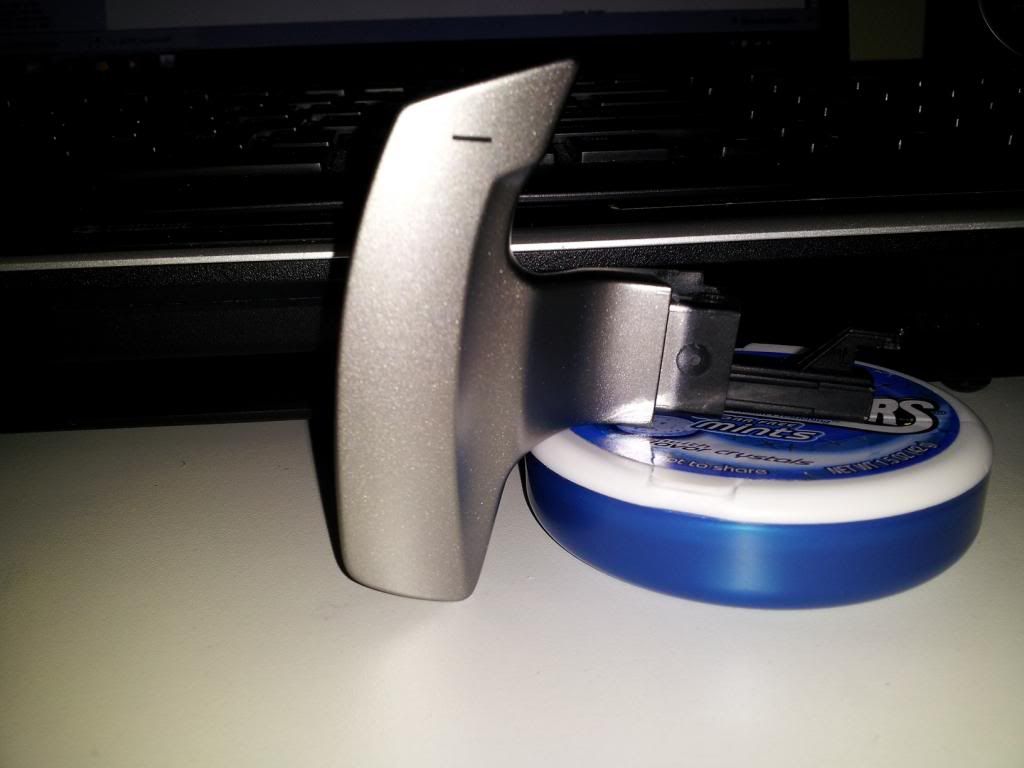

Sorry for the bad picture, but this is what the paddle shifter looks like disassembled

Just the paddle

There are a few things I noticed when playing with the shifter:

1. The paddle itself is a lot larger and more intricate than originally anticipated. Making the entire piece of billet aluminum will likely be too expensive for the average consumer

2. The spring binds and won't shift properly if the spring preload is changed

3. The spring seems to be a custom size and rate, so swapping springs may be difficult to do

4. The black box can be left alone if the paddle is swapped

So where does that leave us? There are a few options

The entire paddle can be made and you can replace the entire piece (either at home or by sending it to us) or we can design a paddle that slips over the existing paddle to act as an extension or we can make a simple stick-on piece. Personally, a slip on extension would be the easiest for end users and better looking, but this is really a choice up to you guys and gals. Would you still be interested in something like this?