|

|

#337 | |

|

Senior Member

Join Date: Jun 2012

Drives: DGM BRZ limited

Location: Indiana

Posts: 366

Thanks: 98

Thanked 145 Times in 95 Posts

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

|

Quote:

|

|

|

|

|

|

|

#338 | |

|

Senior Member

Join Date: Feb 2013

Drives: WR Blue BRZ, 240Z

Location: Amongst the twisty roads

Posts: 587

Thanks: 21

Thanked 412 Times in 206 Posts

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

|

Quote:

"There's that word again. "Heavy." Why are things so heavy in the future? Is there a problem with the Earth's gravitational pull?"

__________________

Phantom ESC, ECUtek Tune, Nameless Front Pipe & Axle Back, Enkei RS+M 17x8 et35, OEM+Ref

|

|

|

|

|

| The Following User Says Thank You to Gary in NJ For This Useful Post: | neutron256 (09-04-2013) |

|

|

#339 | |

|

Senior Member

Join Date: Jan 2012

Drives: '13 GBS Subaru BRZ

Location: Minneapolis, MN

Posts: 2,030

Thanks: 680

Thanked 664 Times in 382 Posts

Mentioned: 26 Post(s)

Tagged: 1 Thread(s)

|

Quote:

-Sunforce -Battery Doctor -Projecta -WirthCo Battery Doctor/WirthCo seems to be the most US distributer. I just ordered it through amazon for $78 free shipping w/Amazon Prime. The question now is... Is is a piece of crap? Reviews I've found on it seem good.

__________________

-Fortes fortuna adiuvat (Fortune favors the bold)

|

|

|

|

|

|

|

#340 |

|

Member

Join Date: Aug 2013

Drives: 2001 NB MX-5

Location: Victoria, BC

Posts: 20

Thanks: 3

Thanked 3 Times in 3 Posts

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

|

So that battery isolator should take the place of some of the relays in the 12v P/24V S set-up then. It should allow both batteries to charge at 12V when they aren't connected in series.

So this now could be as easy as a single relay connecting the batteries in series. I still think a small 12v battery will be required for the car's electronics however. -Grant |

|

|

|

|

|

#341 | |

|

Senior Member

Join Date: Jun 2012

Drives: DGM BRZ limited

Location: Indiana

Posts: 366

Thanks: 98

Thanked 145 Times in 95 Posts

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

|

Quote:

However, if you used this relay for that one place it could be used, you would still need another normally closed relay to connect the grounds. If you use a single pole dual throw relay you can get away with two relays total. Or as the case may be with me, two banks, since I plan to use multiple smaller rated relays grouped together instead of big ones. (technically four banks since I am planning a 36v setup) |

|

|

|

|

|

|

#342 |

|

Member

Join Date: Aug 2013

Drives: 2001 NB MX-5

Location: Victoria, BC

Posts: 20

Thanks: 3

Thanked 3 Times in 3 Posts

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

|

I'm thinking of the diode isolator.

-Grant |

|

|

|

|

|

#343 |

|

Senior Member

Join Date: Jun 2012

Drives: DGM BRZ limited

Location: Indiana

Posts: 366

Thanks: 98

Thanked 145 Times in 95 Posts

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

|

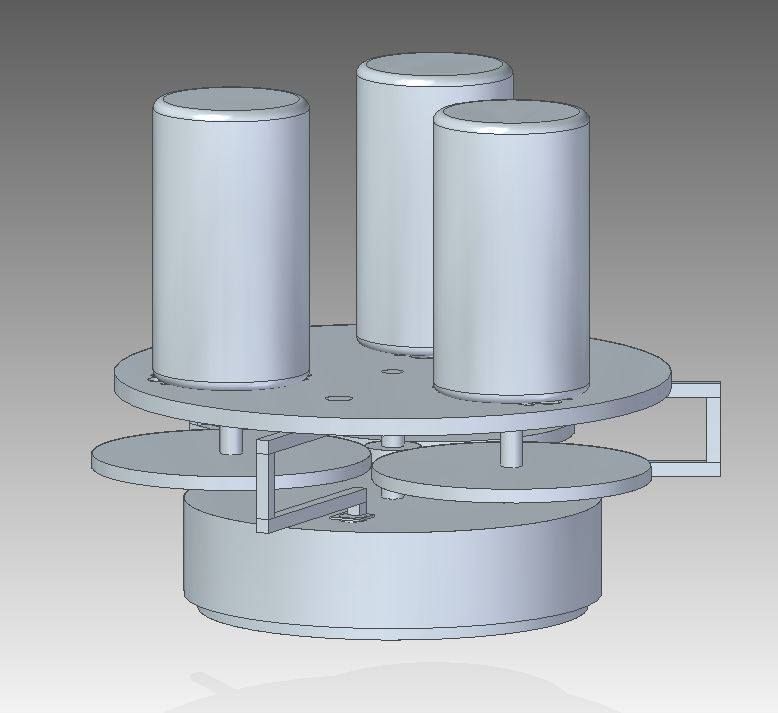

Ok, so. My gf has been doing some cad work for me. She has very little cad experience, but more than my none, so she has been a big help. Half of this has been done away from where I could show her what I was meaning, but as a proof of concept this does well.

