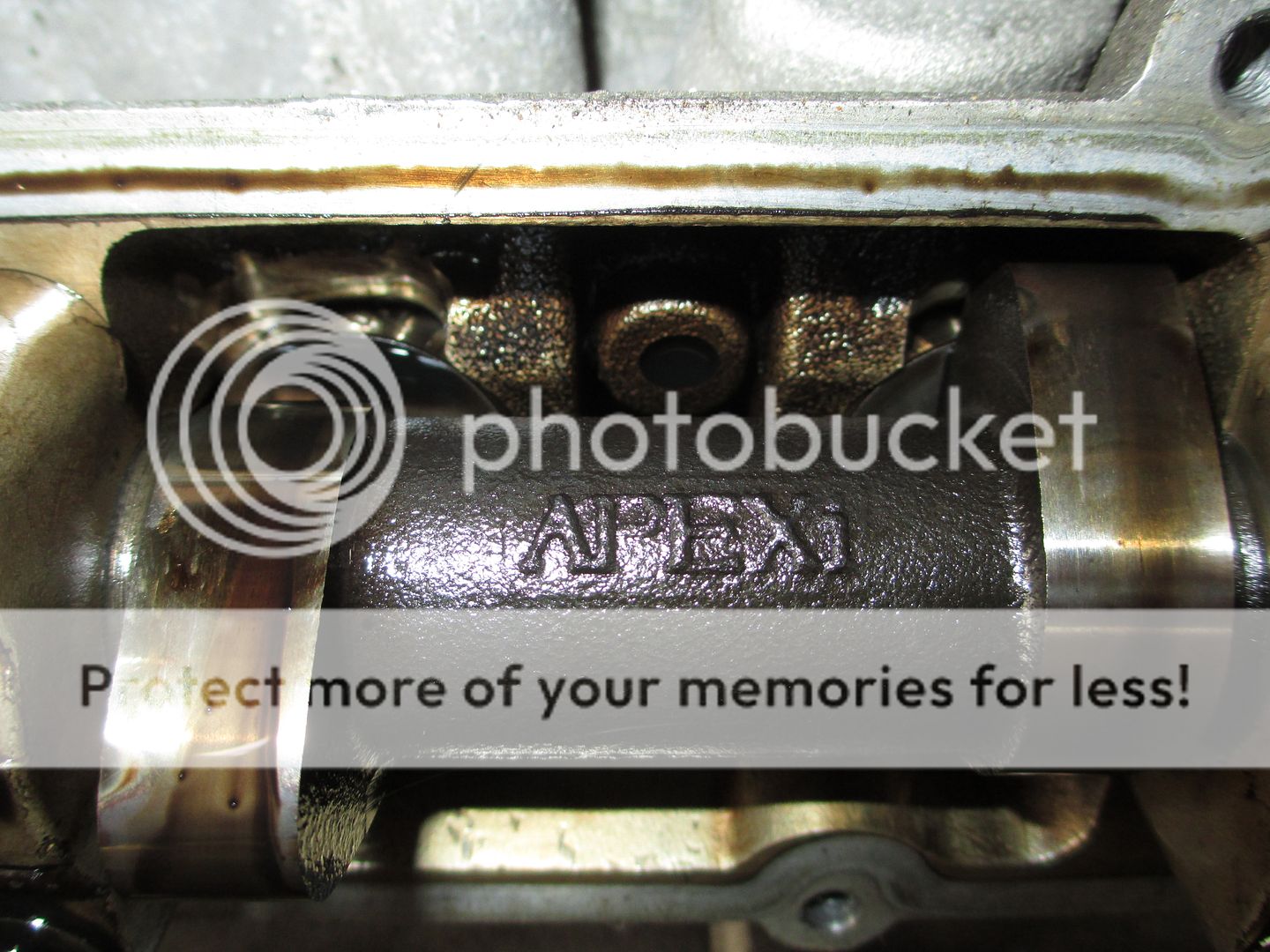

So they popped the valve covers off and it looks like there are some Apexi cams in there, hmm. It was held on with ARP head studs too, nice. Metal head gasket in there, of course.

Somebody did some intake port work too. They also cut out one quench pad and rounded off another. If I was doing a backyard rebuild myself I would consider myself lucky, scrub everything clean, check the deck and throw it back on, but I'm not. I find this to be a problem. I'm not going to use this head.

The engine overall was super nasty. Sitting so long without running left a lot of scale in the water jacket and it's just disconcerting to look at. I'm not getting a warm fuzzy. Again, if I was shadetreeing this thing myself, scrub it up and send it off to get the bores and deck checked. I'm not, though. I really don't want to use this block

Uh-oh. It's small, but there is a crack between the water jacket and a head bolt hole. It's not big at all and if this was a DIY build I'd probably still use it, but this is a some fucks given, but not very many build. This will not do. Part of me was like "fuck!" but most of me was like "hey, I had to buy a new one, the old one was cracked."

Yep, full retard protocols have just been initiated. This thing truly will be a "new" engine. I have sent out the call for price quotes on new castings.