|

||||||

| Engine, Exhaust, Transmission Discuss the FR-S | 86 | BRZ engine, exhaust and drivetrain. |

|

|

|

Thread Tools | Search this Thread |

|

|

#15 |

|

Senior Member

Join Date: Mar 2017

Drives: Q5 + BRZ + M796

Location: Santa Rosa, CA

Posts: 7,883

Thanks: 5,668

Thanked 5,804 Times in 3,299 Posts

Mentioned: 70 Post(s)

Tagged: 0 Thread(s)

|

What do you define as fine? It looked ok from the outside? It held up for years under repeated track use, heat cycles, all while holding the weight of a T78 turbo?

People do perfect prep, while back purging pipes, and welds can still fail. Most welders would likely not want to touch such a repair job. They would want to cut the pipe at the crack and sand/prep everything then weld it back up, but because they don't have a jig, they wouldn't even want to do that. They wouldn't want to take the responsibility for it failing or not fitting.

__________________

My Build | K24 Turbo Swap | *K24T BRZ SOLD*

|

|

|

|

|

|

#16 |

|

Senior Member

Join Date: Nov 2018

Drives: brz

Location: nc

Posts: 318

Thanks: 431

Thanked 739 Times in 443 Posts

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

|

I mean it welded just like the raw pipe I rerouted around the steering arm, it was for a circle track truck. Kind of surprised it welded as well as it did since it was coated inside.

It was mild steel, it didn't need back purged and I don't know if he ever ran it on the track. So some one takes a cracked header to a welder to repair then expects the welder to guarentee it will not crack like it did from the factory.

|

|

|

|

|

|

#17 | |

|

Senior Member

Join Date: Mar 2017

Drives: Q5 + BRZ + M796

Location: Santa Rosa, CA

Posts: 7,883

Thanks: 5,668

Thanked 5,804 Times in 3,299 Posts

Mentioned: 70 Post(s)

Tagged: 0 Thread(s)

|

Quote:

Guarantee? No, but if a crack appeared after years of heat cycling then reappears within a few heat cycles then they probably would see that work returning out of pocket or someone complaining and taking their business somewhere else. Iíve seen it before.

__________________

My Build | K24 Turbo Swap | *K24T BRZ SOLD*

|

|

|

|

|

|

|

#18 |

|

Senior Member

Join Date: Nov 2018

Drives: brz

Location: nc

Posts: 318

Thanks: 431

Thanked 739 Times in 443 Posts

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

|

Well it welded fine. I guess you really have to actually have welded a lot of different materials to understand what welding fine means.

Since we are talking headers, i found a neat trick. I have been using ultra grey on the turbo flanges and v band connections. It turns into a chalky substance but it seals great. Last edited by solidsnake11; 06-23-2020 at 10:13 AM. |

|

|

|

|

|

#19 | ||

|

Senior Member

Join Date: Mar 2017

Drives: Q5 + BRZ + M796

Location: Santa Rosa, CA

Posts: 7,883

Thanks: 5,668

Thanked 5,804 Times in 3,299 Posts

Mentioned: 70 Post(s)

Tagged: 0 Thread(s)

|

Quote:

I appreciate you sharing your opinion and experience on the matter, but understand that your opinion is in the far minority. The consensus is to the contrary, that the coating will create gas and introduce contaminants that will cause porosity or weld defects. Call Jet-Hot, and see what they advise, or you can believe what this guy said when he called. https://www.hotrodders.com/forum/can...rs-115428.html Quote:

Please watch.

__________________

My Build | K24 Turbo Swap | *K24T BRZ SOLD*

|

||

|

|

|

|

|

#20 |

|

Be Kind

Join Date: Apr 2020

Drives: 2020 86

Location: MD

Posts: 1,077

Thanks: 5,152

Thanked 1,254 Times in 605 Posts

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

|

__________________

|

|

|

|

|

|

#21 |

|

Senior Member

Join Date: Nov 2018

Drives: brz

Location: nc

Posts: 318

Thanks: 431

Thanked 739 Times in 443 Posts

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

|

Are we talking about a header for a car or a space shuttle?

It was 12 years ago that I welded it but I remember it because I though man this is going to make a mess but the owner told me to weld it. Like I said it welded fine. If it welded fine for a person like me that don't back purge and doesn't do hours of prep. Then it should weld fantastic for a more majority person like you irace86. I also grind the inside of the pipe and polish it after I weld it if I am building a header. Last edited by solidsnake11; 06-23-2020 at 03:30 PM. |

|

|

|

|

|

#23 | ||

|

Senior Member

Join Date: Mar 2017

Drives: Q5 + BRZ + M796

Location: Santa Rosa, CA

Posts: 7,883

Thanks: 5,668

Thanked 5,804 Times in 3,299 Posts

Mentioned: 70 Post(s)

