|

||||||

| Suspension | Chassis | Brakes -- Sponsored by 949 Racing Relating to suspension, chassis, and brakes. Sponsored by 949 Racing. |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

FT86Club Official Vendor

Join Date: Mar 2013

Drives: Subarus

Location: Midwest

Posts: 156

Thanks: 18

Thanked 134 Times in 60 Posts

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

|

Hancha Rear Toe Link

The group buy is now open!

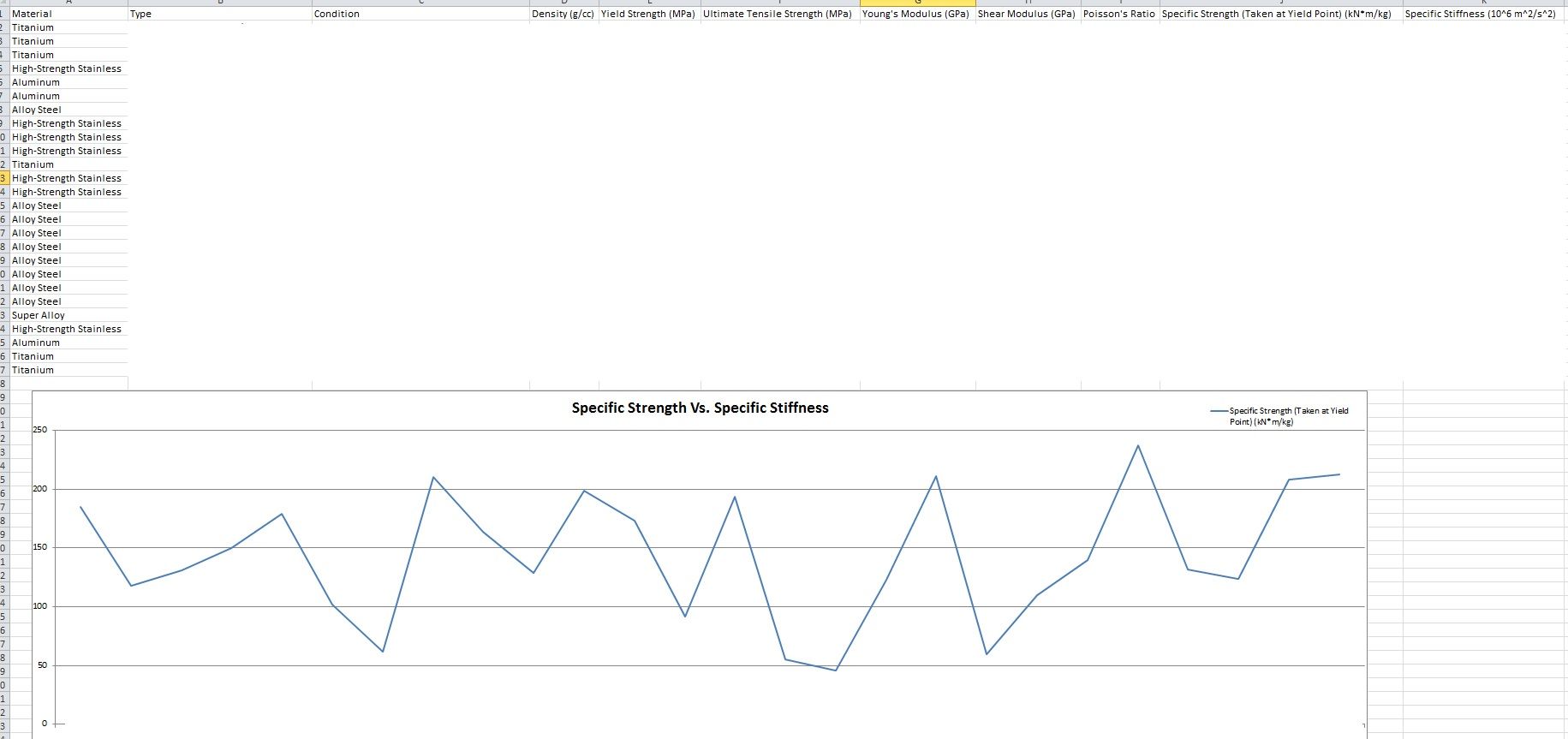

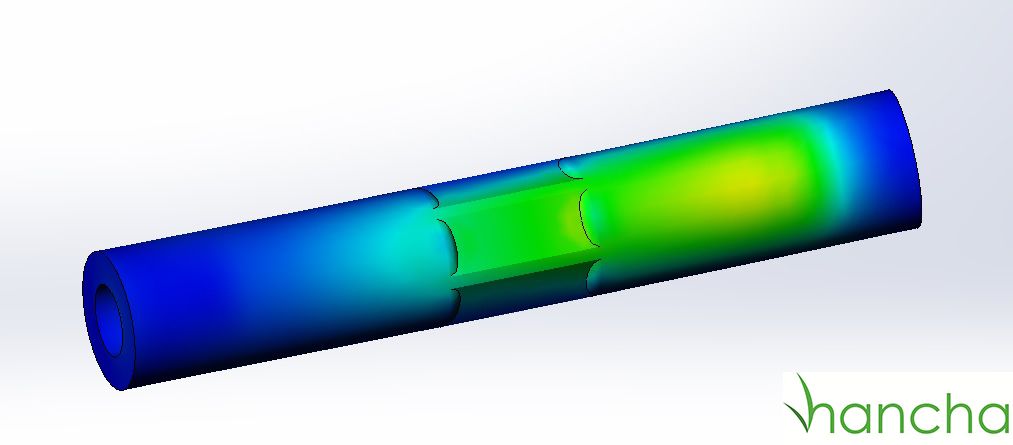

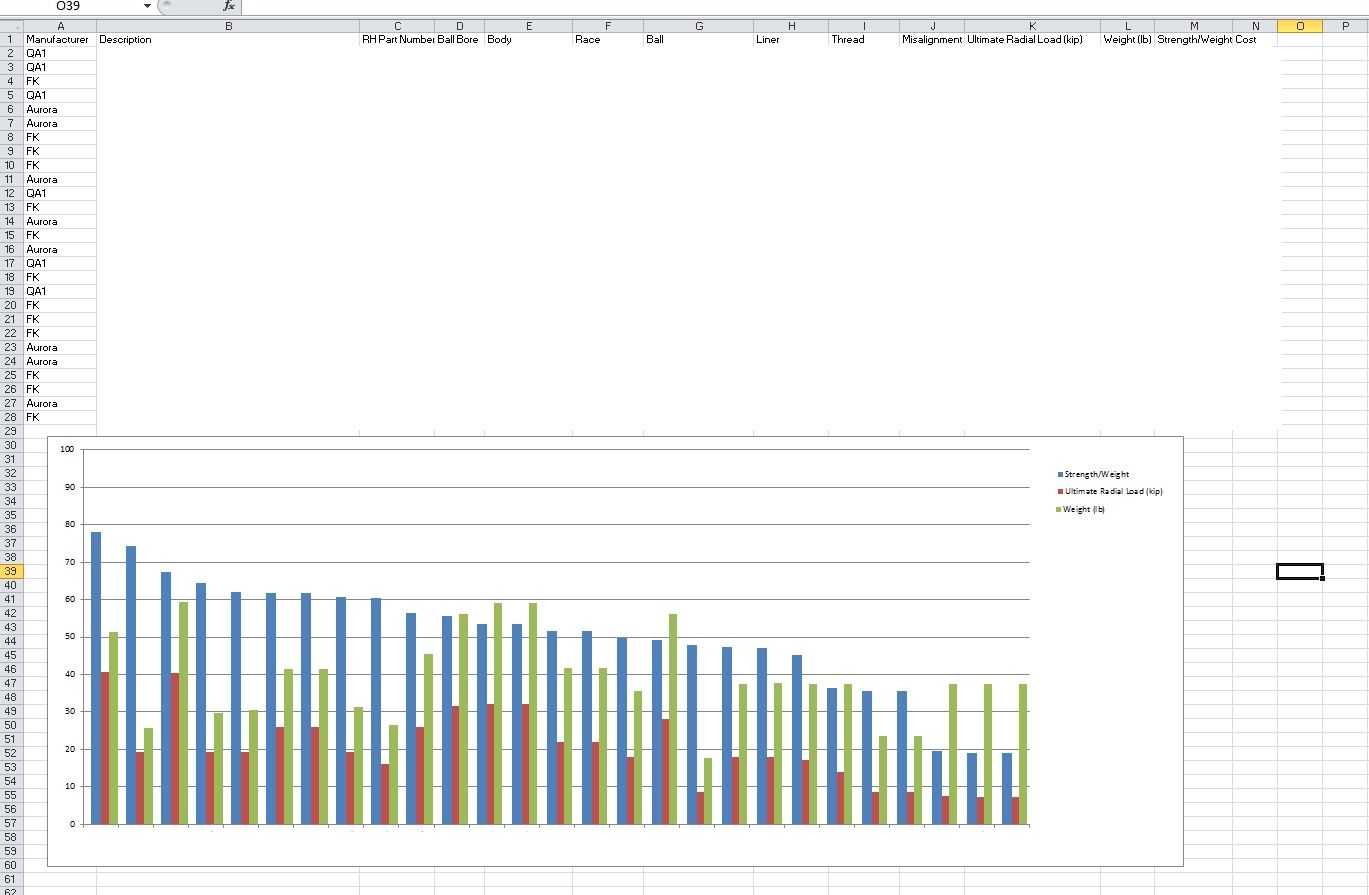

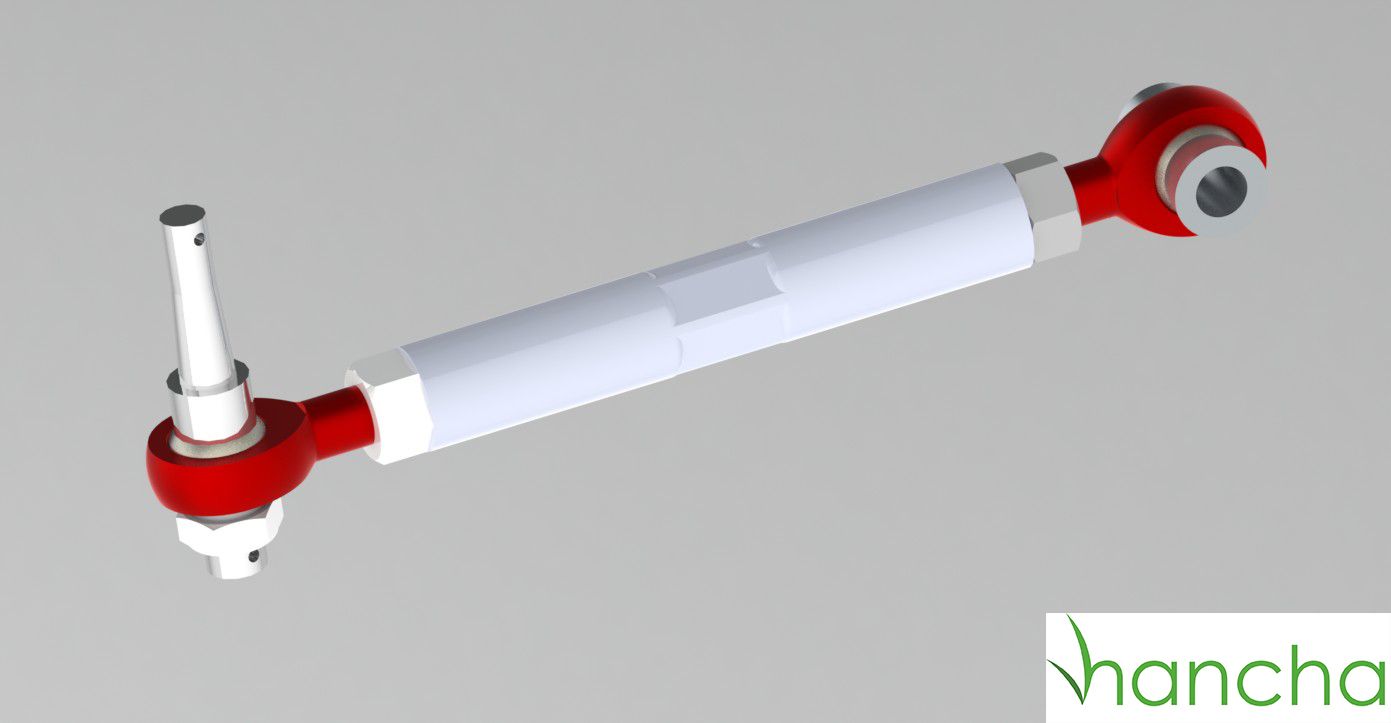

Check it out over here: http://www.ft86club.com/forums/showt...506#post804506 Hi everybody, I just wanted to let everyone know about the rear toe link we have had in development for the last few months. I also wanted to give you a little insight on our commitment to safety and quality. First, we considered the loading conditions the car would see during track conditions. We also considered the case of the wheel