|

||||||

| Forced Induction Turbo, Supercharger, Methanol, Nitrous |

|

|

|

Thread Tools | Search this Thread |

|

|

#29 |

|

Member

Join Date: Apr 2018

Drives: 2018 Subaru BRZ tS

Location: Napa, CA

Posts: 77

Thanks: 3

Thanked 40 Times in 30 Posts

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

|

Good Point - one more for the discussion. So using your rationale the turbo would be the better way to go.

I considered a turbo installation, as it is by nature more efficient. Reasons why I did not pursue it were for me that there was only one kit that was CARB compliant, in that case the gains did not seem worth the investment, there always seems to be heat issues with all turbo installations, and the kits do not seem to be up to level of a factory turbo'ed car which seems more mature technology wise. Also wanted a more uniform addition of power across the entire operating spectrum. If you use larger turbo for more grunt down low, you better make sure that you have a really good waste gate when you higher in the rev range. I have owned two turbocharged cars, a 1982 Porsche 924 Turbo, and a 2013 Mini Cooper Clubman S. Operationally they were both transparent as to the effects of the boost. They were pretty much effective throughout the power band. When you have a full corporation behind those turbo installations you can do that. Maintenance wise there was no turbo problems with the Mini whatsoever. The 924 T liked to shit turboshaft seals, so as you would go down road it was as if you were like the local mosquito abatement vehicle. I guess if you use the fact that Edelbrock guarantees their installation on a new vehicle you can use their limit on boost as to what a stock build can take. They advertise 242 WHP & 186 ft/lbs on a 2014 BRZ. You can stop there if you want to be safe. Cosworth also set a limit on the output on a Stage 1 installation, for internal issues if I remember correctly. Of course Irace I know you know all this stuff since you probably researched your Harrop for a while before you purchased it. This is all just for the benefit of the OP |

|

|

|

|

|

#30 | ||

|

Senior Member

Join Date: Nov 2016

Drives: 2017 BRZ

Location: USA

Posts: 655

Thanks: 326

Thanked 258 Times in 177 Posts

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

|

Quote:

Quote:

|

||

|

|

|

|

|

#31 | |

|

Senior Member

Join Date: Mar 2017

Drives: Q5 + BRZ + M796

Location: Santa Rosa, CA

Posts: 7,884

Thanks: 5,668

Thanked 5,805 Times in 3,299 Posts

Mentioned: 70 Post(s)

Tagged: 0 Thread(s)

|

Quote:

High rpms should put more stress on the components, but maybe there is higher oil pressure at high rpms to manage the forces on the bearings, or more efficiency and less jerk at high rpms. Maybe there is better knock prevention. Maybe there is better fueling. I don't know. I can think of all types of reasons why low rpms seem to be a place where failures occur that have nothing to do with power down low, but could be low end power too. Do turbos fail more than SC of equal power levels?

__________________

My Build | K24 Turbo Swap | *K24T BRZ SOLD*

|

|

|

|

|

|

|

#32 |

|

Member

Join Date: Jun 2018

Drives: 2019 Toyota 86

Location: SF Bay Area

Posts: 65

Thanks: 8

Thanked 10 Times in 8 Posts

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

|

Does this mean even turbo kits marketed for stock engines could put the engine at severe risk of failure if the engine wasn't rebuilt with stronger components?

To me its counterintuitive that FI engine failures occur at lower rpms. Is there a reason why this occurs? |

|

|

|

|

|

#33 | |

|

Senior Member

Join Date: Mar 2017

Drives: Q5 + BRZ + M796

Location: Santa Rosa, CA

Posts: 7,884

Thanks: 5,668

Thanked 5,805 Times in 3,299 Posts

Mentioned: 70 Post(s)

Tagged: 0 Thread(s)

|

Quote:

The following are reasons why engines could fail, which would be compounded by adding more power over stock design: There is more jerk (change in force or acceleration) at lower speeds and rpms. There is less oil pressure too, so significant forces on a bearing then could lead to rub easier. There may be less flow or efficient flow of exhaust gases at low rpms, which could increase the chance of knock or detonation. There could be a change over in fueling from 4 to 8 injectors (I donít know) or closed to open mapping (I donít know) that could put the motor at risk during the transition. There could be lugging of the motor at low rpms, which causes strain; ie, going WOT in a high gear at low rpms. Traction plays into resistance which plays into transional forces, so traction changes at low speeds and low rpms under jerk could be problematic like having to overcome static forces of a drag race versus a rolling race.

