Quote:

Originally Posted by Kodename47

So is a higher % of PI at the very top end beneficial and allows you to run more timing? If you're running boost and aren't running as much timing, is more DI better at controlling knock? Discuss.....

|

We know the DI start of injection, assuming those are reverse engineered correctly (the numbers really represent the physical degrees), but we don't know the PFI end of injection or the DI end of injection timing.

We don't know the combustion parameters at those speeds. We don't know the combustion speed, the combustion phasing, the combustion stability, etc.

We don't know the smoke & particulate emission, or the wall wetting.

I'll speculate anyway. As I've said before, this stuff was mapped on an engine dyno in mostly steady-state conditions. DI is pretty much always better for cooling the intake charge, but the problem is forming the mixture within a smaller crank angle window, especially with side injection like this.

Here's what I mean by that.

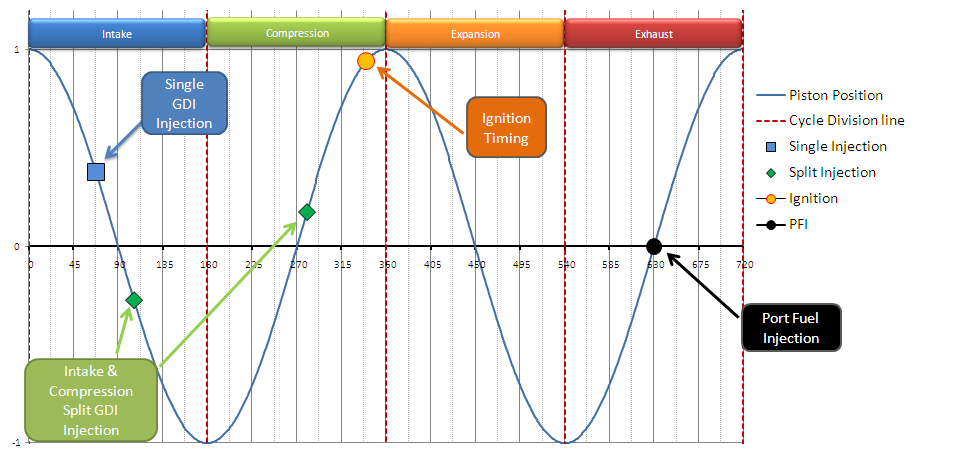

All you've got is part of the intake and compression stroke to spray the fuel with DI. That's why people are like "omfg duty cycle so low!!1! on DI engines" But if you spray during the expansion or exhaust stroke you are wasting the fuel, because it just leaves the engine unburned. With PFI, you can spray really the entire 720 degree cycle (100% duty). The mixture can vaporize in the intake port and doesn't rely on charge motion in the combustion chamber as much.

Now if you look at that above DI firing angle map, you can see it really ramping earlier and earlier at high speed, just as the PFI is coming on (higher number = earlier, and 360=TDC intake). Normally your SOI gets earlier to give more time for mixture formation to improve combustion stability, but also to limit how late the injection sprays in the cycle.

Well if I go too early I impinge the piston down causing smoke, and if I go too late I wet the liner causing oil dilution, at least on a side injection engine. At high speed though the pulsewidth is so long that you could be "trapped" and can't move the injection event later or earlier without impinging on something. That's where you dial in the port fuel. We can't see the end of injection timing for the PFI, but I suspect it is closed valve injection. So the port fuel has a long time to mix, helping combustion stability, and the charge cooling is done with the DI. Normally you can get a little charge cooling at high load with open valve PFI injection, but then you're throwing more liquid droplets into the cylinder that don't vaporize as well.

Personally, if you want the most power I recommend you run as much DI fueling as you can get away with, until the high pressure fuel pump can't flow anymore. This is due to the knock benefit. Most people on this subforum don't care about oil change intervals and particulate emissions.

Summary:

DI= more knock relief, potentially poorer mixture formation, more impingement on the piston and cylinder walls, flow limited due to injector flow rate and high pressure fuel pump flow capacity

PFI= more knock prone, more likely to form a more homogenuous mixture with better combustion stability, easier to flow at higher rates (just buy aftermarket PFI injectors and low side pump), not nearly as sensitive to fuel pressure or injection timing