smacking a curb. Then we set about finding an appropriate material for the turnbuckle. We took into account stress, displacement, weight, corrosion, fatigue, and cost. We compared materials and designs on how to best meet our design requirements.  We finally settled on aluminum alloy. I cannot name the specific alloy because it is a trade secret, but it is as strong as 2024, with the corrosion resistance of 6061. The design and FEA is the easy part.  With that settled we went about selecting the appropriate rod end. To do this we directly compared various rod ends available. We also had to consider the possibility of galvanic corrosion if we mated a steel rod end into an aluminum turnbuckle. We considered threaded inserts into the turnbuckle, but we were able to find a suitable aluminum rod end  (Information intentionally omitted because China and copycats can do its own research) The most difficult and nerve wracking part was designing the shank. People discuss whether the taper is necessary or not, and if you are using a suitable material that can handle the added stress and has enough fatigue resistance, then you can indeed get rid of the taper. However, there will be more displacement because there is no longer the cast iron knuckle pushing back against it. We decided to keep the taper. Since the design envelope is the same as the OEM piece, we went with a high-strength stainless steel for the shank material. The alloy is about twice as strong as 4130 with the added benefit of corrosion resistance. Luckily there was no need to FEA here since the design is the same, but with a much stronger steel. We got the prototype back and here's a side-by-side comparison of the OEM link and our link  Installed on the car  The only issue we ran into was that because we used a castle nut on the bottom of the shank, it was too long and touched the e-brake cable. Our production version will use a stainless-nylon lock nut allowing us to shorten it by 10mm. A rendering of what the final production version will look like  We could've said, "Make it out 6061 or 4130 and call it a day! We'll use the name recognition and versatility of those alloys to carry us." We didn't, we did our research to bring you the best product possible. We took corrosion resistance seriously because even though this is an off-road product, people will daily their cars with it, I know this. And there's nothing more frustrating than not being able to install a part because everything's seized together. That is why everything is a corrosion resistant aluminum or stainless. We're not saying this stuff won't rust, but it shouldn't seize up on your after driving your car through salt and snow. This is just the tip of the iceberg. Imagine if we take something as simple as a toe link this seriously, what we can do with the more fun bits! We are finalizing the production drawings and working with our manufacturer and suppliers to finalize pricing. We expect to have pricing Tuesday and will be offering an initial group buy later this week so for those interested, keep an eye out.

