Time for the porn gallery. This seems to be shaping up to be a NFG build not so much because I am trying to become the alpha GT-R around here, I've seen the apex predators around here; the best I could target is toughest hyena walking among the lions. No, it's just I have always done the work myself and to a tight budget so I had to lower expectations, settle for "good enough" solutions and watch for those things coming apart. I have enough funding to solve problems now with top shelf new parts and have better mechanics doing the work so that's what I'm going to do. Screw it, turn into the skid and go "weeeeee!"

First, the more pedestrian stuff. New Nismo motor mounts. The mounts in the car are probably sourced from a pile of used parts that were in the corner of the shop when they dropped the motor in, no thanks.

I would have gone with a Haltech if the car had a ROM-tuned OE ECU, but it already has a Power FC D-Jetro (no air flow meters needed) and while not on the level of the Haltech IMO it is still an effective solution. This, plus the fact that the shop has a ton of keyboard time on the PFC and almost none on the Haltech leads me to want to stick with that to make it easier on them to meet my expectations. I'm a picky customer so better to make it easier for them. Aren't I nice?

I did decide to increase functionality by picking up the boost control kit for the PFC so they can tune the boost levels right in the ECU and not through one more gizmo competing for space on what will be a busy dashboard. The wiring harness is old and crusty, though so I got with Wiring Specialties (great service) for a full replacement harness including coil pack and transmission harness. Again, eliminate all potential failure points and make life a little easier for the shop.

Oil control is probably the greatest focus I have on the engine build. I will not cut any corners in trying to make it bulletproof. I ran right up to the edge of picking up a dry sump system, but determined that a properly set up wet system with all the known shortcomings addressed would do the job very well. Parts are still coming, namely a Trust extended sump kit to add oil pan capacity, but here is what I have so far.

