|

||||||

| Engine, Exhaust, Transmission Discuss the FR-S | 86 | BRZ engine, exhaust and drivetrain. |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

GrimmSpeed Lightweight Crank Pulley - New Product Information

*** Group Buy is currently active in the Group Buy forum. Please direct all pricing and Group Buy related posts to that particular thread and keep this one to a technical discussion. ***

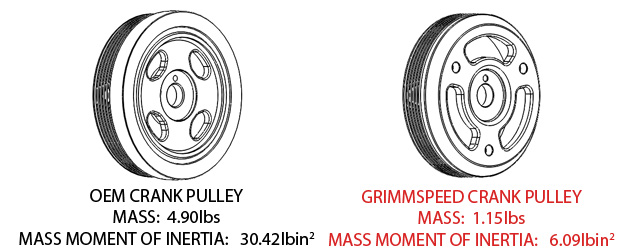

ENGINEERED PERFORMANCE.  [SIZE=3]Your factory crank pulley is responsible for transferring energy from your crankshaft to your water pump, a/c compressor and alternator. It does this by way of a rubber belt and it does it's job well. The drawback to the factory pulley is that it's quite heavy. Reasons for this include less expensive manufacturing and using the pulley's mass to smooth out 'noise' in the accessory system (NOT to be confused with functioning as a harmonic dampener, which it does not). The GrimmSpeed Lightweight Crank Pulley reduces the rotational mass of the system, allowing your engine to accelerate and decelerate the rotating assembly more quickly. Quick Specs

