|

|

#71 | |

|

Undisputed El Presidente

Join Date: Jun 2012

Drives: Zenki 37J ZN6

Location: Stockton, CA

Posts: 11,573

Thanks: 9,383

Thanked 9,399 Times in 5,262 Posts

Mentioned: 374 Post(s)

Tagged: 33 Thread(s)

|

Quote:

I'll try to look into finding the piston sizes for everything so the right people can figure this out. I probably could do the math if someone gave me a formula (hell, I'll try to look that up too) |

|

|

|

|

|

|

#72 | |

|

Senior Member

Join Date: May 2014

Drives: 2013 Subaru BRZ

Location: Pontiac, MI

Posts: 313

Thanks: 187

Thanked 196 Times in 101 Posts

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

|

Quote:

__________________

1jz salvaged brz build thread brought to you by visconti tuning --> Pipe dreams and poor life choices

|

|

|

|

|

|

|

#73 |

|

Wish Nissan made one

Join Date: Feb 2012

Drives: '13 WRB BRZ Premium

Location: Lake Orion, MI

Posts: 886

Thanks: 129

Thanked 360 Times in 189 Posts

Mentioned: 18 Post(s)

Tagged: 1 Thread(s)

|

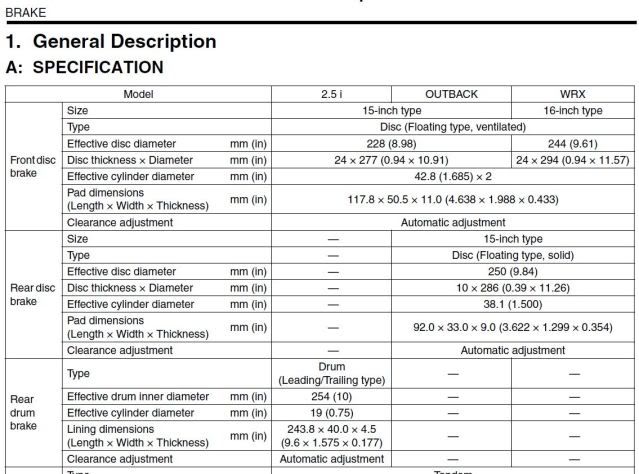

I did some more research on caliper piston sizes.

From what I can tell, the BRZ has the same brake calipers as the 09 WRX.. Right?  So based on this chart, the WRX has 42.8mm from pistons (x2) and a single 38.1mm rear piston. The Z32 calipers have 40.45mm front pistons (x4) and 38.1 mm rear pistons (x2). Simple math (40.45/42.8) says thats about a 5.5% reduction in clamping power. It's probably more like 8% if you use a proper goemetric equation for area of a circle. If the leverage increase by using the larger disc gets you 5%+ back.. then the brake bias is only changed by maybe 3%.. which is probably not noticable. I think this is what Dave has been concluding so far. I will also get a measurement myself on my actual brakes since I have both at home.. but I have to wait until I actually get home to do it.. so I'll do that this weekend. I'm also going to punch these figures and the bigger rotor diameter into the brake bias calculator (later today when I have some free time) and I'll see what it shows. |

|

|

|

| The Following User Says Thank You to eikond For This Useful Post: | finch1750 (07-18-2014) |

|

|

#74 | |

|

Site Moderator

Join Date: Dec 2010

Drives: Stuff

Location: Florida

Posts: 10,317

Thanks: 955

Thanked 5,965 Times in 2,689 Posts

Mentioned: 262 Post(s)

Tagged: 8 Thread(s)

|

Quote:

All USDM (and ROW "High Spec") have 2010+ or whatever Legacy GT rear brakes, only the fronts are WRX spec.

__________________

-Dave

Track cars: 2013 Scion FRS, 1998 Acura Integra Type-R, 1993 Honda Civic Hatchback DD: 2005 Acura TSX Tow: 2022 F-450 Toys: 2001 Chevrolet Corvette Z06, 1993 Toyota MR2 Turbo, 1994 Toyota MR2 Turbo, 1991 Mitsubishi Galant VR-4 Parts: 2015 Subaru BRZ Limited, 2005 Acura TSX Projects: 2013 Subaru BRZ Limited track car build FS: 2004 GMC Sierra 2500 LT CCSB 8.1/Allison with 99k miles |

|

|

|

|

|

|

#75 |

|

The Legacy777 spreadsheet that Ryephile linked to could probably be tweaked to get you the right numbers for the Z32 caliper + LGT rotor combo and compare to stock BRZ.

