|

|

#225 | |

|

Join Date: Jul 2012

Drives: S2000 CR

Location: Orange County

Posts: 14,528

Thanks: 8,917

Thanked 14,175 Times in 6,834 Posts

Mentioned: 966 Post(s)

Tagged: 14 Thread(s)

|

Quote:

I agree. That's where we started, and that's where we're staying. |

|

|

|

|

|

|

#226 |

|

Kuruma Otaku

Join Date: Dec 2009

Drives: Mk3 Supra with Semi-built 7MGTE

Location: Greater Vancouver (New West)

Posts: 6,854

Thanks: 2,398

Thanked 2,265 Times in 1,234 Posts

Mentioned: 78 Post(s)

Tagged: 2 Thread(s)

|

When you are getting dampers revalved, how specific can you get and what do the companies do? Can you graph out a target curve and have them try to match it, or just tell them general info like, for example, the springs will be x lbs/in stronger and you also want more low speed rebound?

__________________

Because titanium. |

|

|

|

| The Following User Says Thank You to Dimman For This Useful Post: | Calum (09-06-2013) |

|

|

#227 | |

|

Join Date: Jul 2012

Drives: S2000 CR

Location: Orange County

Posts: 14,528

Thanks: 8,917

Thanked 14,175 Times in 6,834 Posts

Mentioned: 966 Post(s)

Tagged: 14 Thread(s)

|

Quote:

For example, we have absolutely no problem releasing shock dynos for our (prototype) CSG-spec SRCs, because it's extremely unlikely that anyone can emulate/replicate the damping curves and still spend less money than what the CSG-spec SRCs cost. In other words, anyone with that talent charges enough for their time that it likely won't be copied. Also, when you're looking at that type of spring rate and damping, you want adjustability for different conditions, and vehicle changes. Lastly, the graphs only show part of the story. |

|

|

|

|

| The Following 2 Users Say Thank You to CSG Mike For This Useful Post: | Anthonytpt (09-07-2013), Dimman (09-06-2013) |

|

|

#228 |

|

That Guy

Join Date: Dec 2011

Drives: 2013 asphalt FRS MT

Location: Halifax, Nova Scotia

Posts: 4,865

Thanks: 5,058

Thanked 2,867 Times in 1,499 Posts

Mentioned: 82 Post(s)

Tagged: 1 Thread(s)

|

|

|

|

|

| The Following 3 Users Say Thank You to Calum For This Useful Post: |

|

|

#229 |

|

Senior Member

Join Date: May 2012

Drives: '13 BRZ Ltd

Location: PA

Posts: 458

Thanks: 265

Thanked 229 Times in 117 Posts

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

|

|

|

|

|

|

|

#230 |

|

Kuruma Otaku

Join Date: Dec 2009

Drives: Mk3 Supra with Semi-built 7MGTE

Location: Greater Vancouver (New West)

Posts: 6,854

Thanks: 2,398

Thanked 2,265 Times in 1,234 Posts

Mentioned: 78 Post(s)

Tagged: 2 Thread(s)

|

I'm assuming it's to say the curve doesn't solely indicate the quality of the shock. Rebound separator valves, shim and seal durability, mid valves to reduce shock 'lag', how it manages temperature/cavitation, body and shaft stiffness, etc... All factor in to the quality (and price, sigh...).

__________________

Because titanium. |

|

|

|

|

|

#231 |

|

dying bird under the hood

Join Date: Mar 2013

Drives: 2013 SWP Limited BRZ

Location: Disneyland, California

Posts: 1,331

Thanks: 546

Thanked 451 Times in 295 Posts

Mentioned: 34 Post(s)

Tagged: 0 Thread(s)

|

Just got back from my first auto cross, first run was 50 sec, then 44 sec then 41 sec, then consistent 39s and ended with 38, I had an issue with traction control where it would take the power from the car, so I tried turning it off and my times got slower because the rear just would not stay down, any suggestions to increasing rear grip to pass the 38 sec mark with tc on? I'm using tein flex and cusco LCA rpf1 17x9 with hankook v12 245/40/17, 2.1 camber all around.

