|

|

#127 |

|

Senior Member

Join Date: Mar 2011

Drives: '06 AM V8V Coupe

Location: United States of America

Posts: 5,279

Thanks: 285

Thanked 1,074 Times in 759 Posts

Mentioned: 13 Post(s)

Tagged: 1 Thread(s)

|

I think by "not as strong" he isn't actually saying it's less strong, but when the rotational speed is slower the bearing is under high stress for longer periods at a time and it gives the oil more time to be "squeezed" out. Or at least that's how I am understanding it.

At high rpm the forces on the bearings are greater but the oil film is being compressed for a smaller amount of time each cycle so the film can be maintained more easily. In my head this is the picture: You have say 2 pieces of glass with water between, if you squeeze really hard and hold, the water will come out the edges and drip off. If you squeeze hard only momentarily the water doesn't have time to be displaced as much, so even if you are spending the same total amount of timing squeezing, if you "give it a rest" then the water will stay. |

|

|

|

|

|

#128 | |

|

GL 86!

Join Date: Mar 2011

Drives: Maybe FR-S... maybe not

Location: NA

Posts: 356

Thanks: 0

Thanked 0 Times in 0 Posts

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

|

Quote:

Hence I am wondering at what oil pressure is the hydrodynamic wedge broken? It has to due with the oil, oil pressure, and the forces exerted on the journals and bearings. Lack of centrifugal speed/time isn't as much of a concern as low oil pressure in this case. |

|

|

|

|

|

|

#129 |

|

Senior Member

Join Date: Mar 2011

Drives: '06 AM V8V Coupe

Location: United States of America

Posts: 5,279

Thanks: 285

Thanked 1,074 Times in 759 Posts

Mentioned: 13 Post(s)

Tagged: 1 Thread(s)

|

Is oil pressure measured at the oil pump?

If it is the oil pressure is more of an indication of flow. Bearings aren't sealed I think so oil pressure probably doesn't have to do with that. I read on bobistheoilguy that the oil pressure being high when the engine is cold means the oil is actually not flowing enough and hence the engine experiences the greatest wear. The hydrodynamic film is held by surface tension or whatever it's called lol. Oil sticking to the surface of the metal. Don't remember what that's called. |

|

|

|

|

|

#130 | |

|

GL 86!

Join Date: Mar 2011

Drives: Maybe FR-S... maybe not

Location: NA

Posts: 356

Thanks: 0

Thanked 0 Times in 0 Posts

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

|

Quote:

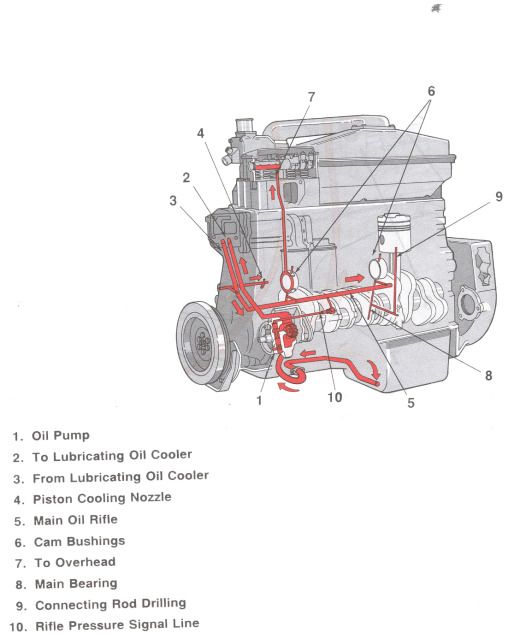

This is from the Cummins Manual, it shows the oil circuit of the engine. I hope this explains a bit because until I actually rebuilt an engine I had no idea what the oil circuit looked like or how oil got where...  Actually that definition is partially correct. The engine experiences bearing wear because while the engine is not rotating (stopped) there is little oil between the bearing and journal. Why? No oil pressure! If the engine oil is not flowing enough after cold engine start up then someones made an error with the oil viscosity or the oil pump is kaputski (among other mishaps). It should reach an acceptable hydrodynamic film pretty much right after start. The oil should be flowing because the oil pump is positive displacement (typically a simple gear type), if not, the oil is extremely cold/wrong viscosity for conditions. Sorry for going Way OT Last edited by Exage; 02-08-2012 at 09:30 PM. |

|

|

|

|

|

|

#131 |

|

Senior Member

Join Date: Mar 2011

Drives: '06 AM V8V Coupe

Location: United States of America

Posts: 5,279

Thanks: 285

Thanked 1,074 Times in 759 Posts

Mentioned: 13 Post(s)