__________________

My Build | K24 Turbo Swap | *K24T BRZ SOLD*

|

|

|

|

|

|

|

#34 | |||

|

Senior Member

Join Date: Nov 2016

Drives: 2017 BRZ

Location: USA

Posts: 655

Thanks: 326

Thanked 258 Times in 177 Posts

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

|

Quote:

Higher rpm does equal higher stress, but those forces are more likely to eat rod bearings or break rod bolts. Rod bending is a compression failure mode, more likely from either low rpm+high cylinder pressure or detonation/pre-ignition issues imo. Quote:

Quote:

IMO no it really just means be careful how you treat a car that isn't FI from the factory. |

|||

|

|

|

|

|

#35 |

|

Member

Join Date: Jun 2018

Drives: 2019 Toyota 86

Location: SF Bay Area

Posts: 65

Thanks: 8

Thanked 10 Times in 8 Posts

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

|

|

|

|

|

|

|

#36 | |

|

Senior Member

Join Date: Jul 2014

Drives: 2020 Hakone

Location: London, Ont

Posts: 69,845

Thanks: 61,656

Thanked 108,285 Times in 46,456 Posts

Mentioned: 2495 Post(s)

Tagged: 50 Thread(s)

|

Quote:

You could blow the engine with the car sitting at idle in your driveway or you could do 100 track days perfectly fine. Many guys track with no issues but it does increase the risk though. Even a fully built engine can blow so there is no sure way of going about it.

__________________

Racecar spelled backwards is Racecar, because Racecar.

|

|

|

|

|

|

|

#37 |

|

Senior Member

Join Date: Nov 2016

Drives: 2017 BRZ

Location: USA

Posts: 655

Thanks: 326

Thanked 258 Times in 177 Posts

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

|

I wouldn't ever expect 100% confidence against failure on the track with FI, but there are things that can be done to improve the odds like higher octane gas, avoiding extended hard use on exceptionally hot days, avoiding WOT at low rpm especially in higher gears, monitoring oil temperatures and backing off when they go up too much, etc. It's a matter of risk tolerance. If I could not stomach the cost of an engine build, I would play it safe and stay away from road courses or maybe go and soft pedal a few of them.

|

|

|

|

|

|

#38 |

|

pessimistic skeptic

Join Date: Apr 2016

Drives: '14 FR-S Monogram AT JRSC

Location: Upstate NY

Posts: 1,767

Thanks: 1,695

Thanked 1,035 Times in 684 Posts

Mentioned: 14 Post(s)

Tagged: 0 Thread(s)

|

Enough dabbling. Be conservative and intelligent about FI while doing it. It is fairly safe if you are not boosting like an idiot. If the engine still blows after all precautions, I will either fix it or replace the engine and boost again. FI is awesome. I can't imagine driving with stock engine again.

|

|

|

|

|

|

#39 | |

|

Senior Member

Join Date: Mar 2017

Drives: Q5 + BRZ + M796

Location: Santa Rosa, CA

Posts: 7,884

Thanks: 5,668

Thanked 5,805 Times in 3,299 Posts

Mentioned: 70 Post(s)

Tagged: 0 Thread(s)

|

Quote:

__________________

My Build | K24 Turbo Swap | *K24T BRZ SOLD*

|

|

|

|

|

|

|

#40 |

|

pessimistic skeptic

Join Date: Apr 2016

Drives: '14 FR-S Monogram AT JRSC

Location: Upstate NY

Posts: 1,767

Thanks: 1,695

Thanked 1,035 Times in 684 Posts

Mentioned: 14 Post(s)

Tagged: 0 Thread(s)