__________________

Last edited by Hancha Group; 03-21-2013 at 03:25 PM. |

|

|

|

| The Following 6 Users Say Thank You to Hancha Group For This Useful Post: | akuhei (03-16-2013), colHolm (03-19-2013), eckoflyte (03-16-2013), illmatic (03-19-2013), Racecomp Engineering (03-17-2013), TouchMyHonda (03-18-2013) |

|

|

#2 |

|

Senior Member

Join Date: Jun 2012

Drives: Toyota 86 GTS

Location: Sydney

Posts: 246

Thanks: 45

Thanked 47 Times in 33 Posts

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

|

Subscribed

|

|

|

|

|

|

#3 |

|

Senior Member

Join Date: Dec 2012

Drives: 2013 Scion FR-S Argento

Location: Houston, TX

Posts: 190

Thanks: 71

Thanked 29 Times in 23 Posts

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

|

sexy looking :-)

|

|

|

|

|

|

#4 |

|

Senior Member

Join Date: Jun 2012

Drives: 99' M3, 13' SWP Brz

Location: Durham/Pinehurst, NC

Posts: 346

Thanks: 89

Thanked 85 Times in 67 Posts

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

|

sounds good. Id be happy to test

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Jun 2012

Drives: Toyota 86 GTS

Location: Sydney

Posts: 246

Thanks: 45

Thanked 47 Times in 33 Posts

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

|

I'm from Sydney Australia. Would it be possible to still participate in the group buy?

|

|

|

|

|

|

#6 | |

|

Senior Member

Join Date: Nov 2012

Drives: Subarus

Location: Nowhere

Posts: 189

Thanks: 20

Thanked 129 Times in 66 Posts

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

|

thanks but right now our test driver has been driving on them and the initial feedback is positive. I told him to do his worst to try to destroy them thanks but right now our test driver has been driving on them and the initial feedback is positive. I told him to do his worst to try to destroy them Quote:

I can work something out for shipping internationally. I can work something out for shipping internationally.

|

|

|

|

|

|

|

#7 |

|

Vtec Jesus

Join Date: Jul 2012

Drives: 13 BRZ, 13 Golf R, 15 Audi S4

Location: LSD

Posts: 1,165

Thanks: 623

Thanked 243 Times in 153 Posts

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

|

I was personally present during the install on said test car. I can attest to the beautiful finish and overall strength design. The components and material used are far superior than most of the junk you see sold on the net. I took the arm apart myself and inspected the design and was certainly impressed. Good work guy's!

|

|

|

|

| The Following User Says Thank You to TouchMyHonda For This Useful Post: | EarlQHan (03-19-2013) |

|

|

#8 |

|

Kuruma Otaku

Join Date: Dec 2009

Drives: Mk3 Supra with Semi-built 7MGTE

Location: Greater Vancouver (New West)

Posts: 6,854

Thanks: 2,398

Thanked 2,265 Times in 1,234 Posts

Mentioned: 78 Post(s)

Tagged: 2 Thread(s)

|

I your blog you mention going for stiffness to weight as a priority. But then you chose aluminum over chrome-moly. Why, when aluminium has much lower E modulus? (It's hard to see how much of a diameter change on your part vs stock.)

Also, why bother with a nonstandard aluminum alloy (26xx?) when the rod-ends are 7075?

__________________

Because titanium. |

|

|

|

| The Following User Says Thank You to Dimman For This Useful Post: | SkullWorks (03-19-2013) |

|

|

#9 |

|

Senior Member

Join Date: Aug 2012

Drives: 2013 FR-S Ultramarine

Location: Temecula, CA

Posts: 959

Thanks: 288

Thanked 560 Times in 269 Posts

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

|

On the first point, aluminum can be made larger in diameter and higher in thickness while maintaining similar weight as a chromoly part. This allows for a stiffer part at the same weight that is going to be less fragile.