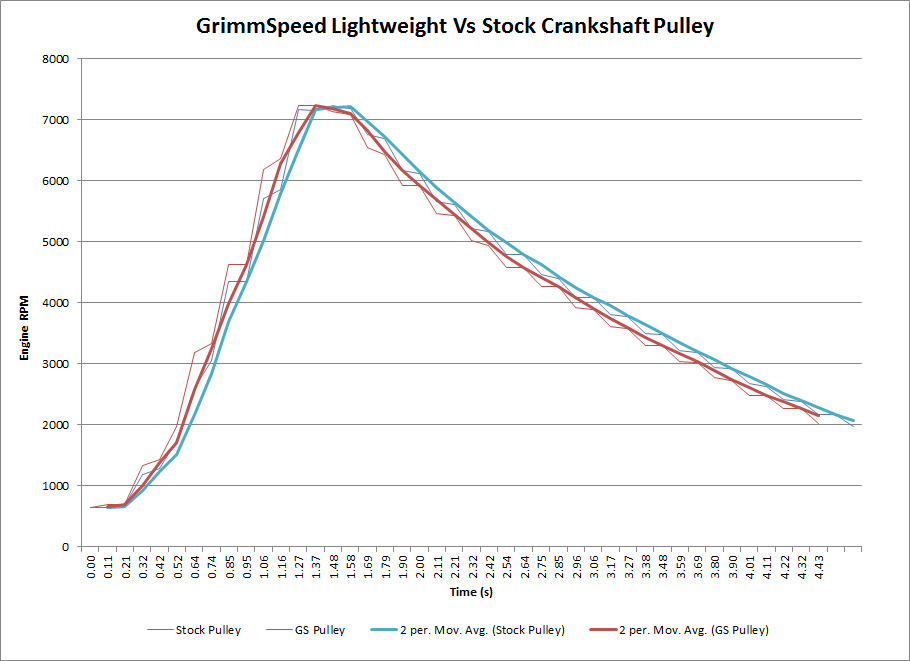

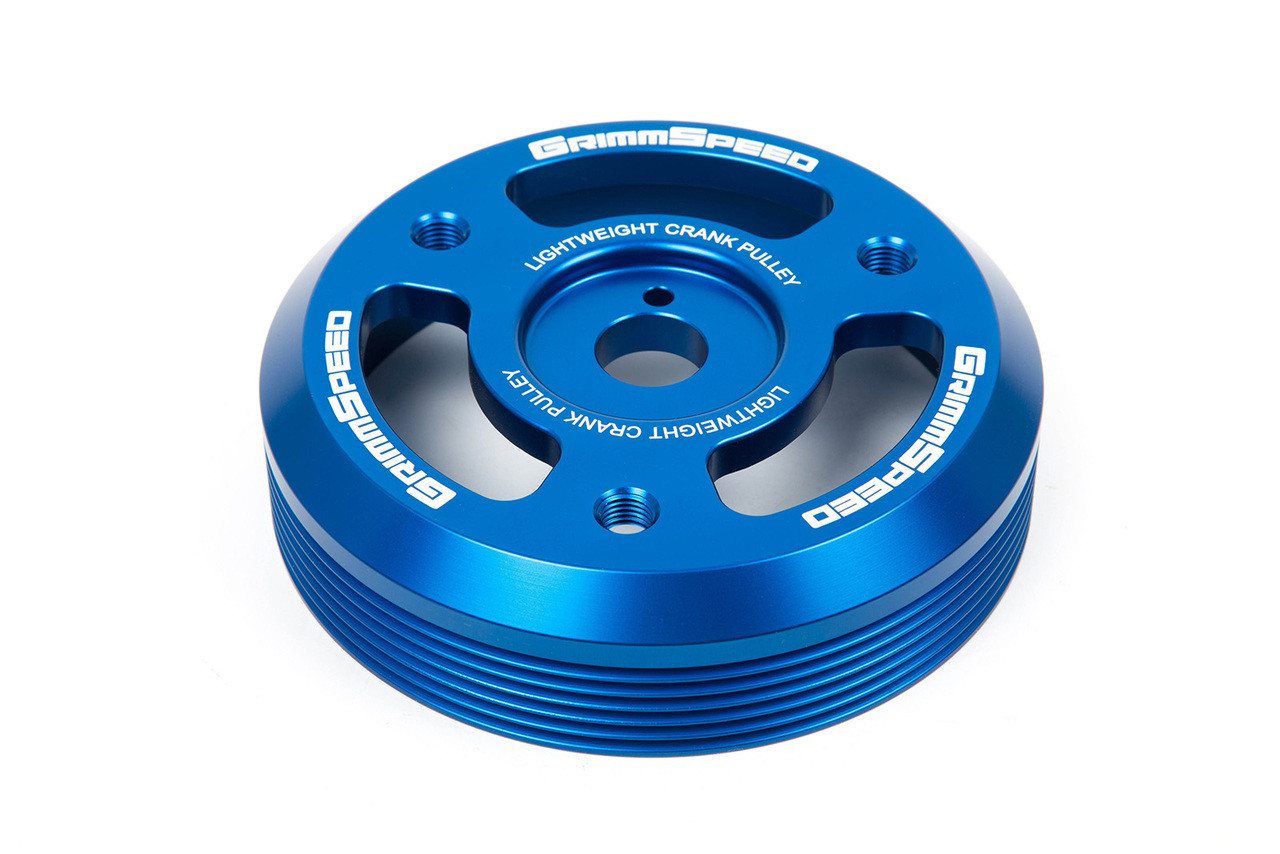

The design process for this pulley ensured that a perfect factory replacement fitment was maintained while performance was maximized. It's a common misconception that the mass of a crank pulley alone determines its effectiveness. The truth is that it's actually the moment of inertia that affects the pulley's ability to improve engine and throttle response. The moment of inertia, in non-engineering terms, is a function of not only the mass of an object, but how that mass is distributed about it's rotational axis. A lower moment of inertia means that less torque is required to spin the crank pulley and, in turn, the crankshaft/engine. Our engineers took great care to keep the already minimal mass as close to the center of the pulley as possible without sacrificing its strength. The result is a pulley that fits well, looks beautiful and works exactly as intended. From the first test drive, you'll notice smoother operation, faster response and a more enjoyable drive. Much of this is difficult to quantify, but you can see from the datalogs below that when compared to the OEM pulley, the GrimmSpeed Crank Pulley quantitatively improved throttle response.  Another major improvement made is that you'll find the necessary threaded holes to use our Crank Pulley Removal Tool for safe and easy installation and removal. On newer vehicles, cars can simply be put into a high gear to break the crank pulley bolt loose, but as with older chassis vehicles, this bolt will likely become quite stubborn with time. The use of the GrimmSpeed Removal Tool will make removal quick and easy. Materials Like any GrimmSpeed product, these pulleys are built to last. Using locally sourced 6061 T6 aluminum billet, the pulleys are machined and measured to verify critical dimensions before being anodized. The bright dip anodizing process that we use ensures a durable finish that will protect the pulley from corrosion. Lastly, each pulley is laser etched with a sharp GrimmSpeed logo. Performance Proven performance from a crank pulley can be difficult to quantify, but when you're pulley is meticulously engineered, the results are there. Below is a chart showing the free revving of a stock BRZ equipped with a stock pulley and then a GrimmSpeed pulley. It's easy to see that the engine reaches redline faster and drops to idle faster with the GrimmSpeed Lightweight Crank Pulley installed. That's improved throttle response that you'll appreciate immediately.  Fitment

