|

||||||

| Forced Induction Turbo, Supercharger, Methanol, Nitrous |

|

|

|

Thread Tools | Search this Thread |

|

|

#15 |

|

Senior Member

Join Date: Oct 2012

Drives: 1996 ST204, Series 10 FR-S

Location: Calgary, Alberta

Posts: 247

Thanks: 88

Thanked 200 Times in 85 Posts

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

|

I made some new progress today. First, I greased the crap out of the rollers. I wanted to minimize the force I would need to press them out.

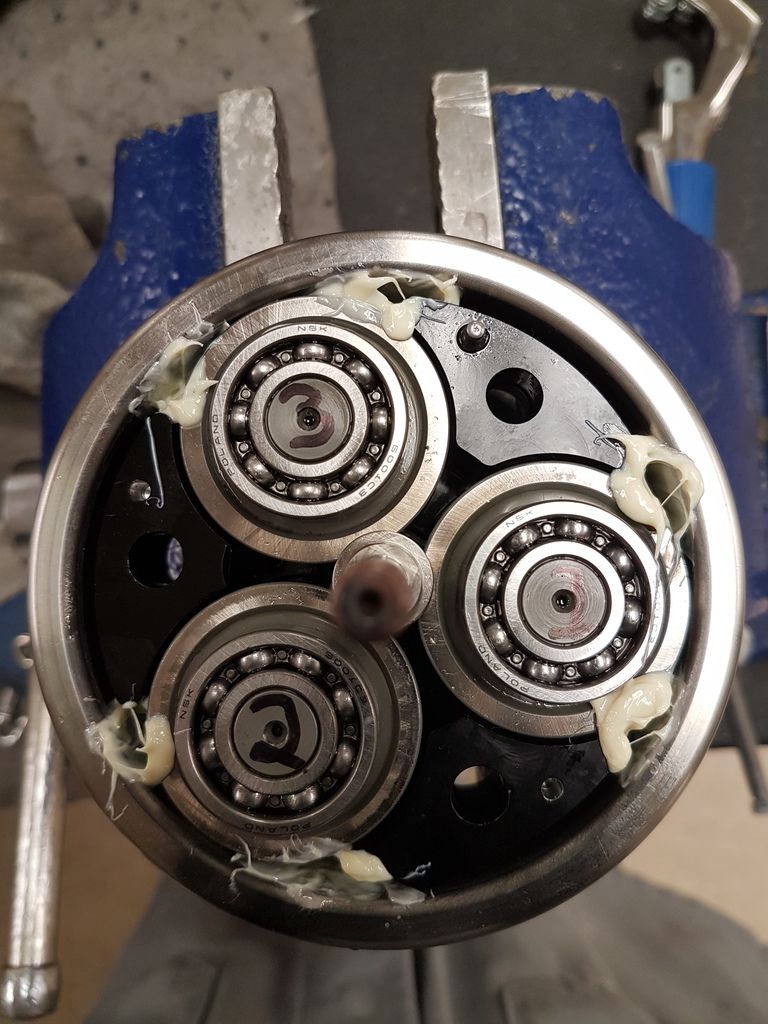

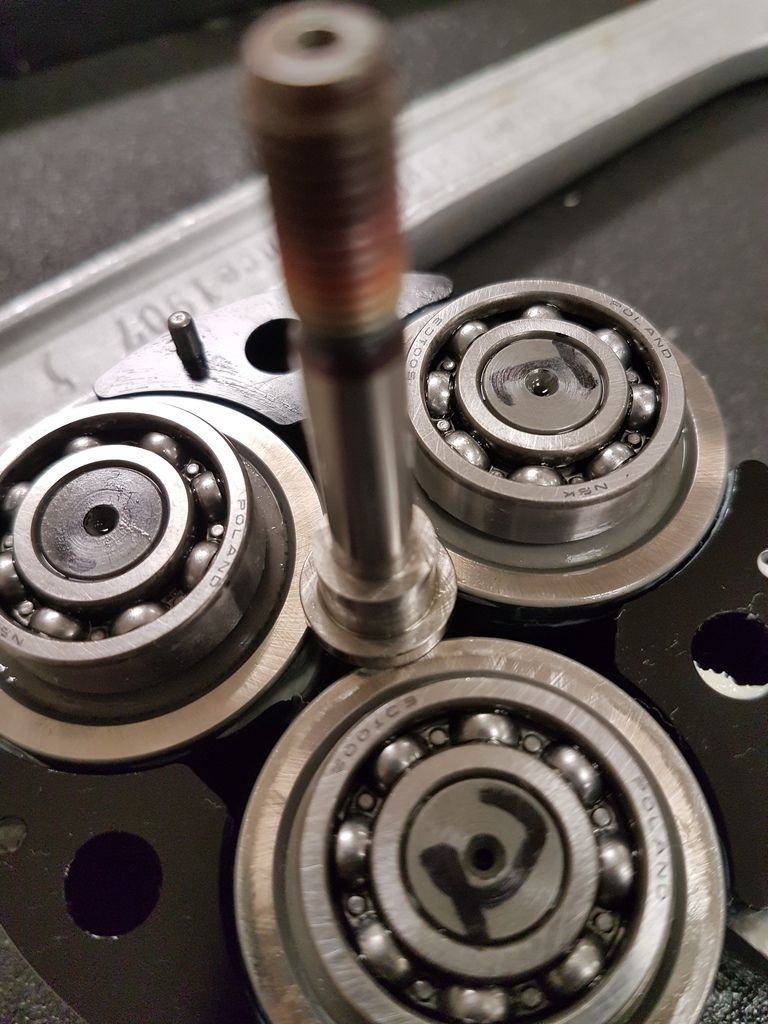

I then heated the ring as much as I could to expand it (notice I have two heat sources going at once). Then it was time to press the rollers out.  Two things to notice here. 1. The surface finish on the rollers are terrible. They should be smooth to reduce wear on the sunshaft. 2. My number 2 roller has more wear from the sunshaft collar compared to the rest.  The number 2 roller was also sitting in the recess which has some wear in the anodized coating. This one is a head scratchier.... My gut feeling is that this wear is caused by belt tension putting the most axial/thrust load on the top bearing. If not, it might be from a failed bearing causing the entire bearing to lock up sometimes and spin both inner + outer race. I will need to check this #2 roller and sunshaft very closely for any flat spots.  I'm not expert in this stuff. Maybe some mechanical engineers could chime in. Update: Writing and talking to myself really gets the thoughts going. Looking at how the belt is tensioned, it makes perfect sense why roller #2 is more worn. Load from the belt pushes roller number two towards the front and into where the wear in the anodization is seen.

