanics class (assuming it is dynamics and not just statics). The first diagram shows the #1 most basic diagram of a mass sliding on a frictionless surface. Just about anyone has seen that one. The second diagram is actually more complicated than most can do the calculations for but is still considered basic. It shows a mass to be accelerated, BUT since it must roll to accelerate it has a component of rotational inertia that must be compensated for to know velocity based on applied force:  The 'R' is the radius of the wheel This diagram is incomplete but shows a simple model of a vehicle system. Once I get it done, we can plug in actual numbers for vehicle mass and rotational mass to determine how big a factor small changes in rotational mass has on the overall system:  I have also started trying to model all of the key rotational objects in our cars in Solidworks (I start with Onshape because it is free) but that will take me a long time to build a model worthy of discussion. People who actually operate chassis dynos on our cars probably know a value we can use for total system rotational inertia as the dyno provides a calculated value following the pulls. |

|

|

|

|

| The Following User Says Thank You to justatroll For This Useful Post: | nova.86 (06-20-2016) |

|

|

#75 |

|

Senior Member

Join Date: Mar 2014

Drives: '15 BRZ RA

Location: Greece

Posts: 3,787

Thanks: 2,417

Thanked 1,947 Times in 1,263 Posts

Mentioned: 29 Post(s)

Tagged: 0 Thread(s)

|

|

|

|

|

|

|

#76 |

|

Senior Member

Join Date: May 2013

Drives: 2013 FR-S, white, MT

Location: Puyallup, WA

Posts: 30,432

Thanks: 29,826

Thanked 32,845 Times in 16,844 Posts

Mentioned: 715 Post(s)

Tagged: 2 Thread(s)

|

Well, folks, I've pretty much stayed out of this debate because I don't have any first hand experience with a lighter crank pulley and it appears that any data is difficult to verify.

However, my 73 year old ex-farm boy eyes looks at this engine and visualizing all the driven parts (drivetrain), and find it hard to believe that a four pound difference in that center pulley, is going to make any significant difference in anything ........  humfrz |

|

|

|

| The Following 3 Users Say Thank You to humfrz For This Useful Post: |

|

|

#77 | |

|

Legendary Member

Join Date: Aug 2015

Drives: HyperBlue BRZ

Location: Oxnard, CA

Posts: 365

Thanks: 138

Thanked 180 Times in 90 Posts

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

|

Quote:

"For Engineering and Physical Science students. Statics/dynamics of particles and rigid bodies. Newton's Laws of Motion, conservation principles, rotational motion, simple harmonic motion, wave motion and sound." Then Spring I got Heat, Light, Optics, Modern Physics " Mechanical waves, thermodynamic processes and systems, kinetic theory, light and modern physics." and Next year Fall , Electricity & Magnetism "Electrostatics, DC circuits, magnetism and electromagnetism, alternating current theory, electromagnetic radiation and electromagnetic waves." Lol, and then a whole spring dedicated to Modern Physics, it's gonna be fun though. Can't wait to take Differential equations next year and apply them.

__________________

|

|

|

|

|

|

|

#79 | |

|

Senior Member

Join Date: Dec 2015

Drives: Full race 4cyl boxer

Location: CO, USA

Posts: 587

Thanks: 310

Thanked 510 Times in 269 Posts

Mentioned: 20 Post(s)

Tagged: 1 Thread(s)

|

Quote:

[IMG]http://strictlyperformance.parts/shop/media/catalog/product/cache/1/image/2e88***8f4d9dbb86a2e5c710924e918/c/3/c35483eb-105b-4e5b-bfc5-e184617cb459.jpg[/IMG] Or the cams:  Or the internals:   And the flywheel:  I have been wanting to build up a model of the whole rotating assembly but even finding shipping weights for things like cranks & clutches takes some effort |

|

|

|

|

|

|

#80 | |||||||||

|

Member

Join Date: Apr 2016

Drives: Toyota 86 GTS Auto

Location: Australia, Central Coast

Posts: 85

Thanks: 96

Thanked 33 Times in 23 Posts

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

|

Quote:

So when you're measuring torque, you do measure something with an acceleration factor. As I said earlier, I think you're mistaking an un-driven rotating wheel without resistance with one that's driven and being slowed (at the same time - hence it needs force to keep rotating at the same speed) Of the freely rotating wheel you can measure the speed (it's constant) but not torque - there is no torque until you start acting some force on it (accelerate/decelerate). Quote:

And in this case the distance is from the rotational center - (to explain this with a simple example, try to stop a 10kg disc with all the weight on the outside, say 1m away from the axle, compared to a small 10kg rotating rod, that's how the distance here works, and that's why big ass tyres are not a very good idea on a low-powered car - they have a lot of weight farther from the centerpoint) Quote:

Quote:

Quote:

Quote:

5hp? god knows. Needs to be measured. Quote:

Quote:

Quote:

We seem to be going astray here. Sorry I need to work, so I'll stop here. The difference is there I reckon, if I look at the calculations it's pretty darn clear. But the amount of difference maybe imperceptible / impractical. We won't know until someone dynos it. Thanks for your response, but I won't repeat myself again, once was enough, no disrespect. You seem to be stuck in a never-ending circle thinking of something else when you talk about torque (and power) to me. Sometimes you say acceleration only, sometimes an un-driven freely spinning wheel without forces acting on it, neither are entirely correct. Hell you've even missed the time element early on. I understand that you're looking for a physicist to explain it to you, I'm not a scientist as I said, and very much not a teacher, and I think that's who you'd need to get this explained properly. This is as far as I can go

|

|||||||||

|

|

|

| The Following 3 Users Say Thank You to ysu For This Useful Post: |

|

|

#81 |

|

Not a troll

Join Date: Apr 2015

Drives: FR-S

Location: Canada

Posts: 5,104

Thanks: 8,237

Thanked 5,399 Times in 2,694 Posts

Mentioned: 266 Post(s)

Tagged: 4 Thread(s)

|

@ysu, thank you for putting in some real thought to the debate here.

While I still believe that it doesn't make any difference, going off of data I've seen before, and I'm inclined to agree with @justatroll, you're right though, I don't think you could perceive the difference if there was one. Not here to stir the pot, because this massive knowledge bomb is great to read. However, it does seem that as a whole system, a LWCP does not do anything. As a single piece, maybe, but that isn't the case here. And I'll say it again (at least I think I am), if you want to do the LWCP, then by all means, I'm not here to dissuade you, I don't think it's going to be catastrophic for your engine. But for myself, I'd rather not risk it. much the same as FI for me. Plenty of people running boost without issue, but, for me, not worth the risk. |

|

|

|

| The Following User Says Thank You to Cole For This Useful Post: | justatroll (06-20-2016) |

|

|

#82 | |

|

Senior Member

Join Date: Dec 2015

Drives: Full race 4cyl boxer

Location: CO, USA

Posts: 587

Thanks: 310

Thanked 510 Times in 269 Posts

Mentioned: 20 Post(s)

Tagged: 1 Thread(s)

|

Quote:

A Torque is a STATIC value of the force applied multiplied by the length of 'moment arm'. Your torque wrench measures just fine with it not moving, in fact that is the only time it measures accurately. It has absolutely nothing to do with acceleration. I can apply a torque to something with a tiny rotational inertia and have it move a lot. I can apply the same torque to something with a huge rotational inertia and have it move very little. The rotational inertia of the system in no way affects the torque applied to it. The response of the system to that torque IS affected by the rotational inertia. I will attempt to address the other points below as well. |

|

|

|

|

| The Following User Says Thank You to justatroll For This Useful Post: | Cole (06-20-2016) |

|

|

#83 | |

|

Senior Member

Join Date: Dec 2015

Drives: Full race 4cyl boxer

Location: CO, USA

Posts: 587

Thanks: 310

Thanked 510 Times in 269 Posts

Mentioned: 20 Post(s)

Tagged: 1 Thread(s)

|

Quote:

Above, I believe you are talking about using an inertia dyno to determine the HP of a 'powerplant' (engine or chassis dyno). In this case the machine measures the acceleration of the system to determine the output of the powerplant. So they are using the known characteristics of their dyno (the rotational inertia) and essentially a stop watch the measure the amount of time it takes the poweplant (outputting on unknon torque) to accelerate their known inertial mass. They then calculate the torque required over the measured time to obtain the RPM of the inertial mass. In fact to calibrate these inertial masses all you need is a small known force over a very small rotation and observe the motion. They do this to determine the average torque applied over the duration of the 'run' (and therefore the HP) of the power plant. New variable load dynos can apply enough of a "brake" to keep the engine from being able to increase RPM while the torque applied to the brake is measured at a constant RPM. The data acquisition system is just so fast that the system does not need to "pause" noticeably at each sample point. |

|

|

|

|

| The Following User Says Thank You to justatroll For This Useful Post: | Cole (06-20-2016) |

|

|

#84 | |

|

Senior Member

Join Date: Dec 2015

Drives: Full race 4cyl boxer

Location: CO, USA

Posts: 587

Thanks: 310

Thanked 510 Times in 269 Posts

Mentioned: 20 Post(s)

Tagged: 1 Thread(s)

|

Quote:

Removing mass from the pulley WILL reduce the 'inertia' of the system (resistance to acceleration). Some of the inertia that is reduced is in the overall rotational inertia of the rotating assembly (a VERY SMALL percentage of total of the rotating assembly) Another piece of the inertia that is reduced is because you removed weight from the car as a whole. That second piece of the overall car's inertia is a far larger percentage than the rotational piece. So it does not "result in extra power at the wheels". It results in "less total mass" and with the exact same power at the wheels, will accelerate faster. |

|

|

|

|

|

|

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Perrin crank pulley / Beatrush alternator pulley | Krimlin | Engine, Exhaust, Bolt-Ons | 7 | 08-26-2013 11:12 AM |

| FS:PERRIN Light weight pulley NEW $85 Shipped | Amalgamo | Engine, Exhaust, Bolt-Ons | 1 | 05-01-2013 12:10 PM |

| FS: BNIB Perrin Light Weight Crank Pulley | jflogerzi | Engine, Exhaust, Bolt-Ons | 3 | 03-31-2013 02:06 AM |