Pulleys are available in Black, Blue, Red and our special release Gunmetal color.

Last edited by GrimmSpeed; 12-18-2014 at 12:56 PM. |

|

|

|

|

|

|

#3 | ||

|

Banned

Join Date: Sep 2013

Drives: 2013 GBS BRZ Limited

Location: Colorado

Posts: 1,925

Thanks: 627

Thanked 1,445 Times in 711 Posts

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

|

Quote:

Quote:

Umm. NO. If you look closely at the graph, the rise & fall of RPMs is exactly the same. The two graphs are only offset ,because they started at slightly different initial conditions. The SLOPE of the RPM rise falloff is exactly the same for both pulleys which means "no appreciable difference in rotational inertia". Thank you for posting a graph that so perfectly makes my point. AND: Mass Moment of inertia Stock 30.42 lbin^2 vs 6.09 lbin^2 for the GS pulley. Great! SO what is the Mass Moment of inertia of the entire rotating mass? Assuming that they actually calculated it correctly, see how the mass Moment of inertia of a 4.9lb pulley can be over 30 lbsin^2??? That's a factor of 6X for something so close to the center of rotation. That means that the mass moment of inertia of the entire ~500 lb rotating mass could easily be in the 3000-10000 lbsin^2 range. (and that is being generous since MOST of the weight of the rotating mas is a LOT further away from the center of rotation than the pulley) SO changing the pulley makes a whopping: 30.42 - 6.09 = 24.33 lbin^2 in an engine with greater than 3000 lbs in^2? For a whopping 24.33 / 3000 < 1 % difference? (actually MUCH less as the 3000 is VERY conservative) Whoo Hoo! I'm sure you can feel that in the butt dyno. As I have stated before: you will get a bigger benefit by changing the pressure plate bolts from steel to titanium or shed 1 ounce from the timing chains. Grimmspeed: I apologize. I would not go out of my way to make this type of statement if I had not been called out to do so. I still think the pulleys look awesome. If I was building an engine from the ground up I would use these. |

||

|

|

|

| The Following User Says Thank You to stugray For This Useful Post: | chas3wba0 (12-09-2014) |

|

|

#4 | |

|

Quote:

Quickly though, for what it's worth regarding the 'butt dyno', I can absolutely identify the difference that a crank pulley makes and I think that a lot of people would agree. That is the same type of commentary that we received when we released our strut tower bar with quantitative data that many argued was negligible. We sent a few of those people free bars with the agreement that they could send them back if they didn't want them or buy them if they wanted to keep them. Not a single person wanted to send theirs back. Matt Beenen Engineering |

||

|

|

|

|

|

#5 | |

|

Quote:

The testing was conducted the exact same way, and using an OFT to datalog. The OFT is good for about 10 samples a second, and all I did was log time, RPM, and throttle position. This is how I was able to obtain starting points, and using the average of three runs each specifically to prevent seeing results in the form of ONLY a data offset. I did the same for the decel chart (this are actually two charts added together), to make the time bouncing off the rev limiter negligible. So all the graph is intended to show is that at each instant in time (we'll use the acceleration side of the graph for discussion purposes right now) The Lightweight Pulley is at a higher RPM value than the stock pulley EXCEPT for idle, and redline, as you would expect. So again, the trendline used is a 2 period moving average, and was chosen ONLY to show a more smooth dataset as the actual datapoints can be hard to understand unless you know what you're looking for (which is rpm values at a given time). It is really hard to argue that the chart doesn't start at idle, and end at redline for both sets of data (no offset there), and that our pulley is always ahead of the stock pulley. We do both agree though that small changes in weight on the rotating assembly can make a difference. All we're doing here is showing the data that we recorded, showing a change. Sure shedding weight from the timing chain or changing the pressure plate bolts will have an effect too, and people can always pick and choose what they want to do. Me personally, I would probably do the substantially easier thing and just change the crank pulley if I were looking to shed weight. But also, it does look pretty cool, and that's one of the main reasons I'd put it on my motor too  No need to apologize when your questions and points are perfectly valid. We're simply presenting the data that we observed consistently and averaged. Speculation is fun, but testing is even more fun. So thank you! No need to apologize when your questions and points are perfectly valid. We're simply presenting the data that we observed consistently and averaged. Speculation is fun, but testing is even more fun. So thank you! Chase Engineering |

||

|

|

|

| The Following User Says Thank You to GrimmSpeed For This Useful Post: | chas3wba0 (12-09-2014) |

|

|

#6 |

|

Banned

Join Date: Sep 2013

Drives: 2013 GBS BRZ Limited

Location: Colorado

Posts: 1,925

Thanks: 627

Thanked 1,445 Times in 711 Posts

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

|

Maybe if I saw the raw dataset I could be convinced.

However I look at the graph (the thin lines or the Moving averages) the time rate of change (the slope) appears to be the same for both datasets. The moving averages seem to amplify this statement. The slopes of the averages are the same. Even the slopes of the thin lines appear to be identical with few exceptions. Even if you argue they are different, they are not "different enough" for a statistically significant difference. I would be interested for someone to actually calculate the rotational inertia of the various engine components. Coming up with a total number analytically would be very difficult. I think I could argue that removing grams from the perimeter of the starter teeth on the FW would make a bigger difference than 4 lbs from the pulley. Or grams from the alternator pulley since it spins at ~4-5 times the speed of the engine and the kinetic energy is proportional to the SQUARE of the rotation speed. So if the alt pulley rotates at 4X the crank speed, then a change in mass of the alt pulley would be 16X more effective than the same mass change in the drive pulley. (of course I am guessing at the drive multiplier) |

|

|

|

|

|

#7 |

|

Senior Member

Join Date: May 2014

Drives: 2017 BRZ

Location: Chicago

Posts: 3,285

Thanks: 1,256

Thanked 2,928 Times in 1,714 Posts

Mentioned: 58 Post(s)

Tagged: 0 Thread(s)

|

The slopes do start at a common 0,~700 and are different off idle, and in the transition into deceleration, both places I'd expect lower rotational mass to show up in such a log. Beyond that I have to agree, the rate of change is too similar for analysis by eye on a web optimized graph.

The net idle to redline to... Approaching idle still gains time, so this will benefit people that like to rev their favourite tune, too! The net idle to redline to... Approaching idle still gains time, so this will benefit people that like to rev their favourite tune, too! All kidding aside, if you are chasing every last bit of potential rotational energy, this should help. Sampling rate over the 12Hz offered by the OFT may be needed. (I think that's the right rate...) |

|

|

|

|

|

#8 | |

|

That Guy

Join Date: Dec 2011

Drives: 2013 asphalt FRS MT

Location: Halifax, Nova Scotia

Posts: 4,865

Thanks: 5,058

Thanked 2,867 Times in 1,499 Posts

Mentioned: 82 Post(s)

Tagged: 1 Thread(s)

|

Quote:

|

|

|

|

|

| The Following User Says Thank You to Calum For This Useful Post: | stugray (12-10-2014) |

|

|

#9 |

|

Senior Member

Join Date: Jul 2013

Drives: 2013 BRZ

Location: Norcal

Posts: 1,592

Thanks: 1

Thanked 623 Times in 378 Posts

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

|

What are your thoughts on the warnings and reports of failures from lightening both ends of the engine? I've gathered it seems OK to lighten one, or the other, but not both, something to do with harmonics and pounding bearings.

