Quote:

Originally Posted by GSpeed

Nice Al welding!

|

Thanks. By no means is it production worthy but it's satisfying to put two pieces together and build something yourself ^_^.

While we've been focusing most of our efforts on learning ANSYS SpaceClaim, Fluent, and their meshing software, the printer got some upgrades! I finally took some photos so figured I would share.

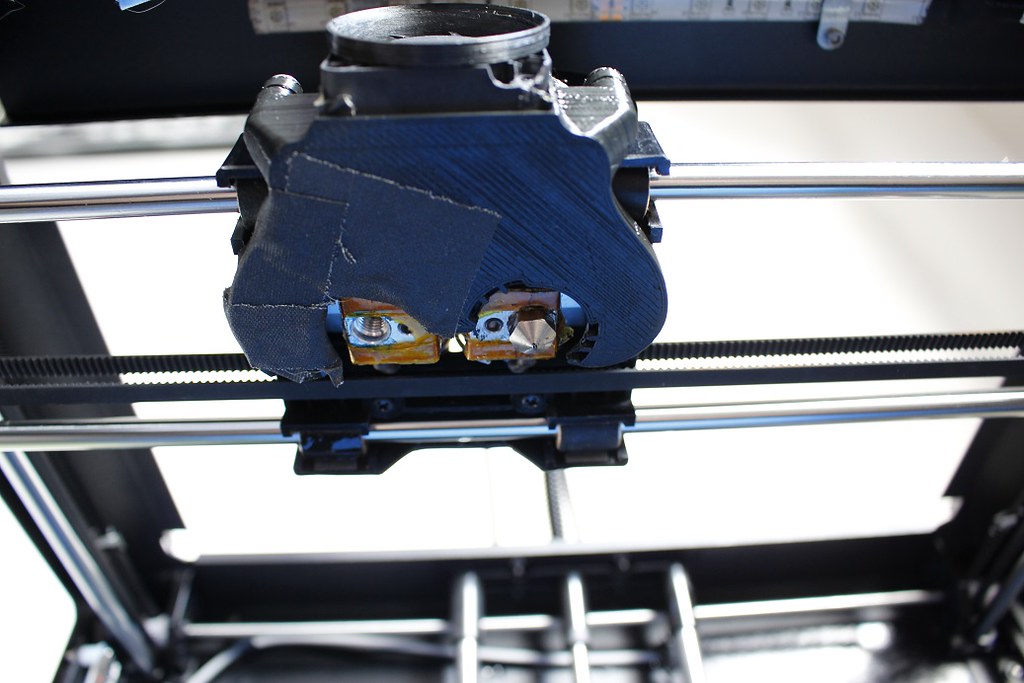

-Roller bearings were getting very very loud, so I went to some bronze sintered units which greatly reduced the noise and tightened up the movements a bit. It was primarily for noise and I can say it's a huge difference!

Before:

https://www.facebook.com/veloxmotors...0353579538084/

After:

https://www.facebook.com/veloxmotors...0353579538084/

-Printed out a Velox backing plate.

