Pistons!

Everybody's got em, some people know what they do, and a select few people in the world are cool enough to design them.

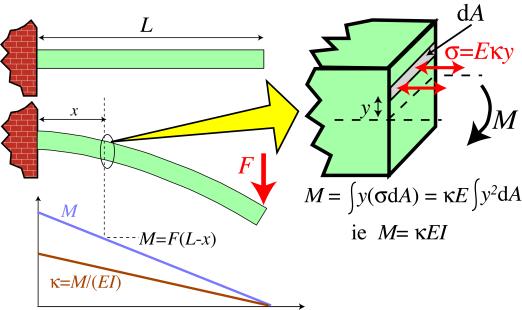

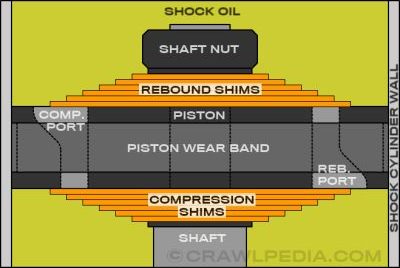

Shock absorber pistons exist to limit and direct fluid flow, in a way that dissipates energy. In most modern shocks, the piston has shims on either side to control fluid flow. Since shims are flexible, they will open when enough bending moment is applied.

If you look at the full piston assembly, you will see that the center is fixed, and the outer edges experience bending

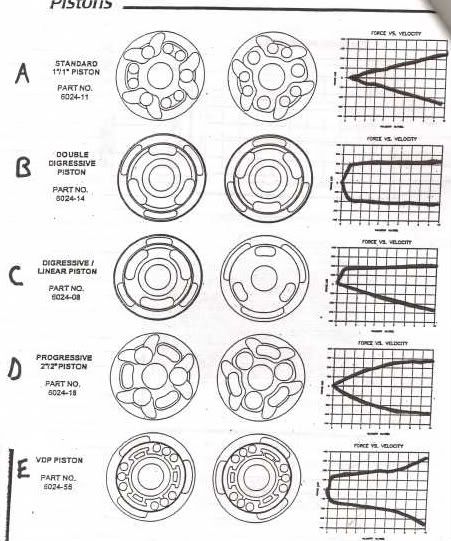

There are different types of pistons, which play with the shape and location of the compression and rebound ports. First a summary, then details.

1) Linear Pistons:

1) Linear Pistons:

A well-designed linear piston will expose the face shim to relatively uniform loading. It will also have plenty of space for shock oil to enter. Target market is usually racing, since there isn't any high-speed blow-off.

2) High Flow Linear Pistons:

As you'd expect from the name, if you're moving alot of fluid and want linear response... this is your piston. High force and high stroke applications benefit from this type of design.

3) High-Frequency Pistons:

Note the tiny holes around the perimeter. This was Ohlins' compromise that provided similar performance to a linear piston, but with a slight deadzone that moved high-frequency, low-amplitude inputs to the tires using bleed (un-shimmed pressure relief).

Link to smart people discussing it

4) Linear/Digressive Pistons:

For street applications, a linear compression setup can be a bit "crashy" if you choose an aggressive initial damping rate. This allows suspension engineers to blow-off excess force that would normally build up on a linear piston. All of the compression force is concentrated on the outside of the shims, which causes more bending moment. Also, many manufacturers include a degree or two of pre-load on the compression shim stack.

5) Digressive/Digressive Pistons:

If you want softer performance at high speed rebound, you can do the same thing as above. Blow off excess force, once sufficient pressure has built-up. Typically the rebound stack is allowed to build more force before blow-off, since this is less noticeable to the driver.

6) Velocity-Dependent Pistons

These pistons typically have a progressive-linear-digressive shape... which allows you to keep the nose of the dyno graph narrow while still providing for the high speed rolloff.

Other notes:

- Many pistons have a spot for inserting a variable bleed screw. Similar to the high frequency design, some bleed helps to minimize hysteresis by equalizing pressure during low-speed damping ... but it sacrifices some high speed responsiveness.

- You can build 2 or 3 layer shim stacks. As higher piston velocities are reached, the deeper layers will reinforce the stack. This allows for fine-tuning of high speed behavior.

For those interested in shims, I'm still learning about the different interactions. As the guys on ReStackor say, it's both simple and complex. Check out their site for some amazing explanations:

LINK