__________________

|

|

|

|

|

|

#232 | |

|

Senior Member

Join Date: Dec 2012

Drives: FR-S Whiteout

Location: California

Posts: 2,863

Thanks: 1,808

Thanked 790 Times in 611 Posts

Mentioned: 42 Post(s)

Tagged: 0 Thread(s)

|

Quote:

From my experience with motorcycle suspension having gone through various different shocks and fork valves and various different set ups and combos, I learned that those pricy suspension components are honestly worth every penny that they cost. That is why I don't plan on going through the same thing with my 86 by getting "middle of the line" dampers just to regret the purchase down the road. I just don't want to waste the time and money experimenting with less than top notch stuff. But man.... Cars have 4 of these suckers rather than just 1 like a motorcycle..... 'Spensive dampers, Y U No Cheaper?!? Last edited by solidONE; 09-07-2013 at 08:03 PM. |

|

|

|

|

|

|

#233 | ||

|

Member

Join Date: Mar 2013

Drives: EVO

Location: Utah

Posts: 75

Thanks: 3

Thanked 49 Times in 26 Posts

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

|

Quote:

Quote:

I will say, I've seen 0.90 to 1.0 being quoted all over the internet on motion ratios for struts. I spent a good deal of time building a solid model of the EVO front suspension though and to my surprise, the average motion ratio was over 1. Hub spacers do mater, but only slightly because of the small angle changes. That said, even after you square it, you are talking about a ~10% error. Seems like most springs have about that much variance in rate anyway. While your analysis is analytically incorrect, assuming a 1:1 motion ratio gets you "close enough for the girls (you) go with." If that’s not good enough, then measuring it is the way to go. “HOW” you measure is also another issue though since technically, you would be interested in the center of pressure, and not the center of the actual tire. |

||

|

|

|

|

|

#234 | |

|

Kuruma Otaku

Join Date: Dec 2009

Drives: Mk3 Supra with Semi-built 7MGTE

Location: Greater Vancouver (New West)

Posts: 6,854

Thanks: 2,398

Thanked 2,265 Times in 1,234 Posts

Mentioned: 78 Post(s)

Tagged: 2 Thread(s)

|

Quote:

Are you talking about materials deflecting under load?

__________________

Because titanium. |

|

|

|

|

|

|

#235 |

|

Senior Member

Join Date: May 2011

Drives: '23 BRZ

Location: Providence, RI

Posts: 4,584

Thanks: 1,376

Thanked 3,890 Times in 2,032 Posts

Mentioned: 85 Post(s)

Tagged: 0 Thread(s)