Tagged: 1 Thread(s)

|

On bobistheoilguy it said that ALL oils are too thick at startup, the thinnest synthetic bases are like 70cS at room temperature or something, while at operating temperature it goes down to single digits cS (the correct viscosity), which is why you don't rev a cold engine, because the cold oil doesn't flow well. Since the oil pump is positive displacement I take this to mean that the oil doesn't penetrate the bearings or something like that.

Thanks for the picture though. EDIT: Oh HomemadeWRX I just noticed your comment...gee don't even get me started on that, I'm in math for god's sake :P old greg if it seems like I think I know everything, sorry for being such an eyesore. Last edited by serialk11r; 02-09-2012 at 12:36 AM. |

|

|

|

|

|

#132 |

|

Rocket Surgeon

Join Date: Apr 2011

Drives: PSM GGA OMG

Location: FL

Posts: 1,312

Thanks: 10

Thanked 141 Times in 84 Posts

Mentioned: 2 Post(s)

Tagged: 1 Thread(s)

|

It was meant lightheartedly. :happy0180:

You're obviously a very bright guy, you just have the confidence of youth.  Well, since you asked nicely...  Honestly, I'm really not an engine guy. Most of the stuff you guys talk about in that area goes right over my head, but I do know a bit about bearings. Main and rod bearings are hydrodynamic bearings, they operate due to relative motion, not oil pressure. Oil pressure is required only because, as you mentioned earlier, the bearings are not sealed. The basic theory is that when the crank is not quite concentric with the bearing (due to load) the relative motion between the crank and bearings is trying to drag the oil through too small a gap for it all to fit. This creates a pressure differential and a force that counteracts the load without the crankshaft actually touching the bearings. The closer the crank gets to the bearing (higher load) the more force is generated, and the higher the speed the more force is generated for a given crank/bearing gap. Lugging occurs when the load on the crankshaft (from cylinder pressure) is high enough that oil alone can not provide an equal reaction force and the crankshaft contacts the bearings. It happens because there is not enough relative motion to support the load, rather than not enough oil pressure. Last edited by old greg; 02-09-2012 at 02:18 AM. |

|

|

|

|

|

#133 |

|

Senior Member

Join Date: Mar 2011

Drives: '06 AM V8V Coupe

Location: United States of America

Posts: 5,279

Thanks: 285

Thanked 1,074 Times in 759 Posts

Mentioned: 13 Post(s)

Tagged: 1 Thread(s)

|

hahaha thanks...

That makes sense. I read somewhere that if you're in high gear going up a steep slope and you're flooring it but the engine is decelerating anyways that's called "lugging". But the forces on the the bearings wouldn't change so this shouldn't damage the engine right? |

|

|

|

|

|

#134 | |

|

MODERATOR-SAMA

Join Date: Oct 2009

Drives: Swagtron Scooter

Location: Seattle

Posts: 2,685

Thanks: 345

Thanked 1,562 Times in 524 Posts

Mentioned: 81 Post(s)

Tagged: 0 Thread(s)

|

Quote:

You know i was looking at some different brands for headers and dyno runs on legacy and 2.5rs. So far i really don't see that big of a dip for TWE, OBX and Cobb headers. they look smoothened out, at the very least. I still see hints of that dip, and im looking at other threads with AFR readings and it gets pretty rich around 3-4k for the N/A motors. Lots of people have better looking curves with that ranged leaned out. But borla and some other knock offs with the same sort of collector design still show that dip regardless of increased in power.