- Andy |

|

|

|

|

|

|

#76 |

|

Wish Nissan made one

Join Date: Feb 2012

Drives: '13 WRB BRZ Premium

Location: Lake Orion, MI

Posts: 886

Thanks: 129

Thanked 360 Times in 189 Posts

Mentioned: 18 Post(s)

Tagged: 1 Thread(s)

|

Based on this link. http://legacygt.com/forums/showthrea...ize-18615.html

the rear piston for leg gt is also 38.1mm. So it should be same for brz and frs I used this online bias calculator: http://www.tceperformanceproducts.com/bias-calculator/ Stock: front piston size (inches) = 1.685 and 1.685 (42.8mm) front pad cf I left at .48 (street performance example) front rotor diameter 11.575 front pad height (I left at 1.875.. not sure how to calc this so I left it at the prefilled value) rear piston size = 1.49999 (38.1mm) rear rotor diameter = 11.42 rear pad cf = .48 (same as above) rear pad height = 1.25 (left at prefilled value) Result = Front brake bias 0.697 or 69.7% to front. Z32 brakes: front piston size (inches) = 1.5925 and 1.5925 (40.45mm) front pad cf I left at .48 (street performance example) front rotor diameter 12.44 front pad height (I left at 1.875.. not sure how to calc this so I left it at the prefilled value) rear piston size = 1.49999 (38.1mm) rear rotor diameter = 11.42 rear pad cf = .48 (same as above) rear pad height = 1.25 (left at prefilled value) Result = Front brake bias 0.709 or 70.9% to front. So the Z32 swap that I have on my car changes the front bias from 69.7% to 70.9% or a variance of 1.2%. If my data is correct.. and it's probably not perfect yet as I don't have the pad height calcs.. Dave is correct that the WRX 4-pots brakes would move brake bias to the back. I did the calcs with the stock BRZ front rotor and the new pistons.. The bias came to 67.2. So doing WRX 4-pots moves braking rear-ward by 2.7%. But, when you add the bigger leg gt front rotor the added leverage moves the bias back to the front to a new bias is 70.9%. So you gain 1.2% front bias with this setup. Is 1% change in brake bias noticeable in a void of nannies like EBD? Would EBD make up for it before even a trained professional noticed the difference? I'll see if I can complete this analysis this weekend. I'll measure the caliper pistons myself so I have first-hand knowledge and I'll see if I can figure out this pad redial height topic as well. Last edited by eikond; 07-18-2014 at 11:59 AM. |

|

|

|

|

|

#77 |

|

Join Date: Feb 2012

Drives: 2012 BRZ Premium WRB 6MT

Location: Charlotte NC

Posts: 695

Thanks: 227

Thanked 1,415 Times in 379 Posts

Mentioned: 80 Post(s)

Tagged: 3 Thread(s)

|

Holy monkey! Didn't expect this one to turn into a physics symposium!