I ask because most people looking to lose weight are likely to get both lightened flywheel And lightened pulleys, and I' won'der if they might be setting themselves up for possible premature wear/failures. I don't know how much actual proof there is to these claims, but I know a lightened flywheel makes a MUCH bigger difference in rotational mass, throttle response, so much so that the lightened pulley improvements are negligable in comparison. |

|

|

|

|

|

#10 | |

|

Senior Member

Join Date: Nov 2013

Drives: 2015 Scion FR-S

Location: Santa Paula, CA

Posts: 301

Thanks: 179

Thanked 82 Times in 56 Posts

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

|

Quote:

It's a community-accepted fact that one or the other is okay, but not both. Most people opt to throw on a LWCP since it's so much easier to get to, but also because driving with a lightened flywheel is more tricky on the street, where 90% of people spend 100% of their time. |

|

|

|

|

|

|

#11 |

|

Airborne at your service

Join Date: Sep 2014

Drives: '17 BRZ Series.Yellow

Location: El Paso, Texas

Posts: 6,326

Thanks: 4,529

Thanked 5,587 Times in 2,929 Posts

Mentioned: 33 Post(s)

Tagged: 2 Thread(s)

|

Are you guys going to come out with a 5 piece pulley set like Raceseng's S2 kit?

|

|

|

|

|

|

#12 | ||||

|

Quote:

I know you're kidding too, but I would kill to have a substantially greater sampling rate for logging. Quote:

Quote:

At the end of the day I will always listen to the engine builders who have experience. If they're saying that a LWFW and LWCP are causing bearing wear issues I have no reason to believe they're lying, because what do they have to gain from that? Less engine rebuilds? :P Do I have the same first hand experience as these engine builders who have tore apart tons of motors and seen these exact issues? Nope, so I will listen to one who I trust. And like I said, Travisty75's last paragraph sums it up perfectly. Good on ya Quote:

Chase Engineering |

|||||

|

|

|

| The Following User Says Thank You to GrimmSpeed For This Useful Post: | Travisty75 (12-09-2014) |

|

|

#13 | |

|

Banned

Join Date: Sep 2013

Drives: 2013 GBS BRZ Limited

Location: Colorado

Posts: 1,925

Thanks: 627

Thanked 1,445 Times in 711 Posts

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

|

Quote:

I still believe that if you see or feel a 1% difference in the engine due to a pulley swap, then the new pulley has a 1% different drive ratio. How much would the radius of a pulley need to differ from stock to underdrive the system by 1%? (Answer - not perceptible with the naked eye). So IF I were to design a pulley such that the owner could "feel" a difference.... I would design the pulley to underdrive the system enough to see on a dyno, but the driven systems would not know the difference. (Wink Wink.... Nudge Nudge)

|

|

|

|

|

|

|

#14 |

|

Member

Join Date: Oct 2012

Drives: FR-S, 6MT, White

Location: Hartford County, CT

Posts: 63

Thanks: 6

Thanked 11 Times in 9 Posts

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

|

Regardless of how effective the mod is, I am pretty sure grimspeed is the first vendor on here to bother publishing (possibly even to bother calculating) moment of inertia. I think they deserve some credit for that.

GrimmSpeed I appreciate you not talking down to us. Side note: The sprintex 335 (or whatever) folks need an undersized crank pully. Last edited by Mechazawa; 12-10-2014 at 08:34 PM. |

|

|

|

|

|

|

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| GrimmSpeed Lightweight Crank Pulley - GROUP BUY | GrimmSpeed | Groupbuys | 105 | 02-16-2015 10:39 AM |

| Lightweight crank pulley | Vlady | Engine, Exhaust, Transmission | 112 | 01-09-2014 09:28 PM |

| Lightweight Crank Pulley | Vlady | Want-To-Buy Requests | 3 | 01-02-2014 11:31 AM |

| FS: Perrin lightweight crank pulley | tmccoy33 | Engine, Exhaust, Bolt-Ons | 1 | 09-12-2013 04:52 PM |

| Ralco RZ Lightweight Crank Pulley HELP! | JERZgrl88 | Engine, Exhaust, Transmission | 11 | 10-10-2012 12:41 PM |