Last edited by projek_01; 04-23-2019 at 01:31 PM. |

|

|

|

|

|

#16 | |

|

Senior Member

Join Date: Oct 2012

Drives: 1996 ST204, Series 10 FR-S

Location: Calgary, Alberta

Posts: 247

Thanks: 88

Thanked 200 Times in 85 Posts

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

|

Quote:

As for the new rebuild parts, they must be made locally. With the right lathe and knowledge, the parts (sunshaft and rollers) honestly don't seem very hard to reproduce. I am very tempted to sketch up the sunshaft in CAD and see how much it would cost to get a stronger one made. That would also involve enlarging the bore on the compressor which i'm unsure about. A blonde one off centre when enlarging the bore and it's going to wobble itself into crumbs. Also, I would personally upgrade those three internal fasteners to 10.9 strength and also use a dab of locktite. Mine weren't very tight when I took mine apart. |

|

|

|

|

|

|

#17 |

|

Senior Member

Join Date: Sep 2016

Drives: 2016 Series.HyperBlue BRZ

Location: Augusta, GA

Posts: 182

Thanks: 33

Thanked 50 Times in 41 Posts

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

|

Geez, where were you guys early February when I was searching high and low for parts/rebuilders. Thanks for satisfying my curiosity on what's inside a rotrex (real life not CAD)

|

|

|

|

|

|

#18 |

|

Senior Member

Join Date: Oct 2012

Drives: 1996 ST204, Series 10 FR-S

Location: Calgary, Alberta

Posts: 247

Thanks: 88

Thanked 200 Times in 85 Posts

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

|

I have concluded that the 6203 and 6003 bearing on my input side were likely causing my issues. There was some noticeable roughness just from spinning them in my hand.