Dave-ROR is correct doubling the piston area on a slider caliper. Hydraulic pressure x The effective area of the pistons on one side of the caliper= One sided linear mechanical force generated by the caliper The caliper reacts to that one-sided mechanical force by turning it into a clamping force. Clamping force is the one-sided linear force x 2, regardless of whether or not it is a slider or fixed caliper. The above is paraphrasing my friend James Walker Jr. He wrote an excellent book titled, "[ame="http://www.amazon.com/High-Performance-Brake-Systems-James-Walker/dp/1613250541/ref=sr_1_fkmr2_3?ie=UTF8&qid=1405689625&sr=8-3-fkmr2&keywords=high+performance+brake+upgrade+book "]High Performance Brake Systems: Design, Selection, and Installation.[/ame]" I'd encourage anyone interested in this topic to buy it, read it, and then read it again. He used to work for Bosch designing ABS systems and is a brilliant engineer. I'll try to get some engineering time today to do the bias calculations. We're tied up working on our new 2015 WRX Big Brake Kit, but hopefully I can get some real numbers here next week. There are a lot of ideas flying around here, but I'll try to break down some of the basics in an understandable/simple way. One of the problems is that there are a million terms/jargon involved, and I see people in this thread saying the same things in different manners. If you're confused, don't feel bad, it's confusing sh*t!  I've been doing this every day for over 10 years and I still have to reread and rethink some of these concepts at times. Anyway... I've been doing this every day for over 10 years and I still have to reread and rethink some of these concepts at times. Anyway...As stated elsewhere in this thread, the primary goal of a big brake kit is to manage heat. Brakes don't stop the car, they turn the kinetic energy of a spinning disc into heat. They do this by generating friction between the pad and disc. Tires stop the car by generating friction with the road/track. If you can lock up your tires with your existing brakes, you have all the brake torque you need (people call this braking power, brake torque, brake force, brake output, leverage, etc.). Heat Management Big brake kits are all about heat. They manage the heat generated from the friction between the pad and disc and deal with it in a number of ways. Think of the heat as flowing through the system in a few ways:

Again, as the disc and pad generate friction, the energy of the spinning disc is converted to heat. The disc has to deal with that heat, but so do the pad and the caliper. That's why having proper race pads designed for high temperatures is critical for track use. The pads absorb heat and transfer it in similar ways to the discs. The pads radiate a massive amount of heat into the air around them. The pad backing plates are touching the pistons, so heat flows into the pistons. The pistons have brake fluid behind them, so the heat flows from the pistons directly into the fluid (why stainless steel pistons are a huge help, since they dramatically slow the heat flow). That's also why titanium pistons are used in high-end race calipers. As you can see, all of the features of a properly designed big brake kit are designed to deal with heat. That's what big brakes are all about, and why they are so useful. Brake Bias A big brake kit that is properly designed to fit on a particular automotive platform should include careful consideration of the OEM brake components that it is replacing. When we design a front BBK for a production vehicle, what we are trying to do is copy/mimic/mirror the OEM brake torque on a given axle as closely as possible. We are NOT trying to increase brake torque, provide more "stopping power," etc. Remember, brakes don't stop the car, tires do. Brakes just transfer spinning energy to heat energy. If the OEM torque output on a given axle is properly replicated, the big brake kit can be seamlessly integrated without any ill-effects to front-to-rear brake bias, ABS, etc. If the torque output created by the new brake components changes much from the factory setup, it can cause all sorts of issues (assuming the OEM master cylinder is left alone). So how do we mirror the OEM torque output on the front of the car? We carefully select the components for our kit while working towards the goal of superior heat management. The process goes like this: The first consideration is the disc. How big of a disc do we need for this vehicle? How much does the car weigh? How much power does it have? How much power could it have if our customers slaps a big turbo on it? What speeds will it reach on the track? How much tire can you cram under the fenders? On what tracks will our customers be running? How long will the sessions be that they're running? How big are the wheels that this car runs (we obviously need to fit behind them)? How much weight can we shave off vs. the OEM equipment (you only want enough thermal mass to get the job done. Anything beyond that is dead weight to drag around)? How thick can the disc be while still fitting a good number of popular wheels? What type of face groove/slot pattern does it need given the usage environment? All of the above questions point us towards a particular disc design. We look at things like disc diameter, total thermal mass, number of vanes, vane style, disc wall thickness, overall thickness, hat attachment style, etc. Again, what we're trying to do is provide a disc that will bring our intended customers all of the heat-management properties described above. So we've chosen our ideal disc specifications. Next we have to figure out the OEM brake torque. A LOT of effort by the car manufacturer goes into finding the proper brake bias for a given vehicle. This is where things get rather messy. Curb weight, drivetrain layout, center of gravity, wheelbase, static weight distribution, aerodynamic downforce, etc. all lead into a model of dynamic weight transfer under braking for a given vehicle. Once that is established, this data is combined with a bunch of data related to the tires, and a rather complex Anti-lock Brake System program is developed. I don't want to go too far afield on that topic, so lets assume the OEM engineers are doing a good job of finding the proper brake bias, and we want to copy it! Three things impact brake torque output on a given axle:

For the time being, lets ignore the pad mu by holding it as a constant. We look at the total OEM piston area and the OEM disc diameter. How much leverage, stopping power, brake torque, or whatever you want to call it, is our front brake system generating? Once we know that, we insert the disc we've chosen into the mix, and then choose a caliper to mate properly with it. If we are taking the disc diameter from an OEM 290mm to our chosen 325mm, we need to compensate for that disc diameter increase by lowering the overall piston area to counteract that effective radius increase. To simplify, disc diameter up, caliper piston area down. One effectively cancels the other out. If you put on a larger disc diameter, and you also put on a caliper with a larger overall piston area, you're increasing the overall brake torque on that axle. That can cause the problems I posted in my earlier response. With too much torque output on the front, the rear brakes aren't doing their share of the work. You want all four corners of the car simultaneously generating their maximum deceleration. If you don't have that, stopping distances will actually increase (further distance required to stop the car). Someone else mentioned it earlier in the thread, but an overall larger piston area also requires more brake fluid displacement, and can give you a long brake pedal as well with all else held equal. Everything above holds true for the rear brakes as well, except messing with the amount of rear brake bias can become downright dangerous. In a system with too much rear brake, the car can get extremely squirrely under braking. If the rear wheels lock up before for the fronts, that is an inherently unstable condition. The car can swap ends into a spin as the weight shifts forward under braking and the rear wheels lock. What about pads? Wouldn't putting a higher coefficient of friction (mu) pad in the front, but leaving the rear alone, increase the front brake torque. Yes it would. The magnitude of bias shift caused by pad mu is generally not as great as that caused by a significant increase in the disc diameter or piston area. If you go from a street pad with an average mu across its temperature range of .36 to a race pad with a .48 mu, it will have an impact, but not like increasing disc diameter two inches with all else held equal. Since the relative brake torque changes due to pad mu are fairly small, experienced racers/drivers play with pad changes to mildly alter brake bias. For example, someone in a car that typically understeers heavily might run a slightly more aggressive rear pad in an attempt to get the car to rotate under trail braking into a turn. I see this with WRX STI guys for example. Recap Hopefully you can see that brake upgrades aren't just about finding parts that will bolt onto a given car. There is a LOT of thought that goes into choosing the proper components that won't upset the car's overall dynamics. Throwing a bunch of improperly chosen brake components on a car frequently does more harm than good. I will say that in the majority of the situations where someone is pulling "bigger brakes" from a "bigger" platform (I'll call it the "Bigger is Better" Syndrome  ), the result is an over-amplified front brake setup. Most of the time they go for a larger diameter disc, but the overall piston area being run on that disc is also considerably larger as well. Over the years I've had a ton of phone calls from customers that begin with, "So I found a great deal on a set of Brembo's on eBay...." Then that customer explains that while their brakes look really cool, they actually perform like poo on the racetrack, cause all sorts of weird ABS issues, etc. Many times they also spend a good chunk of money fabricating, gathering, and scraping the bits and pieces to tie it all together. That also doesn't include the amount of time involved. For many people the time commitment to do all of that isn't actually feasible, and they'd rather just buy a professionally engineered, complete solution that shows up in a box the next day. ), the result is an over-amplified front brake setup. Most of the time they go for a larger diameter disc, but the overall piston area being run on that disc is also considerably larger as well. Over the years I've had a ton of phone calls from customers that begin with, "So I found a great deal on a set of Brembo's on eBay...." Then that customer explains that while their brakes look really cool, they actually perform like poo on the racetrack, cause all sorts of weird ABS issues, etc. Many times they also spend a good chunk of money fabricating, gathering, and scraping the bits and pieces to tie it all together. That also doesn't include the amount of time involved. For many people the time commitment to do all of that isn't actually feasible, and they'd rather just buy a professionally engineered, complete solution that shows up in a box the next day.All of that said, sometimes you get lucky!  There's absolutely nothing wrong with what the OP in this thread is doing if it is done right with some thought (which he's clearly trying to do). Sometimes the numbers all work out, disc diameter increases are offset by piston size changes, and everything closely approximates the OEM brake torque for a given axle. That is what the other folks in this thread are trying to find out. There's absolutely nothing wrong with what the OP in this thread is doing if it is done right with some thought (which he's clearly trying to do). Sometimes the numbers all work out, disc diameter increases are offset by piston size changes, and everything closely approximates the OEM brake torque for a given axle. That is what the other folks in this thread are trying to find out. Good level-headed discussion gents.  I'll try to have the numbers run soon. I'll try to have the numbers run soon.

