Quote:

Originally Posted by tennisfreak

Looks awesome!

Waiting for @ stugray..........  |

Ok:

Quote:

Originally Posted by GrimmSpeed

Performance

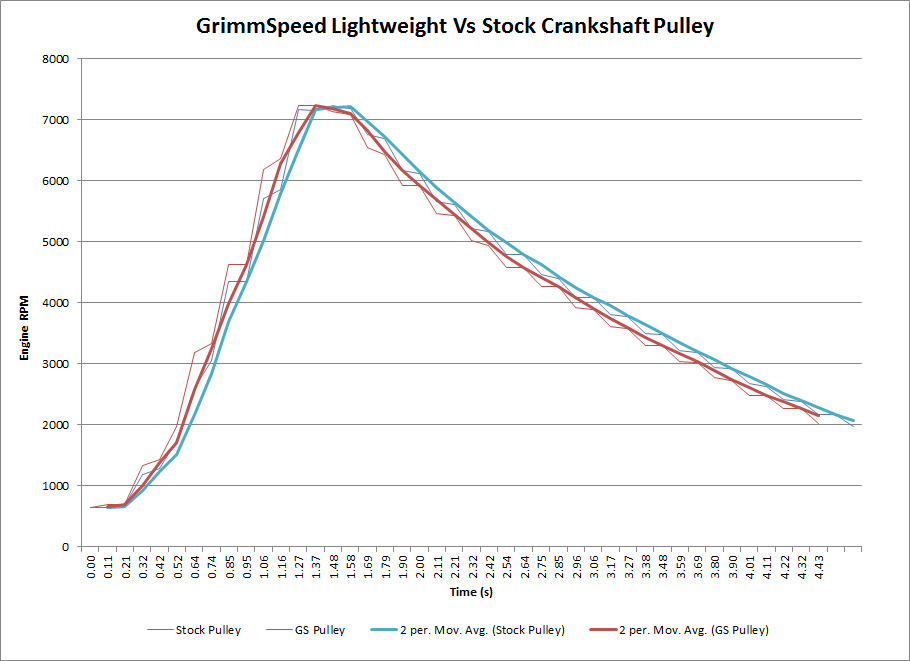

Proven performance from a crank pulley can be difficult to quantify, but when you're pulley is meticulously engineered, the results are there. Below is a chart showing the free revving of a stock BRZ equipped with a stock pulley and then a GrimmSpeed pulley. It's easy to see that the engine reaches redline faster and drops to idle faster with the GrimmSpeed Lightweight Crank Pulley installed. That's improved throttle response that you'll appreciate immediately.

|

"It's easy to see that the engine

reaches redline faster and drops to idle faster with the GrimmSpeed Lightweight Crank Pulley installed"

Umm. NO.

If you look closely at the graph, the rise & fall of RPMs is exactly the same.

The two graphs are only

offset ,because they started at slightly different initial conditions.

The

SLOPE of the RPM rise falloff is exactly the same for both pulleys which means "no appreciable difference in rotational inertia".

Thank you for posting a graph that so perfectly makes my point.

AND: Mass Moment of inertia Stock

30.42 lbin^2 vs 6.09 lbin^2 for the GS pulley.

Great! SO what is the Mass Moment of inertia of the entire rotating mass?

Assuming that they actually calculated it correctly, see how the mass Moment of inertia of a 4.9lb pulley can be over 30 lbsin^2???

That's a factor of 6X for something so close to the center of rotation.

That means that the mass moment of inertia of the entire ~500 lb rotating mass could easily be in the 3000-10000 lbsin^2 range. (and that is being

generous since MOST of the weight of the rotating mas is a

LOT further away from the center of rotation than the pulley)

SO changing the pulley makes a whopping:

30.42 - 6.09 = 24.33 lbin^2 in an engine with greater than 3000 lbs in^2?

For a whopping 24.33 / 3000

< 1 % difference? (actually MUCH less as the 3000 is VERY conservative)

Whoo Hoo! I'm sure you can feel that in the butt dyno.

As I have stated before: you will get a bigger benefit by changing the pressure plate bolts from steel to titanium or shed 1 ounce from the timing chains.

Grimmspeed: I apologize. I would not go out of my way to make this type of statement if I had not been called out to do so.

I still think the pulleys look awesome.

If I was building an engine from the ground up I would use these.