Had a little time last night to get some stuff done.

I managed to remove the headlight and seal up the hole left from trimming the housing to fit the intercooler piping. I should have gotten some pictures of the hole as it was large. However, the process/method worked flawlessly.

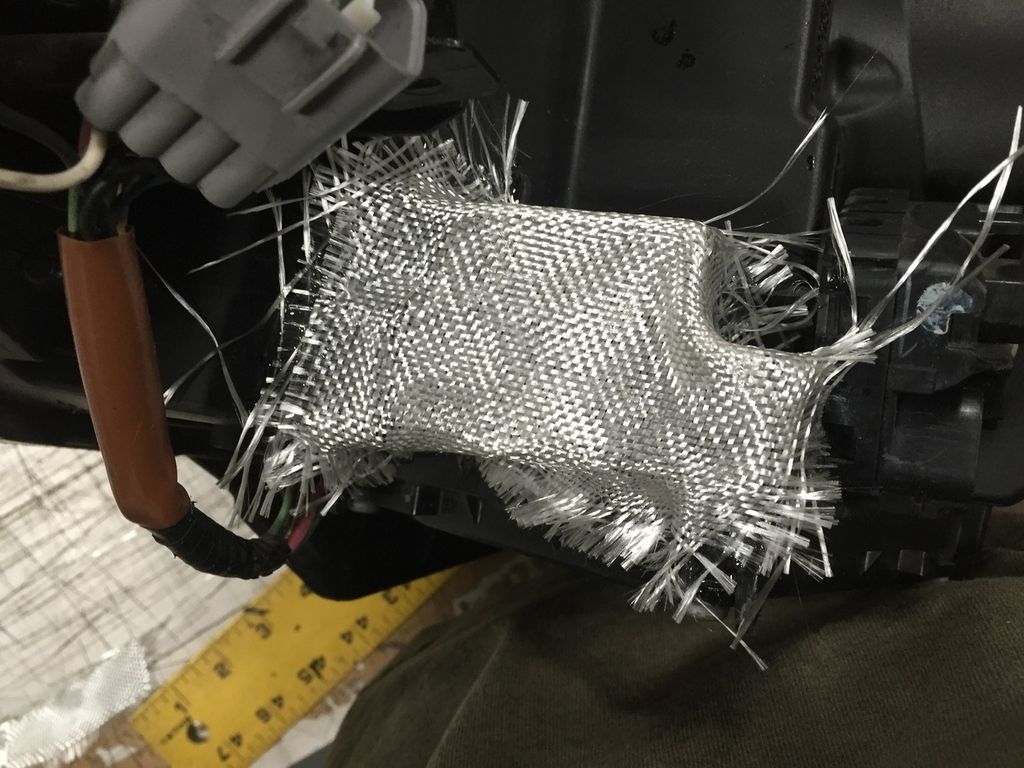

First, I trimmed slightly more plastic off to make the process easier, cleaned and roughened up the edges, then mixed some 5-min epoxy and laid it down around the edge of the hole. I followed this by laying down a square of fiberglass mat over the hole and sealed it at the edges with the epoxy. I then laid down another square of fiberglass. I gave it a couple minutes to set, then laid down a layer of resin over the fiberglass, followed by two more subsequent layers of fiberglass and resin. Looks ugly, but it got the job done!