|

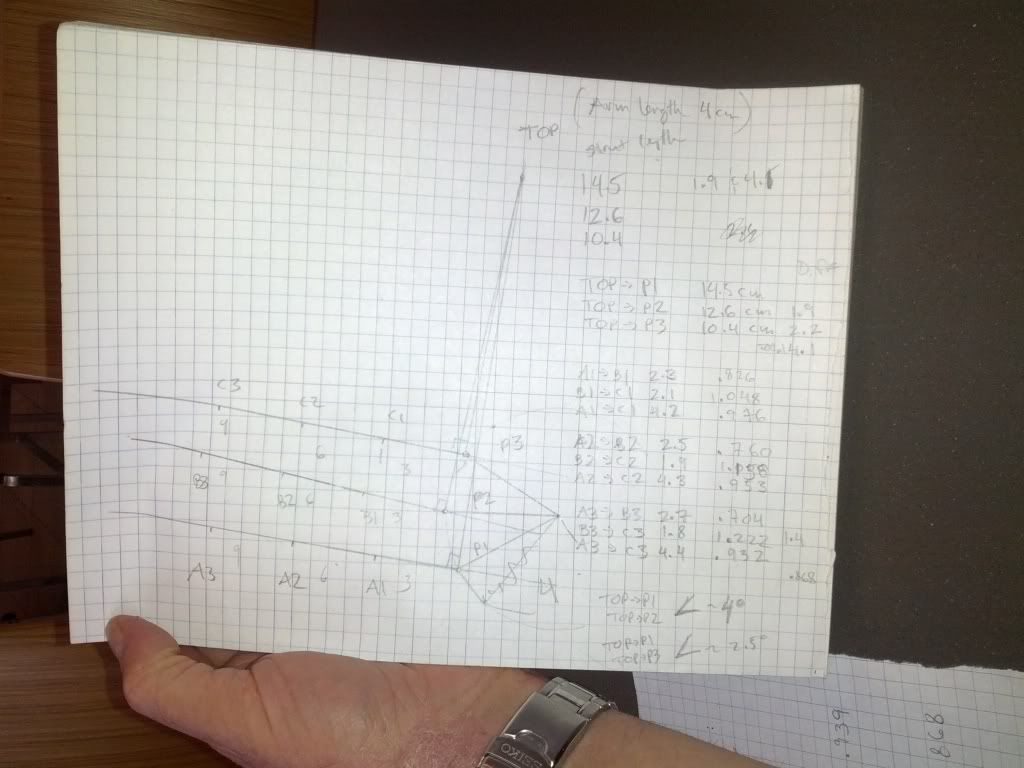

Unless the strut is infinitely long, it is rotating as the suspension compresses. This smallish rotation is why you will get a slightly different motion ratio, the further out the wheel is, the more this rotation moves it vertically. In the simple strut model I made, a 50mm increase in offset only resulted in a change in motion ratio from 0.95 to 0.93, so it's not a huge effect. 2% change in motion ratio => 4% change in wheel rate, though, so it is definitely worth taking into account.

|

|

|

|

|

|

#236 | |

|

Kuruma Otaku

Join Date: Dec 2009

Drives: Mk3 Supra with Semi-built 7MGTE

Location: Greater Vancouver (New West)

Posts: 6,854

Thanks: 2,398

Thanked 2,265 Times in 1,234 Posts

Mentioned: 78 Post(s)

Tagged: 2 Thread(s)

|

Quote:

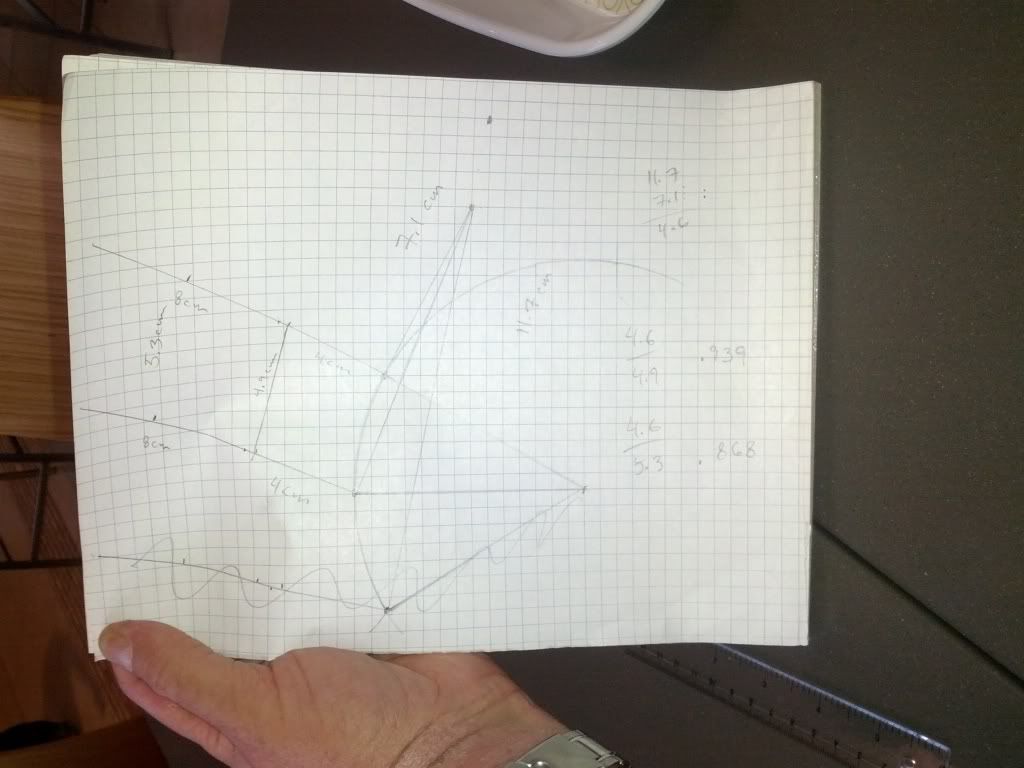

Edit: @ZDan This is how it works?  Edit 2: When a strut starts to lose camber the motion ratio starts to increase too? (These were done with a shitty dollar store geometry set, so all measurements are approximate...)

__________________

Because titanium. Last edited by Dimman; 09-07-2013 at 09:28 PM. Reason: edit x2 |

|

|

|

|

|

|

#237 | |

|

AutoX-10/10ths every run

Join Date: Jun 2012

Drives: 2013 Scion FR-S AT Firestorm

Location: San Marcos, CA, USA

Posts: 2,551

Thanks: 4,693

Thanked 1,838 Times in 1,000 Posts

Mentioned: 79 Post(s)

Tagged: 0 Thread(s)

|

Quote:

I drove the 1st 6 months of autocross in VSC sport. I was told over and over that it was slowing me down. I finally decided that I'd learn to drive with it off one day. Did 8 runs total that day. the 5th run I decided to try turning the TC back on to see how my times compared. I was over 1 sec slower. Hope this helps. Keep at it and have fun.

__________________

[ Delicioustuning | Counterspacegarage | RS-R USA | Cusco USA | SPL Parts | ACE Header | Stark Performance | Infinite Motion | Ciro Racing | Build thread:Here ] [ GR Corolla Core in White w/LSDs on wish list ] |

|

|

|

|

| The Following 3 Users Say Thank You to whataboutbob For This Useful Post: |

|

|

#238 | |

|

Senior Member

Join Date: May 2012

Drives: '13 BRZ Ltd

Location: PA

Posts: 458

Thanks: 265

Thanked 229 Times in 117 Posts

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

|

Quote:

. .I don't think we disagree - keep in mind, that illustration and post was specifically addressing whether or not wheel offset has any "leverage" affect on compressing the spring in a strut suspension. It was not intended to be a complete guide to motion ratio for a strut. Yes, angles will make a difference... most obvious is the SAI (not sure if you read the whole thread but that was discussed and accounted for), and as the strut swings out, a component of that should raise the wheel vertically (and that is not attributable to spring movement). But the point of that post was illustrating that wheel movement due to compression of the strut/spring will always be a 1:1 with the movement of the spring (or whatever the cosine relationship is due to SAI), regardless of offset (and forcewise exerts no leverage). But yeah, even if the reasons are wrong, most sources arrive at some value around 0.9ish or close to 1. And like you said, it's not a lot of error. Add to that the fact the most springs are only available in increments of 1k or 50 lb to begin with, so even if you are targeting some super-specific frequency (for whatever reason), the solution is already limited in resolution. |

|

|

|

|

|

|

|

|

|

| Thread Tools | Search this Thread |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Air Suspension Discussion Thread - Let's Get Nerdy | Andrew@ORT | Suspension | Chassis | Brakes -- Sponsored by 949 Racing | 174 | 02-13-2016 03:17 PM |

| RallySport Directs Everything Suspension thread!! | RallySport Direct | Brakes, Suspension, Chassis | 21 | 07-02-2014 05:31 PM |

| The OFFICIAL Ohlins Coilover Suspension thread - High End Competition Suspension | ModBargains.com | Suspension | Chassis | Brakes -- Sponsored by 949 Racing | 63 | 05-22-2013 08:15 AM |

| 2012 Team USA vs the 1992 Dream Team | ERZperformance | Off-Topic Lounge [WARNING: NO POLITICS] | 1 | 09-14-2012 06:19 PM |

| Team build thread; PROJECT.STH | trueno86power | Other Vehicles & General Automotive Discussions | 0 | 03-02-2010 10:13 AM |