Rotrex chose to use normal clearance instead of C3 clearance which are normally seen on automotive stuff. I looked at alternators, air conditioning pumps and they are all spec'ed with C3 bearings. Also, the output oil seal is a random size that no one makes. It is likely that I will have to get one custom made... very very annoying. |

|

|

|

|

|

#19 |

|

Member

Join Date: May 2017

Drives: frs

Location: mo

Posts: 77

Thanks: 2

Thanked 39 Times in 25 Posts

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

|

Please continue posting more info. This is good stuff!

|

|

|

|

|

|

#20 |

|

Senior Member

Join Date: Jun 2013

Drives: '13 BRZ

Location: CT

Posts: 485

Thanks: 314

Thanked 330 Times in 155 Posts

Mentioned: 6 Post(s)

Tagged: 1 Thread(s)

|

Those are the same type of bearings used in your standard bicycle crank.

|

|

|

|

| The Following User Says Thank You to tobin For This Useful Post: | projek_01 (03-27-2019) |

|

|

#21 | |

|

Senior Member

Join Date: Jul 2014

Drives: 14 BSP Edelbrock BRZ

Location: Lon Gisland

Posts: 806

Thanks: 113

Thanked 450 Times in 256 Posts

Mentioned: 12 Post(s)

Tagged: 0 Thread(s)

|

Quote:

|

|

|

|

|

|

|

#22 |

|

Senior Member

Join Date: Oct 2012

Drives: 1996 ST204, Series 10 FR-S

Location: Calgary, Alberta

Posts: 247

Thanks: 88

Thanked 200 Times in 85 Posts

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

|

Unfortunately, you cannot. The oiling system is designed to work with the unit clocked in that direction.

|

|

|

|

|

|

#23 |

|

Senior Member

Join Date: Oct 2012

Drives: 1996 ST204, Series 10 FR-S

Location: Calgary, Alberta

Posts: 247

Thanks: 88

Thanked 200 Times in 85 Posts

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

|

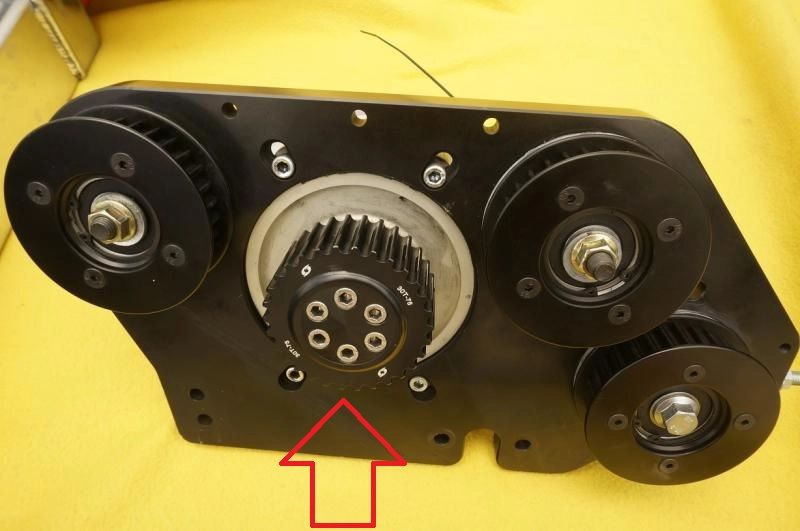

Some small updates today. Custom output shaft oil seal is on it's way. Made these 3D printed parts to hold the shaft in a vise so I can press the compressor back on. Going to pay some money to get the balance checked at a specialty turbo shop ($$$). Just for a piece of mind and good sleep at night.

|

|

|

|

| The Following 2 Users Say Thank You to projek_01 For This Useful Post: | Code Monkey (04-09-2019), Tristor (04-23-2019) |

|

|

#24 |

|

Senior Member

Join Date: Oct 2012

Drives: 1996 ST204, Series 10 FR-S

Location: Calgary, Alberta

Posts: 247

Thanks: 88

Thanked 200 Times in 85 Posts

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

|

I received a call last week from the turbo shop saying that the shaft broke when they were tightening the nut on the compressor wheel before balancing.

Normally, I'd be outraged and demand them to replace it at their cost. However, we all know that these shafts are underbuilt and snap all of the time. I got in touch with Mr. Jack Heath that built his own 600 whp Frankenstein C30-94 for his Honda S2000. He gave me some recommendations and his own sketch for an improved sun-shaft. This is going to cost me about $450CAD for materials, machining and heat-treating. This really hurts the pocket book but if all goes well, this should be a very reliable Rotrex for about $800 all said and done. Jack's version of the sun-shaft is made out of 440C stainless steel (Rockwell harness of 20) and will reach a hardness of about 60 after heat treatment. The shaft where the compressor is mounted on is 8mm wide compared to 7mm and a smoother radius was added to where it meets the oil seal area to improve strength. Therefore, my compressor will have to be bored to 8mm before balancing.  This is the shaft roughed out before hardening and final grind to size. If anyone want's the sketch, I can ask Jack for permission to forward it to you. Last edited by projek_01; 04-22-2019 at 07:36 PM. |