But, it isn't complete as can be seen in several areas. Half the dimensions are just guesses as I don't have a turbo picked out yet. The cad motors are sized to the aquastar t20's although I am not planning on using them now. As I've said recently I am currently planning on a 36v setup using some AGM batteries. Ive now bumped the size I want up to models that can run 750 cranking amps, and 50ah or so. I might go higher, we will see. Removing the front battery will leave me with a weight gain of 50 lbs or so, but this isn't bad considering how I wanted more battery for my stereo anyways. If I get something and it turns out to not be enough ill probably add in a capacitor setup as well. Or I may just go with smaller batteries and run a capacitor bank. We will see. For motors I'm looking at some of the leopard motors. I am hoping to be able to run the 58110 or 56110 series but am having a hard time sourcing them. Each motor is rated 7600 watts, and I would go with the 960 kv one. Second choice is the 5898 or 5698 series, which I definitely have access to. They have a 1100kv model which would work ok with 36v, rated 6500 watts. As you can see in the model with this setup I will have the chance to take advantage of motors with lower max rpm because I can just gear it up, and multiple motors for more total power. I will probably be starting with two motors, then stepping to three once I am ready to go for more power. With 3 motors I can do up to a 1:6 gear ratio, which of course will take the 30k max rpm of the motors up as high as I could want with a turbo. On the model right now is a 1:5 ratio just to see how it looks. I would be starting off probably 1:3 or so since it will get me where I want to be for testing and have more teeth meshing on the gears. If I find I need to step to 4 motors, Ill just have to use two pinion gears on the shaft and offset two motors to get the gear ratio I need. And of course upgrade my electrical most likely, lol. That would get me to the 25kw range max power which is a crapton to deal with. The one saving grace I have here is how extremely low of a duty cycle Ill be running. The times Ill actually want full power will be short and a long time between. I may still need to upgrade my alternator etc, but Ill just write that off as another combined with audio expense, lol. Gears may be a problem. I'm planning on using 1/5 scale r/c gears which are designed for these motors, so theoretically they should hold up well. If I end up having to replace pinion gears often, I won't be too mad. They are cheap in the grand scheme of things. Bearings were talked about awhile back, but I have some ceramic hybrid bearings reasonably picked out that are rated just shy of 100k rpm. They should hopefully hold up alright. Again if I blow one occasionally, I won't be too mad. The controller has been discussed a bit in past pages as well, so I'm not going to go into that either. Now I need to put in a reminder with the picture that THIS ISN'T COMPLETED. Its just a rough proof of concept. Notable things that aren't done is the size of the base that will sit in the turbo housing and the mounts between the two plates. Obviously the round things are gears, ain't nobody got time fo teefs. (Edit: I also just noticed it somewhat looks like the big gears are touching each other from this angle. They aren't. Each large gear is only touching the center small gear.)  I was having a hard time communicating to my gf through text exactly how to finish the lower plate, so we just left it for now. It will of course be a lot thinner for a good portion in order to fit under the snap ring. It started at this thickness for the shaft bearings. The mounts between the two plates will of course be much larger, and less sharp. Feel free to pick at anything you see here. Obviously I'm still in early planning stages, and though there are many obstacles that Ill need to find a way around, I haven't found anything insurmountable yet. Ill try to answer the best way I can and/or work through some details. |

|

|

|

| The Following User Says Thank You to rusty959 For This Useful Post: | DAEMANO (09-05-2013) |

|

|

#344 |

|

Senior Member

Join Date: Jan 2012

Drives: '13 GBS Subaru BRZ

Location: Minneapolis, MN

Posts: 2,030

Thanks: 680

Thanked 664 Times in 382 Posts

Mentioned: 26 Post(s)

Tagged: 1 Thread(s)

|

Quote:

Sorry I haven't sent you my CAD design for the compressor backplate yet. I haven't logged on to my CAD PC in a few days. Today is the one day a week I go into the office but I'll try and remember to send it to you when I get home. If anyone else wants any of my CAD designs just PM me your email, and what file type you'd like. I work in RhinoCAD but can export to most file types. Eventually I'll post them for anyone who wants access, but they're still a work in progress and I don't like to post somethign that's half finished. A couple of thoughts on the design: -If you can seal the transmission housing it will probably extend the life of the gears greatly. At those speeds even a little dust can quickly tear them up. -The connection between the top and bottom plate needs to be stronger (could be worked into a sealed housing) -Are you running seperate ESC's for each motor? With this design even a slight variance in speed, and possibly just relitive position of the motor windings could cause the motors to end up fighting each other. If I have some time I might play around with your design some in CAD and see what I can come up with. Something integrated into the backplate of the compressor shouldn't be too hard. I like the concept, but with the forces involved my gut tells me it will self destruct. It will be interesting to see the results.

