|

||||||

| Suspension | Chassis | Brakes -- Sponsored by 949 Racing Relating to suspension, chassis, and brakes. Sponsored by 949 Racing. |

|

|

|

Thread Tools | Search this Thread |

|

|

#211 | |

|

The SquadWhisperer

Join Date: Mar 2013

Drives: '13 Ultramarine FR-S (STX)

Location: Nova Scotia, Canada

Posts: 681

Thanks: 383

Thanked 477 Times in 207 Posts

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

|

Quote:

Actually many of them do give a rough value for camber. Especially in competition oriented tires.

__________________

2013+14+15 Atlantic Region Motor Sports Autocross STX Champion

2013+14+15 Atlantic Region Motor Sports Overall Autocross Champion 2017 Bluenose Autosport Club Overall Rallycross Champion Powered by Great North Performance, Jani-King Canada, and OK Tire. |

|

|

|

|

|

|

#212 | |

|

Senior Member

Join Date: Nov 2014

Drives: 2015 Scion FR-S 6MT

Location: Dallas, TX

Posts: 370

Thanks: 152

Thanked 166 Times in 114 Posts

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

|

Quote:

__________________

|

|

|

|

|

|

|

#213 |

|

Senior Member

Join Date: Aug 2013

Drives: BRZ

Location: Denver, CO

Posts: 845

Thanks: 677

Thanked 397 Times in 264 Posts

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

|

Yea youre right, it just depends on the series. IRL actually supplied the tire data. Brazilian stock car didnt allow testing. V8 Supercar made you test your own tires. All different.

|

|

|

|

|

|

#214 |

|

Frosty Carrot

Join Date: Jan 2013

Drives: The Atomic Carrot

Location: Baltimore, MD

Posts: 513

Thanks: 272

Thanked 431 Times in 199 Posts

Mentioned: 19 Post(s)

Tagged: 0 Thread(s)

|

@RBbugBITme ,

Thanks for helping out the thread with your mad WinGeo skills. I've added your Caster, Roll Center, and Motion Ratio data to the OP. If we can support your efforts/project, don't hesitate to ask. I was curious about how you pulled the points for your model. It sounds pretty precise. Is the Toyota 3D model an assembly file or one giant file? What kind of access are you given? For my current employer, the OEMs are pretty forward with the level of detail in their models (once you sign the NDA)... but it's usually just assemblies of STEP files (dumb solids). We use them to check clearances, mounting locations, air/water paths, etc. I was curious the level of play that Toyota is giving the aftermarket and enthusiast community. If you can't say, that's OK too. It's great to have another suspension modeling guy on the 86 forums.

__________________

If you think you're nerd enough, join in the discussions about Suspension and Aerodynamic modelling!

Wall of Fame - JDL Auto Design, Raceseng, Vishnu Tuning, Penske Shocks, Nameless, Perrin, RaceComp Engineering, Essex/AP Racing, Verus, RacerX Wall of Shame - aFe Takeda, Wilwood, FA20Club |

|

|

|

|

|

#215 | ||

|

Senior Member

Join Date: Jun 2014

Drives: S60R/Corvette

Location: Reading, PA

Posts: 104

Thanks: 4

Thanked 236 Times in 59 Posts

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

|

Quote:

Quote:

I'm also provided with assemblies of just the suspension in 3 different positions. I wasn't quite sure what this was but I found it the middle position was ride height and the other two were *designed* full droop/compression.

__________________

Ryan M.

Strange Engineering Director of Suspension Development |

||

|

|

|

| The Following 2 Users Say Thank You to RBbugBITme For This Useful Post: | Calum (02-26-2015), Shankenstein (02-26-2015) |