__________________

Jeff Ritter|Mgr.- High Performance Division

Exclusive Importer AP Racing and Ferodo Racing www.essexparts.com  |

|

|

|

| The Following 16 Users Say Thank You to JRitt For This Useful Post: | ATL BRZ (07-22-2014), Bach415 (07-25-2014), BatStig (07-18-2014), Black Tire (07-19-2014), Calum (07-18-2014), DAEMANO (07-18-2014), Dave-ROR (07-19-2014), eikond (07-18-2014), eyedeez (07-18-2014), finch1750 (07-18-2014), Nhil (07-19-2014), SportInjected (07-18-2014), Sportsguy83 (07-20-2014), tbox (07-21-2014), The Slow One (07-18-2014), WRB5titch (07-18-2014) |

|

|

#78 |

|

NASA SpecE30 Racer

|

Done that twice on my SpecE30 racecar. Once the piston goes far enough through the backing plate the brake fluid exits the caliper body and then you finally realize there is a problem when you have no brakes.

__________________

- King Tut

Street/Track Car: 2006 Honda S2000 TT3 || Race Car: 1987 BMW 325is SpecE30 || Tow Vehicle: 2014 RAM 1500 EcoDiesel Sold Cars: 2012 BMW M3 || 2013 Subaru BRZ || 2012 Porsche Cayman R || 2009 Chevrolet Z06 || 2009 BMW M3 || 2004 BMW M3 || 2004 Nissan 350Z |

|

|

|

|

|

#79 |

|

Senior Member

Join Date: Aug 2012

Drives: 2014 SWP Limited BRZ

Location: Seattle, WA

Posts: 290

Thanks: 118

Thanked 113 Times in 69 Posts

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

|

Awesome!

__________________

|

|

|

|

|

|

#80 |

|

Thanks Jeff for clearing some things up!

- Andy |

|

|

|

|

|

|

#81 |

|

Senior Member

Join Date: Jul 2012

Drives: 2013 Asphalt FR-S Manual

Location: Whitby, ON, Canada

Posts: 6,716

Thanks: 7,875

Thanked 3,353 Times in 2,134 Posts

Mentioned: 99 Post(s)

Tagged: 1 Thread(s)

|

A sliding caliper has to move the piston(s) twice as far as a fixed caliper does, that's why for the same pedal pressure you get the same effective pad pressure either way.

Pressure at the pad is determined by piston area and how much fluid is being forced in by the master cylinder. A fixed caliper has twice the area but moves half as much, a sliding caliper has 1/2 the area but moves twice as much.

__________________

Light travels faster than sound, so people may appear to be bright until you hear them speak... flickr |

|

|

|

|

|

#82 | |

|

Wish Nissan made one

Join Date: Feb 2012

Drives: '13 WRB BRZ Premium

Location: Lake Orion, MI

Posts: 886

Thanks: 129

Thanked 360 Times in 189 Posts

Mentioned: 18 Post(s)

Tagged: 1 Thread(s)

|

Quote:

Any chance you found some time to check the math on the bias? Based on my research above and that online calculator, it appears that the Z32 calipers/Leg GT rotors combo changes bias slightly to the front (70.9 vs. 69.7%). The variables I wasn't sure about were the pad heights. If the above is correct, then I would think the experts would find that the brake bias is close enough to stock to consider this a successful brake upgrade. Care to comment on that (as you are the expert I'm referring to.. lol). In fact, I was playing with the pad coefficients and found that you can run a Winmax W2 in front and W3 in back and it nearly perfects it to OEM standards.. Same thing with W3/W4, W4/W5, W5/W6. So running a slightly more aggressive rear pad can move the bias backwards a bit more and get it even closer to OEM. Last edited by eikond; 07-21-2014 at 10:34 AM. |

|

|

|

|

|

|

#83 |

|

StreetKart

Join Date: Jul 2013

Drives: 2014 Scion FR-S Monogram

Location: Upstate, SC

Posts: 477

Thanks: 43

Thanked 180 Times in 111 Posts

Mentioned: 10 Post(s)

Tagged: 1 Thread(s)

|

so basically what we've discovered is that this "upgrade" is basically stock performance with a few more laps until you cook the pads?