__________________

|

|

|

|

|

|

|

#135 | |

|

Pro Subie Engine Nerd

Join Date: Dec 2011

Drives: BRZ has a reserved space

Location: 3MI Racing LLC

Posts: 261

Thanks: 0

Thanked 1 Time in 1 Post

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

|

Quote:

|

|

|

|

|

|

|

#136 |

|

Rocket Surgeon

Join Date: Apr 2011

Drives: PSM GGA OMG

Location: FL

Posts: 1,312

Thanks: 10

Thanked 141 Times in 84 Posts

Mentioned: 2 Post(s)

Tagged: 1 Thread(s)

|

|

|

|

|

|

|

#137 |

|

Wiring Nerd

Join Date: Nov 2011

Drives: 1994 Supra

Location: Wake County NC

Posts: 455

Thanks: 17

Thanked 19 Times in 12 Posts

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

|

Think of it like riding on skis. If you slow down too much you'll start to sink.

|

|

|

|

|

|

#138 |

|

Re-member

Join Date: Nov 2011

Drives: Toyota camry

Location: S. Cali

Posts: 1,001

Thanks: 98

Thanked 292 Times in 152 Posts

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

|

Ok, for all you smarty pants, if torque is what moves you and is also what you ''feel'' why do F1 cars have basically no torque and super high Hp? I still argue that, in the end, HP is more important. That's why we see power to weight, not torque to weight metrics.

__________________

Nothing decays like progress, and nothing preserves like neglect.

|

|

|

|

|

|

#139 | |

|

86 Member

Join Date: Dec 2010

Drives: 2013 Toyota 86 2.0T (Asphalt)

Location: Atlanta, Ga

Posts: 3,129

Thanks: 126

Thanked 527 Times in 296 Posts

Mentioned: 2 Post(s)

Tagged: 2 Thread(s)

|

Quote:

|

|

|

|

|

|

|

#140 | |

|

GL 86!

Join Date: Mar 2011

Drives: Maybe FR-S... maybe not

Location: NA

Posts: 356

Thanks: 0

Thanked 0 Times in 0 Posts

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

|

Quote:

Power = Force X Distance / Time HP is roughly calculated with: Torque x Rpm / 5252 5252 is some conversion factor I don't have the heart to research right now. Speed of the engine torque is applied at gives you the amount of power the engine is producing at RPM. Something like 10m (~33ft) cable with a 10kg (~22lbs) weight attached, and you have a spool/drum to do a vertical lift. I'm in metric sorry for those who use the imperial. The force is 10kg x 9.81m/s2 (gravity), distance 10m. Two electric motors lift the weight up vertically. One motor takes 20 seconds the other 30 seconds. They didn't do the same work despite delivering the same force: (98.1N X 10m / 20s) = 49.1W : In 1 minute this motor can lift 10kg 3 times. (98.1N X 10m / 30s) = 32.7W: In 1 minute this motor can lift 10kg twice. Also the RPM of the spool will be different: I'm sure you can figure out which is faster. It's hard to explain, I hoped going liner (strait line) helped. ____________ People try to keep RPM low. Fuel economy, engine wear, noise etc... The way to counter lack of power at daily driving speeds is an increase in torque. This is achieved through drive-train design. Hence when SUB says his RSX is gutless because it has little torque, what he means is it develops insufficient power for his liking at low rpm (or the whole range)   . .

|

|

|

|

|

|

|

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| 2013 Porsche Boxer is revealed early | DIG1992 | Other Vehicles & General Automotive Discussions | 62 | 09-05-2012 01:26 PM |

| Next Gen Boxer Engine 4U-GSE | WingsofWar | Engine, Exhaust, Transmission | 33 | 12-10-2011 01:04 AM |

| Toyota Reconfirms Production 2012 FR-S / FT-86 Boxer Engine, 6MT, 6AT, LSD | Hachiroku | Scion FR-S / Toyota 86 GT86 General Forum | 30 | 05-02-2011 04:30 AM |

| Could this be the base FT-86 boxer engine? | iff2mastamatt | Engine, Exhaust, Transmission | 2 | 02-10-2011 11:55 PM |

| More proof of FT-86 Boxer engine appears in logo | Hachiroku | Engine, Exhaust, Transmission | 33 | 01-03-2011 02:47 AM |