Aluminum bicycle frames can be punishingly stiff due to the large diameter tubes used. Steel frames can be made just as light, but the superlight steel frames are prone to damage as the wall thickness is so low. This is also problematic for mounting of hardware. Stiffness for a composite part such as this is a combination of the entire system's stiffness. There are still gains to be made by stiffening the bulk of the material even if the rod ends have some flex. The rod end composes such a short part of the total length that I could see stiffness benefits overall happening choosing a stiffer alloy for the rest.  Just some possible explanations I can think of. Nathan |

|

|

|

| The Following User Says Thank You to SubieNate For This Useful Post: | Dimman (03-19-2013) |

|

|

#10 | |

|

Kuruma Otaku

Join Date: Dec 2009

Drives: Mk3 Supra with Semi-built 7MGTE

Location: Greater Vancouver (New West)

Posts: 6,854

Thanks: 2,398

Thanked 2,265 Times in 1,234 Posts

Mentioned: 78 Post(s)

Tagged: 2 Thread(s)

|

Quote:

__________________

Because titanium. |

|

|

|

|

|

|

#11 |

|

Banned

Join Date: Jan 2012

Drives: Attitude

Location: MD

Posts: 10,046

Thanks: 884

Thanked 4,889 Times in 2,902 Posts

Mentioned: 123 Post(s)

Tagged: 4 Thread(s)

|

I'm trolling when I say this as I know nothing about metal or the work that went into these.

But @Dimman, the rod ends are RED. RED!! |

|

|

|

| The Following User Says Thank You to OrbitalEllipses For This Useful Post: | D1cker (03-21-2013) |

|

|

#12 | |

|

Kuruma Otaku

Join Date: Dec 2009

Drives: Mk3 Supra with Semi-built 7MGTE

Location: Greater Vancouver (New West)

Posts: 6,854

Thanks: 2,398

Thanked 2,265 Times in 1,234 Posts

Mentioned: 78 Post(s)

Tagged: 2 Thread(s)

|

Quote:

'Red as standard' Not exclusively red. (If they are QA1 ends.) If you ask nicely, and pay a few more dollars you can probably get any of the normal anodizing colours. Blue, black, clear, red, purple, gold, off the top of my head.

__________________

Because titanium. |

|

|

|

|

|

|

#13 |

|

Senior Member

Join Date: Sep 2012

Drives: BRZ/E30/IS300/LS400

Location: Chicago

Posts: 293

Thanks: 25

Thanked 306 Times in 104 Posts

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

|

Considering I got the opportunity of being the first test mule for these toe links I thought in addition to giving the guys at Hancha feedback on the part I might as well share my thoughts/experiences so far with everyone on here.

The fit and finish on these things is fantastic. As much as I'm not the type of guy that's all about things being made in US, I like knowing that these toe arms were designed and made in the US and to a very high standard. The link is much beefier than your typical toe arms (about the thickness of the axles), which is confidence inspiring considering my cars typically take a beating. I haven't gotten an actual alignment yet as I'm waiting to pick up rear control arms next week, so for now a good eyeballed alignment will have to do. Adjustment was easy and straightforward, and the rod ends thread way into the rod so they have A LOT of adjustment in them. I'll be sure to report back after I take the car to the track, but so far I've just been commuting and doing a little hard driving on the street, and the car feels great.

__________________

RISKY DEVIL // ILL PHOTOGRAHY

|

|

|

|

|

|

#14 |

|

Senior Member

Join Date: Oct 2012

Drives: Black frs project

Location: Socal

Posts: 960

Thanks: 189

Thanked 886 Times in 381 Posts

Mentioned: 190 Post(s)

Tagged: 1 Thread(s)

|

pricing?

|

|

|

|

|

|

|

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| An introduction to Hancha Group | Hancha Group | Announcements, Contests, Giveaways | 23 | 05-26-2013 11:56 AM |

| Delete | driver01 | Suspension | Chassis | Brakes -- Sponsored by 949 Racing | 0 | 08-31-2012 08:42 PM |

| Gearbox: Cable Link or Mechanical Link? | Marrk | BRZ First-Gen (2012+) -- General Topics | 42 | 07-01-2012 11:45 PM |