Quote:

Originally Posted by nelsmar

so @ arghx7 do you have any charts showing the effect of increased mass vs the point of MBT? As in increasing air in the chamber which would result in increased fuel changing the density or mass of the atmosphere int he chamber which would change the burn rate and time it takes until the pressure reaches the piston? As well as different compression or deck height showing how it alters where MBT is obtained? Ive always wondered this. |

You're talking about three different things: ignition delay (0-10% burn time), combustion speed (10-90% burn time), and combustion phasing for MBT.

In the ECU you set the spark timing. That's only when the secondary coil in the ignition system activates. There's a delay until the mixture really starts to burn--the most common way to represent this is the burn delay/ignition delay. That's the number of crank angle degrees from 0-10% burn. That's dependent on all sorts of things, but one of the big things is the amount of residual gas in the combustion chamber as a result of valve timing. Speed and engine load affect it, and once you talk about lean burn engines you have that playing into it.

The second thing is the combustion speed, which is often represented as the "bulk burn." It's the number of crank angle degrees from 10-90% burn. It's greatly affected by the design of the intake port (tumble and swirl flow) and also the geometric compression ratio. There's tons of other factors related to the fuel for example.

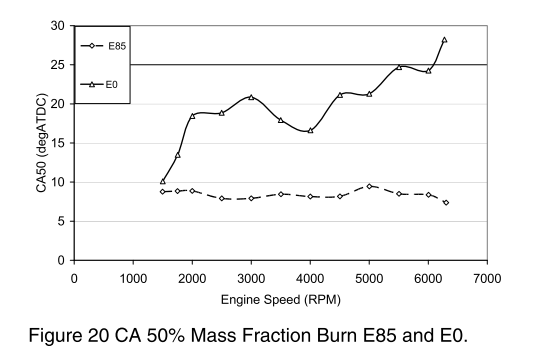

The last thing is combustion phasing. On a spark ignited, homogenous charge engine it's generally accepted that MBT is achieved when 50% burn occurs between 6-10 degrees ATDC firing. Usually the rule of thumb is 8. That

doesn't really depend on a lot of factors: it's not that sensitive to engine load, engine speed, number of cylinders. I think a lot of it just the basic physics of reciprocating piston engines. The combustion phasing is not the spark timing. The spark timing required to get a 50% burn at 8 degrees ATDC varies according to changes in burn delay (0-10%) and combustion speed (10-90%).

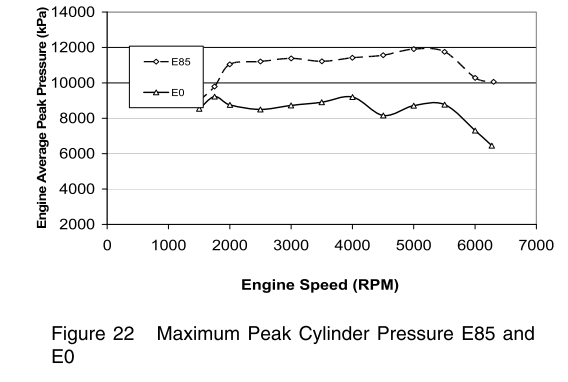

Here are some charts from an experimental GM LNF engine (found in Pontiac Solstice GXP) showing peak cylinder pressure on E85 vs E0, running at MBT (50% burn between 6 and 9 degrees ATDC) on E85 and whatever combustion phasing was needed at borderline knock condition on E0.

But you'll never know what your combustion phasing, burn delay, combustion speed, or peak pressure is without a combustion analysis system. And without that info, it will be difficult to make a link between spark timing, peak cylinder pressure, and the bearing durability question. You need a cylinder pressure sensor installed, and then you need to run different spark timing under WOT pulls and see how that affects peak pressure with E85 or race fuel. That's going to cost money--a lot more than a set of aftermarket bearings.

Unfortunately it still comes back to trial and error... run a certain setup, see if it breaks, and speculate as to why it broke and what needs to be changed to prevent it from breaking again.

I'm attaching two papers. One has some

discussion about combustion phasing/speed and engine efficiency. It's at part load condition though. The other is the

study on an E85 version of the GM LNF engine that was in the Pontiac Solstice GXP.