__________________

TRD|Verus Engineering|Titan7|DEZOD Motorsports|JDL Auto Design

|

|

|

|

|

|

#84 | |

|

Wish Nissan made one

Join Date: Feb 2012

Drives: '13 WRB BRZ Premium

Location: Lake Orion, MI

Posts: 886

Thanks: 129

Thanked 360 Times in 189 Posts

Mentioned: 18 Post(s)

Tagged: 1 Thread(s)

|

Quote:

I guess it depends on your definition of performance. If you are talking about brake bias (ie.. front vs. rear clamping power), then yes.. these are basically stock. Based on my calcs (waiting for a professional to corroborate) they keep the bias within about 1% of stock. If your definition of performance is clamping power.. then yes, these are similar to stock. Both setups have similar piston sizes and the same master cylinder, so they will press against the rotor with similar power.. Which is more than enough to lock up the rotors and engage ABS. So for those two areas, these brakes are very similar to stock. But the exact same thing can be said for the high end Big Brake Kits.. they all try to keep similar bias and similar overall clamping power to the OEM setup. However, there are a few major benefits to Big Brake Kits (that are mirrored to a lessor extent with these Z32 brakes). 1.) Light weight. These drop 8lbs on each side for the caliper. A blank OEM disk does add about 5 lbs back.. but you still have a net decrease in weight. A two-piece rotor would save even more if you want to spend the money on them. 2.) Better feel / consistency from fixed calipers: Quote from Wilwood's website - "fixed mount calipers that transfer PSI within the caliper into braking performance with a much higher efficiency are typically used on high-performance cars and for vehicles exclusively employed in racing for that purpose." 3.) Better heat dissipation: Having larger and thicker rotors will help disburse the heat. It might net you a few more laps if you are destined to overheat them.. Or, you might not overheat these brakes at all.. the larger heat-sink takes longer to heat up and more surface area allows for more cooling, so they might not ever overheat.. just depends on your usage. I would say that these three points make the $600 investment well worth it. But everyone has their own opinion of course. Oh.. and two more benefits just for fun: 4.) Cosmetics: These calipers look fantastic (especially after I shave the Nissan logo and put on the Subaru decal and paint them). The bigger rotors look great behind the wheel, and would look even better if you opted for drilled or slotted, etc.. For a big section of 86 owners.. the cosmetic improvement makes the whole thing worth it. 5.) Easy maintenance. Pad replacement is incredibly easy with these calipers since you don't have to remove them. You just slide out the pins and top clip and slip out the pads and put in the new ones.. easy! |

|

|

|

|

|

|

|

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Brake Pads, Rotors and All Your Brake/Suspension Needs! Great Prices!! Check it out!! | Mike@CZP | Brakes, Suspension, Chassis | 348 | 06-01-2018 12:29 PM |

| Project Mu - Brake Pads, Rotors and Brake Cooling Duct - FREE SHIPPING! | eauto | Brakes, Suspension, Chassis | 255 | 10-15-2014 01:45 PM |

| FS: FRS OEM E-Brake (Emergency Brake) Hand Brake Boot | CamryDS | Interior Parts (Incl. Lighting) | 0 | 06-24-2013 11:26 PM |

| Redline360: Brake Lines, Brake Rotors, Brake Pads for BRZ/FRS | Redline360 | Brakes, Suspension, Chassis | 12 | 01-05-2013 10:20 PM |

| Secondary Rear Brake Caliper for drifting or parking brake?? (pics) | Axel | Scion FR-S / Toyota 86 GT86 General Forum | 20 | 02-25-2010 10:28 AM |