|

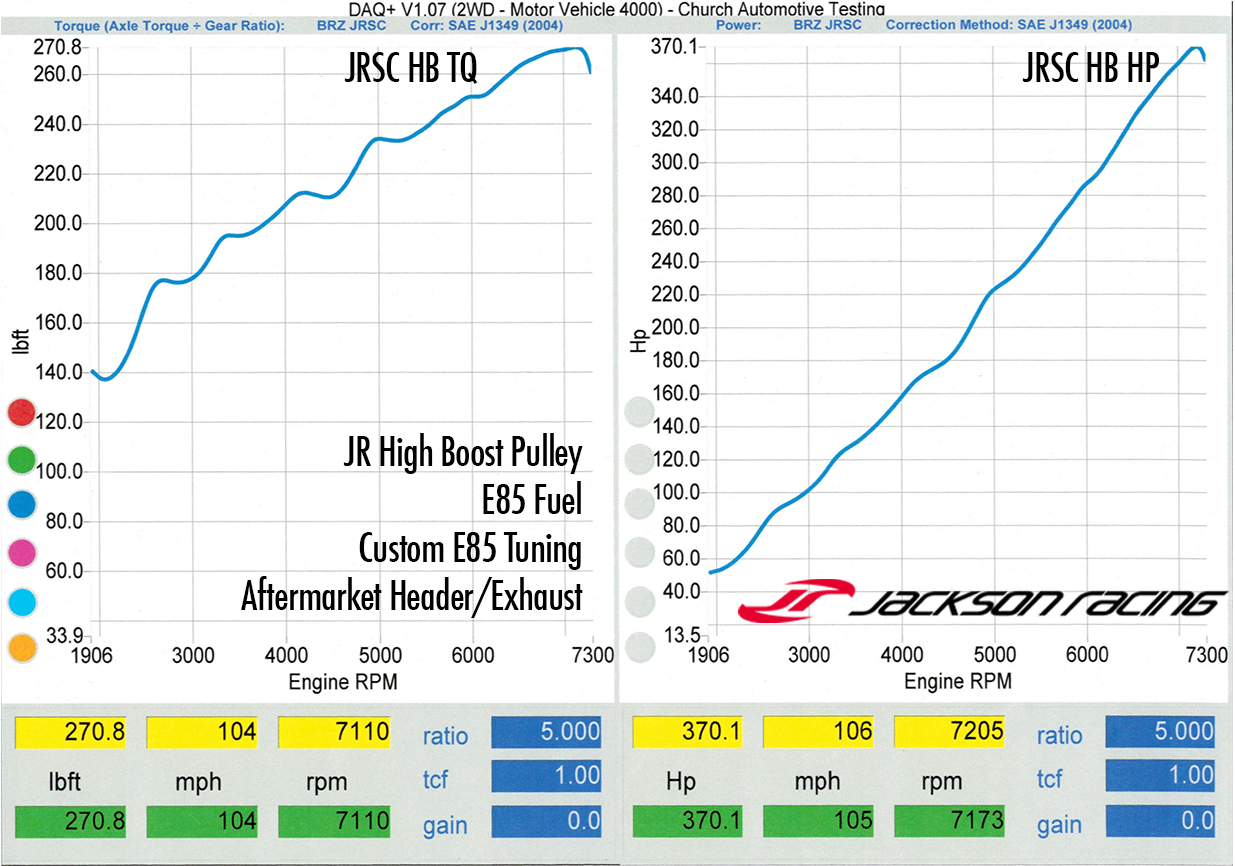

Looking at these curves

http://blog.vittuned.com/jackson-rac...ft-86-fr-sbrz/ Torque is rising but more like a sublinear curve, getting flatter at higher rpms. Power curve is almost linear |

|

|

|

|

|

#41 | |

|

Senior Member

Join Date: Mar 2017

Drives: Q5 + BRZ + M796

Location: Santa Rosa, CA

Posts: 7,884

Thanks: 5,668

Thanked 5,805 Times in 3,299 Posts

Mentioned: 70 Post(s)

Tagged: 0 Thread(s)

|

Quote:

__________________

My Build | K24 Turbo Swap | *K24T BRZ SOLD*

|

|

|

|

|

|

|

#42 |

|

pessimistic skeptic

Join Date: Apr 2016

Drives: '14 FR-S Monogram AT JRSC

Location: Upstate NY

Posts: 1,767

Thanks: 1,695

Thanked 1,035 Times in 684 Posts

Mentioned: 14 Post(s)

Tagged: 0 Thread(s)

|

Yes, those charts are with HBP (+E85+header). That is why higher rpm range torque is not flat anymore. And that is probably where engine reinforcements are now necessary. The link I have given above shows the same thing. See yellow dotted line (stock pulley) vs yellow continuous line (high-boost pulley)

Vittuned claims it is fine to use HBP with the stock engine in that link but I would not try myself or recommend anybody else. JR does not recommend without engine reinforcement either. |

|

|

|

|

|

|

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| WTB: blown engines | AVOturboworld | Want-To-Buy Requests | 1 | 02-15-2016 07:37 AM |

| Built engines | ActionJackson | Forced Induction | 7 | 05-28-2014 11:25 AM |

| VR6 engines... | dem00n | Other Vehicles & General Automotive Discussions | 29 | 01-25-2013 01:41 AM |

| 100 hp/l NA engines | einzlr | Other Vehicles & General Automotive Discussions | 95 | 11-15-2012 07:55 PM |

| So you think you know engines? | Ryephile | Other Vehicles & General Automotive Discussions | 43 | 02-04-2012 03:49 AM |