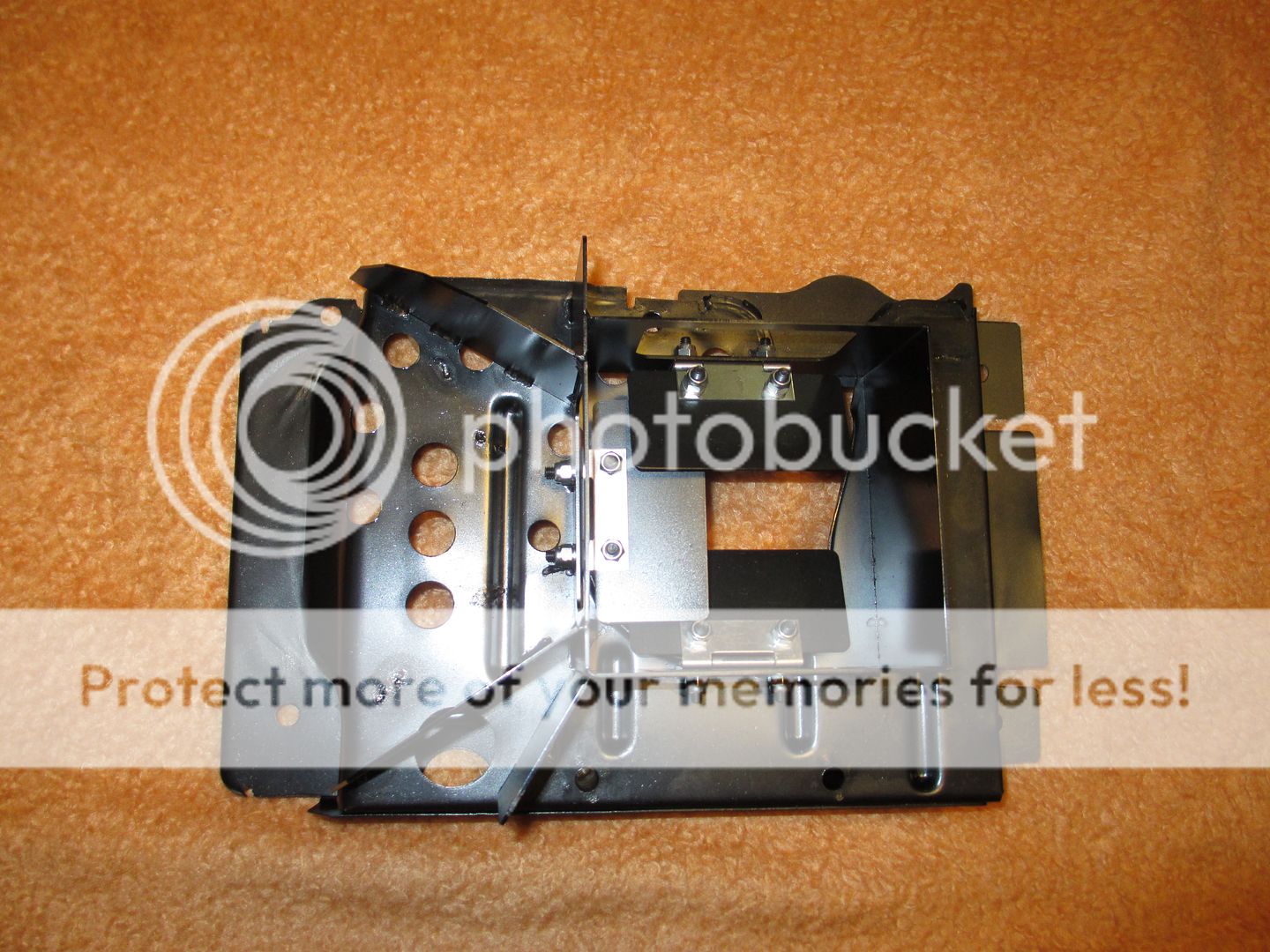

First, oil slosh. The pan has a bit of a baffle, but it's very shallow which is why I will have the sump extension welded on. There are a few aftermarket oil pan baffles out there to keep the oil pickup constantly submerged in a pool of engine blood, but I determined the Nismo to be the best. I prefer the more rugged swing doors over the rubber ones seen on other types. Secondly, there are a series of crank scrapers to slough oil off the spinning crank.

Unfortunately, this item was selected before my crank purchase fell through and I went with the stroker. I may have trouble. The extra swing on the crank IS going to nail those scrapers. At best I will be fitting and trimming for a while to adjust the scrapers to the crank throws, at worst, the rotating assembly will encroach so badly I won't be able to use it. If the latter occurs I may need to go with the lesser Tomei unit.

Another oiling issue is blowby. RB26s cough up oil through the valve cover breathers like frat boys puke up cheap beer. This has multiple causes, one of which is oil pooling in the head. Part of that is over delivery of oil to the head. This has led to Tomei selling a restricter to reduce oil to the head. Fine. It does make me wonder, though, why they would make that AND a pump that delivers a crap ton more oil than the OE unit, WTF? Either there is too much oil or there isn't, make up your mind. My theory is that oil delivery is fine if the pump doesn't explode (fixed that) and if the pump flows well (N1 pump profile, fixed that) and the pickup never sees air (fixed that). The restrictor will be used, but the oil pooling is still a problem. The drainage is not adequate. Solution, a big rear drain!

http://www.spoolimports.com/spool-oi...il-drain-kit-2

This kit removes the welsh plug from the rear of the head right where there is a big pool of oil sloshed back by G forces and trying desperately to drain down the casting passages at the same time crankcase pressure is trying to rush up. Gurgle gurgle. Better to dump down that big hose into the rear drain boss on the block. The kit is for twins so has the Y fitting, but I am going big single so the rear port can be dedicated to head drainage, Yaaa!

Now, another contributing factor to trademark RB26 blowby is the factory valve cover baffles. They allow oil to slosh back down the baffles, get stacked up and become a barrier to crankcase pressure trying to escape. The oil is thus pushed out by that pressure. Let's redesign the baffles to prevent that. Oh wait, Mines already did it. Take my money!

Blowby should be, pretty much, eliminated, but there will always be some so I will be researching and picking up a catch can system. The shop wants to fab one up, but theirs and many others have t=no level indicators, filtration nor easy ways to drain or clean them so I will likely buy one. Radium has a sweet setup that makes my junk twitch.

http://www.radiumauto.com/Universal-...s-AOS-C58.aspx