__________________

-Fortes fortuna adiuvat (Fortune favors the bold)

|

|

|

|

|

|

#345 |

|

Banned

Join Date: Nov 2012

Drives: it has 4 wheels and a motor

Location: Planet Earth

Posts: 479

Thanks: 69

Thanked 173 Times in 93 Posts

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

|

rusty that's a great thought but wouldn't you think it's better to take baby steps and use 2 motors before you use 3?

just for my piece of mind make sure the motor gears don't touch each other, only the motor main fan shaft. There's is going to be a LOT of torque so you need to make sure those motor mounts are REALLY beefed up. Also it worries me that you say you guys don't have much experience with CAD. Gears are not joke. it's a very meticulous thing to get to work just right. |

|

|

|

|

|

#346 | ||

|

Senior Member

Join Date: Jun 2012

Drives: DGM BRZ limited

Location: Indiana

Posts: 366

Thanks: 98

Thanked 145 Times in 95 Posts

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

|

Quote:

Quote:

|

||

|

|

|

| The Following User Says Thank You to rusty959 For This Useful Post: | neutron256 (09-05-2013) |

|

|

#347 |

|

Senior Member

Join Date: Jan 2012

Drives: '13 GBS Subaru BRZ

Location: Minneapolis, MN

Posts: 2,030

Thanks: 680

Thanked 664 Times in 382 Posts

Mentioned: 26 Post(s)

Tagged: 1 Thread(s)

|

@rusty959, Do you have Specific gears in mind? I'm looking at various sources for gears especially those that provide CAD files for their products.

__________________

-Fortes fortuna adiuvat (Fortune favors the bold)

|

|

|

|

|

|

#348 | |

|

Senior Member

Join Date: Jun 2012

Drives: DGM BRZ limited

Location: Indiana

Posts: 366

Thanks: 98

Thanked 145 Times in 95 Posts

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

|

Quote:

http://www.hpiracing.com/en/part/108730 - pinion gears for the center http://www.integy.com/st_prod.html?p...6#.Uiin6T_4IQk - spur gears for the motors. I was considering doing a composite gear for the motors, but am considering just doing the steel as I linked to. Most of the composite gears ive seen for those size are set up for a different type of slipper clutch and so would be hard to make a mount for the motor. With that steel one, I can just make a relatively simple adapter to fit the motor. Plus then I would expect the pinion gear to wear out faster, which is an easier change than multiple spurs bolted down in multiple places. I doubt you can find cad files for these gears specifically, but I'm sure some general mod 1.5 gear files are available somewhere. When I get to gears more in depth I might see what else is available outside the R/C world, but so far ive just been sticking to what I know. |

|

|

|

|

|

|

#349 | |

|

Senior Member

Join Date: Jan 2012

Drives: '13 GBS Subaru BRZ

Location: Minneapolis, MN

Posts: 2,030

Thanks: 680

Thanked 664 Times in 382 Posts

Mentioned: 26 Post(s)

Tagged: 1 Thread(s)

|

Quote:

The largest I could find is 36mm with an 8mm center bore. Which would probably be pefrect if you were using smaller 36mm motors. Of course this will also depend on the size of the pinion gear used.

__________________

-Fortes fortuna adiuvat (Fortune favors the bold)

|

|

|

|

|

|

|

#350 | |

|

Senior Member

Join Date: Jun 2012

Drives: DGM BRZ limited

Location: Indiana

Posts: 366

Thanks: 98

Thanked 145 Times in 95 Posts

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

|

Quote:

|

|

|

|

|

|

|

|

|

|

| Tags |

| hairdyerperformance, only pulls hard one gear |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Full throttle Electric Supercharger Build Thread | fenton | Forced Induction | 11295 | 02-19-2024 03:42 PM |

| DUP THREAD MODZ PLZ DELETE KTHX | SloS14 | Forced Induction | 0 | 07-09-2013 05:41 PM |

| Electric Turbocharger | Shankenstein | Forced Induction | 91 | 06-24-2013 02:47 PM |

| Electric 86 | frosty86 | Scion FR-S / Toyota 86 GT86 General Forum | 8 | 11-10-2012 02:16 PM |

| WRX Electric turbo | Neilus | Engine, Exhaust, Transmission | 42 | 05-03-2012 09:20 PM |