Tagged: 0 Thread(s)

|

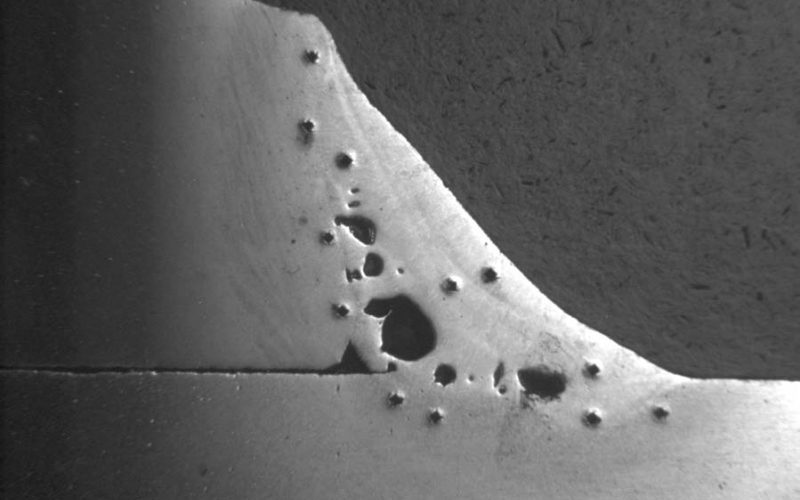

Actually, porosity isn't a lack of penetration. It is a chemical reaction between contaminants that are offing gas, or it is a reaction between oxygen in the air and the metal when it is wet/molten.

Quote:

Quote:

Again, this is about repairing a cracked header with an internal coating that can be problematic. The video I posted perfectly illustrated how simply not back purging can cause porous welds on the inside (the outside will look perfect), and now if there is also contaminants that will melt and off gases then the welds will surely be compromised. Could they last? Sure, but it is a roll of the dice like running 400+ horsepower on stock rods; weld failure is pretty much guaranteed.

__________________

My Build | K24 Turbo Swap | *K24T BRZ SOLD*

|

||

|

|

|

|

|

#24 |

|

Senior Member

Join Date: Nov 2018

Drives: brz

Location: nc

Posts: 318

Thanks: 431

Thanked 739 Times in 443 Posts

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

|

It welded just like mild steel or stainless steel. Maybe the coating shields it like the solar flux is supposed to do?

|

|

|

|

|

|

#25 | ||

|

Senior Member

Join Date: Mar 2017

Drives: Q5 + BRZ + M796

Location: Santa Rosa, CA

Posts: 7,883

Thanks: 5,668

Thanked 5,804 Times in 3,299 Posts

Mentioned: 70 Post(s)

Tagged: 0 Thread(s)

|

Quote:

Quote:

304 stainless steel melts at 2600 degrees F. http://asm.matweb.com/search/Specifi...bassnum=mq304a TIG arc is 11k degrees F. MIG is 3-20k degrees F. Unless you were welding thick headers fast, so you had no penetration then I don’t see how the coating could survive while the metal melted. See pictures in this thread on page three. Poor penetration can happen, even on a crack or seam. https://www.ft86club.com/forums/show...=140938&page=3

__________________

My Build | K24 Turbo Swap | *K24T BRZ SOLD*

|

||

|

|

|

|

|

#26 |

|

Senior Member

Join Date: Nov 2018

Drives: brz

Location: nc

Posts: 318

Thanks: 431

Thanked 739 Times in 443 Posts

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

|

I don't really care about everything your saying. I just know the coated header I welded welded fine.

I built the header on my 2jz corolla out of sch10 ss weld ells 16 years ago, I tried the solar flux but it just made a mess, I only used it on one weld. No back purge either. Just welded ground and sanded inside then polished the outside. I would say 40 hours of work. The header has yet to crack, it holds a GT4508r up and has a 175 shot and 25lbs of boost. Engine has made ~1100hp on 30lbs car ran 137mph in the 1/8. I also built the chrome moly chassis and chrome moly wheelie bars. Welded the tubs from .040 aluminum. Laid the carbon fiber up for the inside of the doors and the wing. Built the intake. Built the ecu wiring harness from scratch. Tuned the engine. It was all done in my basement. So maybe I'm not qualified to say it welded fine. The car was drove on the streets more than the track. It has a passenger seat and rides like a caddy. The guy that bought it had to have surgery because of it. He was showing out on the street, put it on the brake, let go of the button, it hooked and pulled the wheels. He wasn't prepared and it messed up his neck. It's violent when it hooks. Last edited by solidsnake11; 06-24-2020 at 12:31 AM. |

|

|

|

| The Following User Says Thank You to solidsnake11 For This Useful Post: | new2subaru (06-27-2020) |

|

|

#27 |

|

Senior Member

Join Date: Nov 2018

Drives: brz

Location: nc

Posts: 318

Thanks: 431

Thanked 739 Times in 443 Posts

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

|

|

|

|

|

|

|

#28 |

|

Senior Member

Join Date: Nov 2018

Drives: brz

Location: nc

Posts: 318

Thanks: 431

Thanked 739 Times in 443 Posts

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

|

I also almost made a deal to copy my gsxr1000 turbo header I built but I didn't want to take it off and send it overseas.

|

|

|

|

|

|

|

|

|

| Thread Tools | Search this Thread |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Anyone looking for Ceramic Coating on their 86? | drew935 | Northern California | 0 | 07-06-2019 04:33 PM |

| Thermal Barrier Coating Ceramic Coating for Exhaust and More | Dadajair | Southern California | 2 | 03-25-2019 10:09 PM |

| ceramic coating | eddiev116 | NY / NJ / CT / PA | 3 | 02-06-2015 05:54 PM |

| Ceramic Coating options or Jet hot coating | brzadmir | NY / NJ / CT / PA | 4 | 07-10-2013 12:35 PM |