|

|

|

| The Following 5 Users Say Thank You to projek_01 For This Useful Post: | ChiTownFrs (04-10-2019), Code Monkey (04-09-2019), eherschend (04-10-2019), sroby (04-23-2019), Tristor (04-23-2019) |

|

|

#25 |

|

Senior Member

Join Date: Oct 2012

Drives: 1996 ST204, Series 10 FR-S

Location: Calgary, Alberta

Posts: 247

Thanks: 88

Thanked 200 Times in 85 Posts

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

|

The shaft is finally done and according to my Mitutoyo digital caliper, it is the correct size.

top: new bottom: POS Reassembly will happen in the coming week or so! |

|

|

|

| The Following 5 Users Say Thank You to projek_01 For This Useful Post: | Code Monkey (04-23-2019), CSG Mike (04-23-2019), Tristor (04-23-2019), Ultramaroon (04-22-2019), wparsons (05-03-2019) |

|

|

#26 |

|

Senior Member

Join Date: Feb 2018

Drives: 2017 Subaru BRZ Limited

Location: Denver, CO

Posts: 619

Thanks: 3,059

Thanked 595 Times in 300 Posts

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

|

This thread has some fantastic information, but it's also making me question my earlier decision in my build plan to eventually go FI with a Rotrex. Unfortunately, machining and fabrication are not my strong suits, therefore the level of work you've put into repairing and improving the unit is something that'd be out of reach for me to do myself. I'd love to see the community though make available parts, such as higher quality rollers/bearings, and improved/oversized sun shafts so it's a simple matter to get a local machine shop to bore out the housing and then the rest is mostly shop work I could do.

One of my primary motivations for considering a Rotrex based SC kit was for reliability, but now I'm thinking perhaps going the turbo route would be better with the appropriate tuning. Either way though, thanks for the wealth of information here. |

|

|

|

| The Following User Says Thank You to Tristor For This Useful Post: | sroby (04-23-2019) |

|

|

#27 |

|

Senior Member

Join Date: Oct 2012

Drives: 1996 ST204, Series 10 FR-S

Location: Calgary, Alberta

Posts: 247

Thanks: 88

Thanked 200 Times in 85 Posts

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

|

Interesting load of BS on their website.... There is definitely metal-metal contact in the traction drive system. It is basically ALL reliant on metal-metal contact.

@Tristor I truely hope that Rotrex has since made improvements to their design. If so, the unit can be indeed very reliable and make some decent power. Also keep in mind that people with broken units will post things online while happy owners usually don't. The actual failure percentage is like to be very skewed online. However, the fact that they left us early adopters stranded by not warrantying units/making people buy new units for 50% of MSRP left a sour taste in my mouth. I wish that I went with a fullrace turbo kit from the beginning though. Plus, why can't they re-use components and rebuild the units? Replace the rolling elements and bearings but re-use the housing and compressor wheels. Last edited by projek_01; 04-23-2019 at 01:28 PM. |

|

|

|

|

|

#28 | |

|

Join Date: Jul 2012

Drives: S2000 CR

Location: Orange County

Posts: 14,530

Thanks: 8,920

Thanked 14,177 Times in 6,835 Posts

Mentioned: 966 Post(s)

Tagged: 14 Thread(s)

|

Quote:

I've seen many Rotrex warranty claims denied with the Kraftwerks kit. The Rotrex is not designed to be used with a cogged belt. |

|

|

|

|

| The Following User Says Thank You to CSG Mike For This Useful Post: | wparsons (05-03-2019) |

|

|

|

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Shopping cars today, test drove an fr-s..my thoughts and I'd like more opinions plz. | maybebrz | BRZ First-Gen (2012+) -- General Topics | 55 | 11-04-2015 09:49 AM |

| Thoughts on Kraftwerks C-Type Rotrex Supercharger | Piper606 | Scion FR-S / Toyota 86 GT86 General Forum | 5 | 07-31-2015 09:59 AM |

| FS:CA Brand new never opened KW INOX V3 for sale | stiboost08 | Brakes, Suspension, Chassis | 6 | 07-31-2014 01:18 PM |

| FS/FT: Apple tv! Brand new never opened! | Duthebarber | Miscellaneous | 0 | 10-07-2013 02:34 PM |

| 18x8 Drag DR 38 +35 Never opened | Tdooley | Wheels and Tires | 2 | 02-09-2013 11:42 PM |