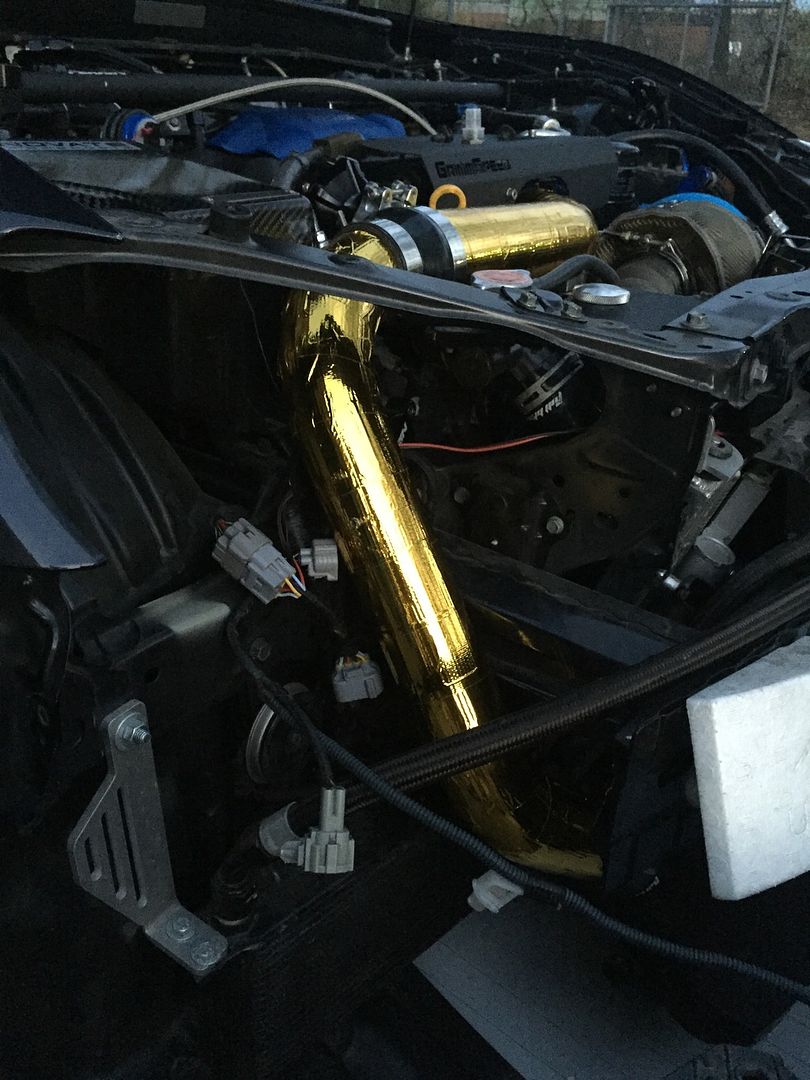

I also pulled the rest of the cold side IC piping and gold wrapped it for a little added heat protection and continuity.

Fortunately, my new fuel lines and brackets came in from FBM, so I painted those as well and got them semi-installed.

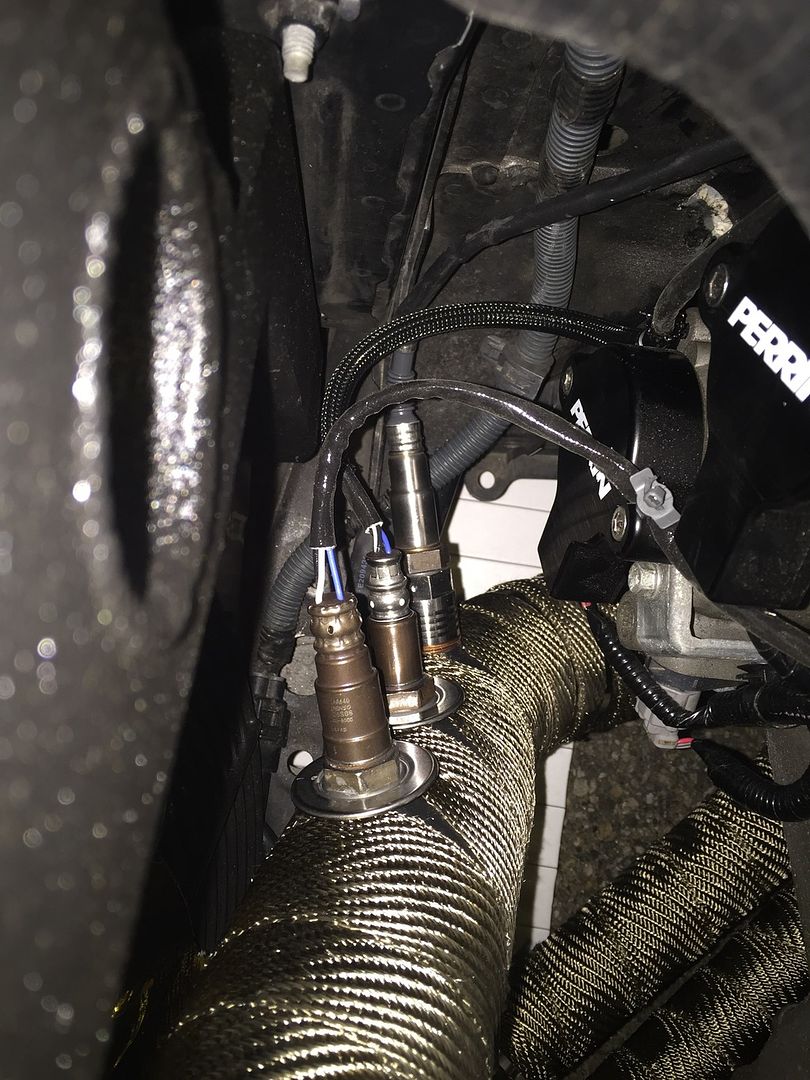

Lastly, I installed the Innovate bung heatsink, as well as the wideband sensor for my new gauge (Ethanol %, Fuel temp, Fuel pressure, and AFR).

Take a look!

Epoxy!

First Layer!

Second Layer!

Done!

Rest of IC piping gold wrapped and re-installed.

New wideband sensor and heatsink installed.

Brackets from FBM touched up, blasted, and painted matte black to match the rest.

I'll be adding the fluids and bleeding the clutch tonight, as well as re-installing the over/front pipe.

After that, just waiting on the driveshaft from DSS and we should be back on the road assuming no issues.

So close!