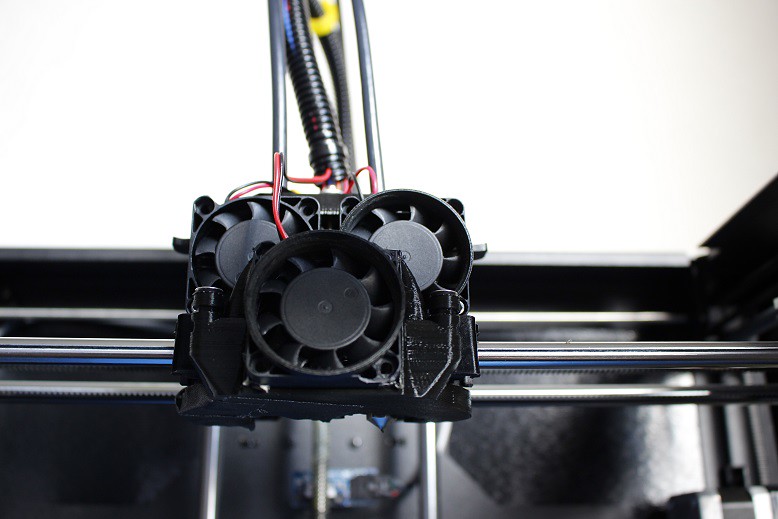

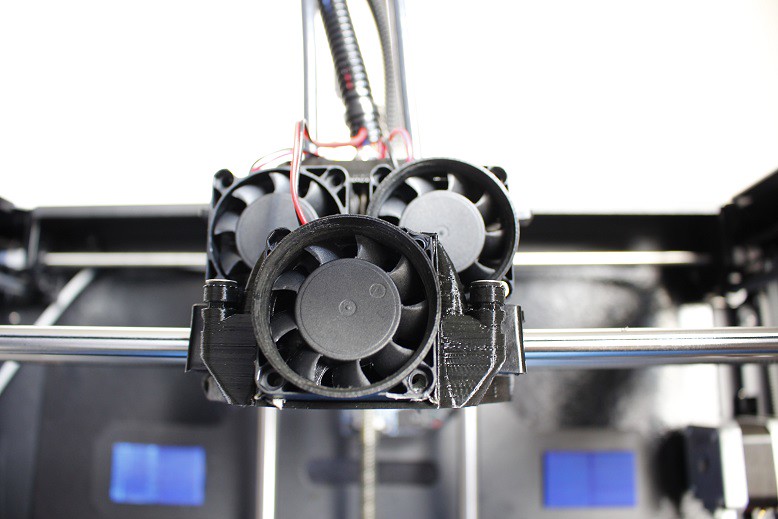

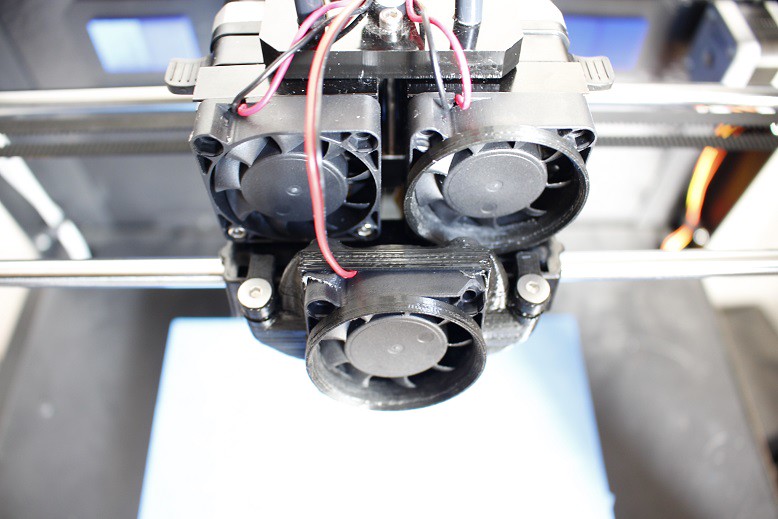

-I typically print with PLA, which likes to be cooled as it's printed, this is referred to as active cooling. Lucky for me, my printer is common so I was able to download a unit that bolts directly onto my printer and print it out. Tape is on the left half because I typically only use the right extruder and that increases flow to the right. Wired in a new fan, added a line of code to the slicer program, and we have active cooling!

-Finally, I saw the nasty tip clearance of the fans, so I drew up a press in velocity stack and now the printer is a certified race printer!

While Paul was in town for ANSYS training, we did some flow visualization testing. While we weren't able to do as much testing as we wanted, we gathered some information and it's pretty clear to say that flow is staying attached to the main diffuser surface and quite a bit of the up-turn radius at only moderate speeds.

I'll grab some more photos when I remove the diffuser as there was a neat vortex coming off the center exhaust cutout location. We'll probably attempt to re-test in this fashion when I get some more diff/suspension covers in as we think that will help flow even more. Interesting to test none-the-less and it's neat to see flow attachment similar to how our CFD analysis shows.

Thanks,

Eric