|

|

#216 |

|

Senior Member

Join Date: Jun 2014

Drives: S60R/Corvette

Location: Reading, PA

Posts: 104

Thanks: 4

Thanked 236 Times in 59 Posts

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

|

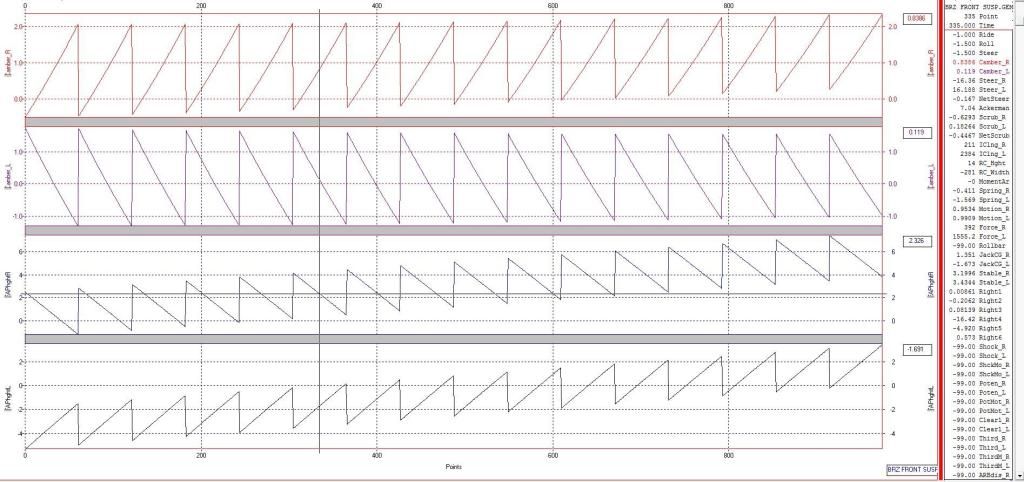

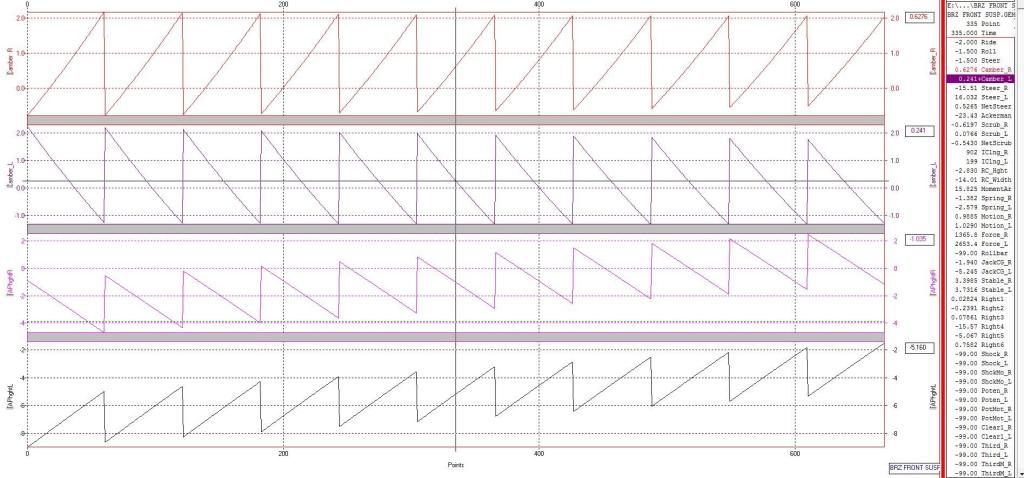

Alright, here are the camber curves and FAP's at two different ride heights.

What I've done is select a static steer angle to account for the effect of caster, and then iterated chassis roll angle from -3 degrees to 0 degrees, and ride height from -1.5" to 0" in the first one and -2.5" to 1.5" in the second image. In other words, this is a right hand turn with variable chassis roll and variable ride height with the same steer angle which would mean we're looking at the same steering wheel input at varying track speeds (chassis roll angle varies with speed/G's acting on your FAP's/RC/moment arm). The solid black vertical line in both images is at -1.5 degrees of chassis roll at -1" and -2" ride height. CamberL is the outside front tire which is the most heavily loaded tire in this scenario. Each sawtooth section is the change in ride height by .100" and ride height is increasing from left to right. Left most sawtooth section is -1.5" ride height with roll angle varying from -3 deg to 0 deg. Right most saw tooth is OEM ride height.  Same thing as above but the left most sawtooth is at -2.5" ride height with roll angle varying from -3 deg to 0 deg. Right most sawtooth is -1.5" ride height.

__________________

Ryan M.

Strange Engineering Director of Suspension Development |

|

|

|

|

|

#217 |

|

Senior Member

Join Date: May 2011

Drives: '23 BRZ

Location: Providence, RI

Posts: 4,672

Thanks: 1,439

Thanked 4,011 Times in 2,097 Posts

Mentioned: 85 Post(s)

Tagged: 0 Thread(s)

|

The problem I have is with the RC height curve shown here (with context):

Quote:

1. At -1.05" ride height, roll center starts at zero (ground level) at zero roll, and rapidly goes CRAZY HIGH (way above ground) with any roll in either direction. 2. At -0.95" ride height, roll center starts at zero (ground level) at zero roll and rapidly goes CRAZY NEGATIVE (way below ground) with any roll in either direction. Even with perfectly rigid spherical bearings all around, no way that's what happens. Such a car would exhibit zero roll in cornering at -1.05" ride height, but would immediately flop all the way to the bump stops in corners at -0.95" ride height. I still strongly believe the math model is breaking down with roll applied when static RC height is at ground level and giving unrealistic RC height change with roll. The roll center height calculation is based on an intersection point of a line that is tending out towards infinity. In that region, you get to a point where you can't calculate RC height with enough precision to give reasonable results. You can run the numbers and get results, but when basing RC height which is on the order of inches on a line that's going out billions of miles and beyond, the calculated RC height value becomes kinda meaningless... I would bet that a physics-based vehicle simulation model would give different results, and I'm *certain* that an actual FR-S/BRZ won't behave like it had infinite roll stiffness at -1.05" ride height and zero roll stiffness at -0.95" ride height even with spherical bearings all around. Last edited by ZDan; 02-26-2015 at 09:49 AM. |

|

|

|

| The Following User Says Thank You to ZDan For This Useful Post: | fika84 (02-26-2015) |

|

|

#218 | |

|

Senior Member

Join Date: Aug 2013

Drives: BRZ

Location: Denver, CO

Posts: 845

Thanks: 677

Thanked 397 Times in 264 Posts

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

|

Quote:

. These are limitations to the geometric method. That's why I would like to see a force based simulation, or track data with wheel force transducers (at $50k/wheel I don't think anyone has this...) so that I could calculate the force based RC myself. Or as @Amaya was hinting at (even though he didn't know it..) was skid pad data. They don't put rigid suspension in for this since they want the car to behave as it's supposed to.. the hardest part about skid pad testing is getting a driver to be able to maintain constant lateral g (and you need lots of sensors). They DO however put solid suspension rods in when doing K&C testing (which can also give you force based roll centers!), which is an entirely other animal used to test the compliance in a vehicle (how much does it move when forced through metal bending and bushings compressing). . These are limitations to the geometric method. That's why I would like to see a force based simulation, or track data with wheel force transducers (at $50k/wheel I don't think anyone has this...) so that I could calculate the force based RC myself. Or as @Amaya was hinting at (even though he didn't know it..) was skid pad data. They don't put rigid suspension in for this since they want the car to behave as it's supposed to.. the hardest part about skid pad testing is getting a driver to be able to maintain constant lateral g (and you need lots of sensors). They DO however put solid suspension rods in when doing K&C testing (which can also give you force based roll centers!), which is an entirely other animal used to test the compliance in a vehicle (how much does it move when forced through metal bending and bushings compressing). The geometric RC has some merit (it's better than nothing and is typically all that is used for FSAE teams to design a little racecar) and is much easier to attain, but it doesn't tell the entire story and it's important to understand where it does and doesn't work (like all simulation analysis). |

|

|

|

|

| The Following User Says Thank You to fika84 For This Useful Post: | ZDan (02-26-2015) |

|

|

#219 |

|

Senior Member

Join Date: Jun 2014

Drives: S60R/Corvette

Location: Reading, PA

Posts: 104

Thanks: 4

Thanked 236 Times in 59 Posts

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

|

ZDan, I understand any RC related equations become useless when it is very near the ground plane. That doesn't change the fact that when it (or the FAP if you prefer) passes back and forth above and below the ground plane your jacking forces will be constantly reversing direction. That isn't going to be good for stability at the limit of tire adhesion unless you have minuscule jacking forces to begin with. I don't know what typical jacking forces are for this car.

__________________

Ryan M.

Strange Engineering Director of Suspension Development |

|

|

|

|

|

#220 | ||

|

Senior Member

Join Date: May 2011

Drives: '23 BRZ

Location: Providence, RI

Posts: 4,672

Thanks: 1,439

Thanked 4,011 Times in 2,097 Posts

Mentioned: 85 Post(s)

Tagged: 0 Thread(s)

|

Quote:

Quote:

The fact that it goes from slightly anti-roll to slightly pro-roll is not in itself a huge deal. It's not like the forces go crazy near zero. |

||

|

|

|

|

|

#221 | |

|

Senior Member

Join Date: Jun 2014

Drives: S60R/Corvette

Location: Reading, PA

Posts: 104

Thanks: 4

Thanked 236 Times in 59 Posts

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

|

Quote:

__________________

Ryan M.

Strange Engineering Director of Suspension Development Last edited by RBbugBITme; 02-26-2015 at 01:04 PM. |

|

|

|

|

|

|

#222 |

|

Senior Member

Join Date: May 2012

Drives: '13 BRZ Ltd

Location: PA

Posts: 458

Thanks: 265

Thanked 230 Times in 117 Posts

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

|

Quote:

Thanks for posting and doing all of the work. I haven't looked at this thread in a while... time to read up. |

|

|

|

|

|

#223 |

|

First a good link on FAPs (Force Application Points) vs. Kinematic roll centers that might help everyone that's interested in this discussion:

https://drive.google.com/file/d/0B3p...ew?usp=sharing It's worth reading...and rereading a couple more times. - Andy |

|

|

|

|

| The Following 3 Users Say Thank You to Racecomp Engineering For This Useful Post: |

|

|

#224 | |

|

Second, a quote from a discussion I had with Bryan at JRZ USA a while ago:

Quote:

|

||

|

|

|

|

|

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| New Rumor: Subaru Developing Turbo 4 2.0T for BRZ | Hachiroku | BRZ First-Gen (2012+) — General Topics | 350 | 02-02-2013 02:52 PM |

| Need opinions on two new items we're developing! | yospeed | Cosmetic Modification (Interior/Exterior/Lighting) | 56 | 12-03-2012 03:13 AM |

| Chances of Someone Developing 5x114.3 HUBS (not spacers)? | Entropy | Wheels | Tires | Spacers | Hub -- Sponsored by The Tire Rack | 9 | 08-04-2012 04:35 PM |

| Hi-res pics & list of BRZ JDM model grades from stripped down base model to STI(?) | switchlanez | BRZ First-Gen (2012+) — General Topics | 68 | 02-14-2012 08:16 AM |