Quote:

Originally Posted by plucas

A radius is not required for a splitter.

|

That's why you don't generally see radiuses on the splitters sold to amateurs/hobbyists.

Quote:

Originally Posted by plucas

To do it right, it would be an airfoil shape and continue far back. However, this is not economical as it would probably cost $1000+ to make.

|

I like your thinking, and when I was still considering every imaginable possibility, I took a hard look at that wild idea for a moment, but a number of show-stopping impracticalities scotched it immediately (e.g., drag, really low bang for the much-higher-than-$1K buck, raised ride height yielding even more drag). PITA-wise, I was not unhappy to skip that exercise.

If I couldn't get enough front aero on a car, I'd just hang a $150 sprint car front wing off the front of it. At least until NASA banned it anyway.

Quote:

Originally Posted by plucas

A sharp leading edge isn't always a bad thing.

|

Absolutely - it's still a splitter. While it yields less downforce, which is the purpose of the exercise, it does take up less space, so that's something at least. Plus, most off-the-shelf units come that way.

Quote:

Originally Posted by plucas

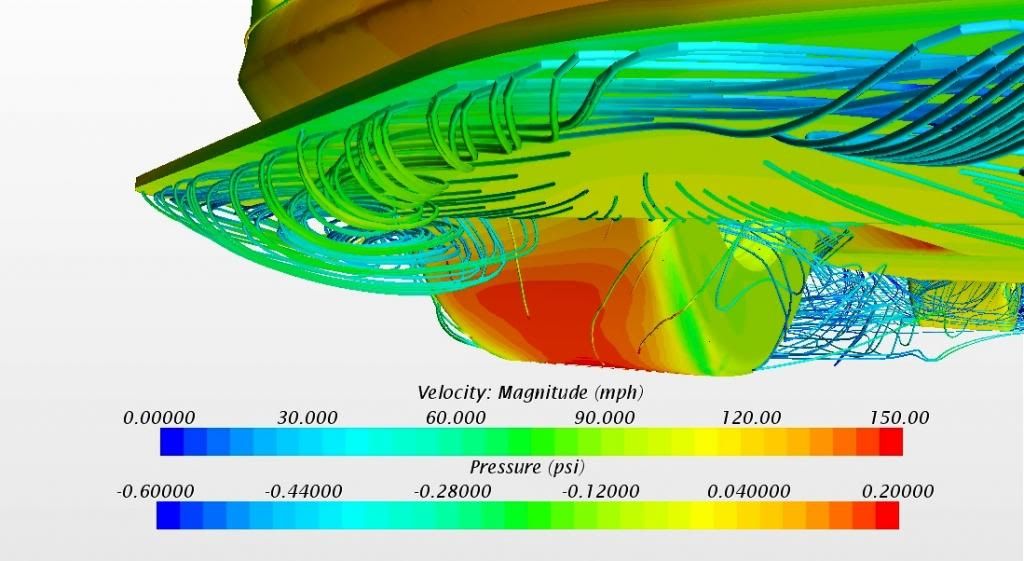

Sharp edges can create vortices. Vortices can be used to create downforce as shown below.

That vortex above created a lot of downforce across the splitter. |

I'm confused. Are you suggesting that a thin splitter with no meaningful radius on its leading edge is the means to maximizing splitter-generated downforce? That is, slowing down the air passing across the bottom of the splitter by allowing it to separate from the splitter surface, or not attach in the first place, will lead to the splitter producing more downforce?